At its core, mixing technology transforms rotary furnace performance by dramatically enhancing the rates of heat and mass transfer within the material bed. This fundamental improvement allows for greater volume utilization and significantly shorter processing times. The direct result is the ability to meet process requirements with a smaller, more energy-efficient furnace, leading to lower capital and operational costs.

The central challenge in any rotary furnace is uniformly delivering energy and reactants to the entire volume of material. Effective mixing is the engineering solution to this problem, designed to break down thermal and chemical barriers, which leads directly to higher product quality and greater process efficiency.

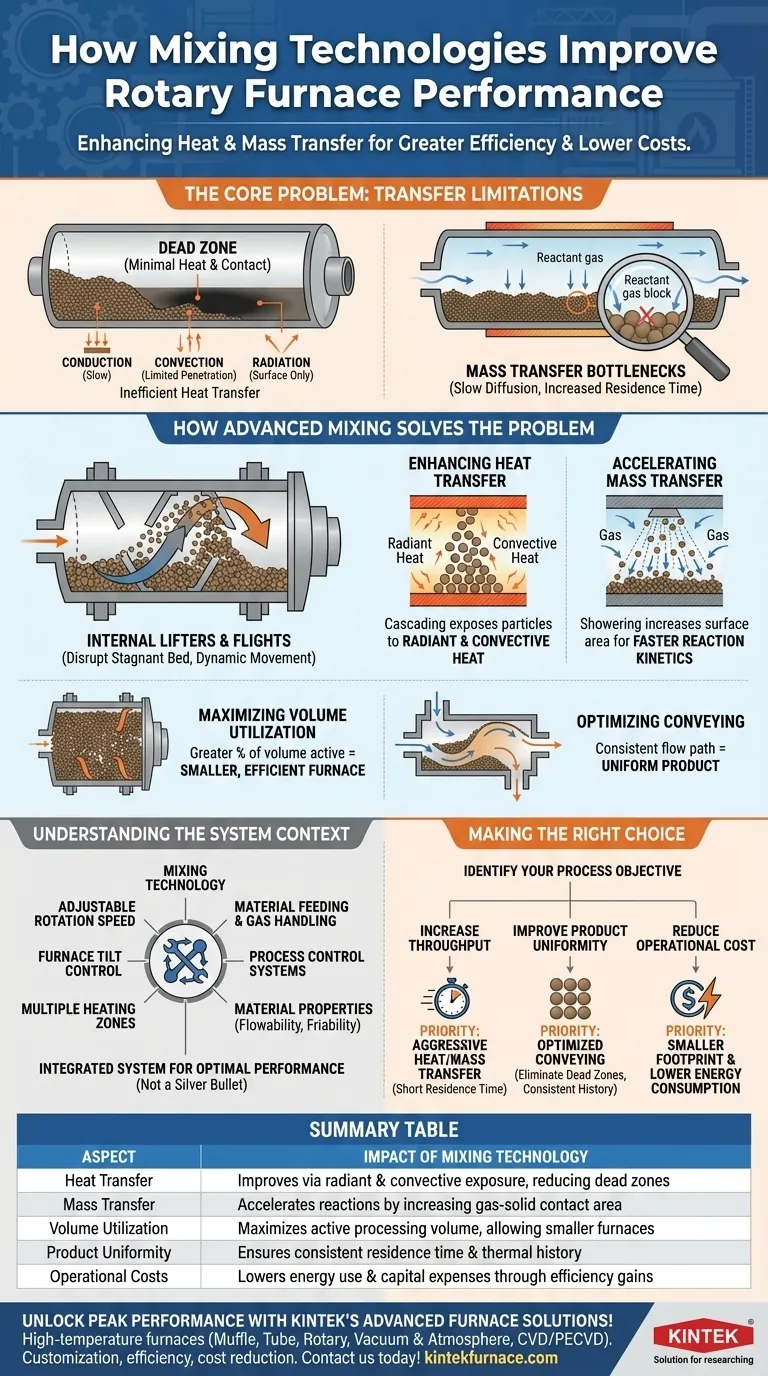

The Core Problem: Transfer Limitations in a Standard Furnace

A simple rotating tube often performs poorly because the material inside does not mix effectively. Without specific mixing technologies, the process becomes limited by the physics of heat and mass transfer, creating inefficiency.

The "Dead Zone" Phenomenon

In a basic furnace, material tends to slide or slump along the bottom of the rotating cylinder. This creates a relatively stationary core of material that is insulated by the surrounding layers.

This "dead zone" receives minimal heat and has poor contact with the process atmosphere, leading to non-uniform product and wasted energy.

Heat Transfer Inefficiency

Heat is transferred in a furnace through conduction (particle-to-particle), convection (from process gas), and radiation (from the hot walls).

Without active mixing, all three modes are inefficient. The stagnant bed limits conduction, prevents hot gases from penetrating the bulk material, and only exposes the top surface layer to radiant heat.

Mass Transfer Bottlenecks

Many processes, such as reduction or calcination, require a chemical reaction between the solid material and a process gas.

If the material is not properly mixed, the gas can only react with the top surface. The process stalls as it waits for the slow diffusion of reactants into and out of the stagnant material bed, dramatically increasing the required residence time.

How Advanced Mixing Solves the Problem

Advanced mixing technologies, such as internal lifters or flights, are designed to disrupt the stagnant material bed and force a more dynamic movement. This directly addresses the core transfer limitations.

Enhancing Heat Transfer

Mixing features repeatedly lift material from the bottom of the bed and cascade it through the hotter, upper volume of the furnace.

This action accomplishes two critical tasks: it continuously exposes new, cooler particles to direct radiant heat from the furnace walls and promotes intimate contact with the process gas for improved convective heat transfer.

Accelerating Mass Transfer

By showering the material through the process atmosphere, mixing ensures that every particle is repeatedly exposed to the reactant gases.

This vastly increases the surface area available for reaction, changing the process from one limited by slow diffusion to one governed by the much faster reaction kinetics.

Maximizing Volume Utilization

Because heat and mass are transferred more effectively, the material reaches its target temperature and reacts more quickly.

This means that a greater percentage of the furnace's internal volume is actively processing material at any given moment. This increased volume utilization is why a smaller, well-mixed furnace can outperform a larger, unmixed one.

Optimizing Conveying for Uniformity

Well-designed mixing internals also ensure optimized conveying of the material from the inlet to the outlet.

This creates a consistent flow path that minimizes back-mixing and stagnant regions, ensuring every particle experiences a nearly identical residence time and thermal history. The result is a highly uniform and consistent final product.

Understanding the Trade-offs and System Context

While critical, mixing technology is one component of a larger, integrated system. Achieving optimal performance requires a holistic view.

Mixing is Not a Silver Bullet

The effectiveness of mixing is tied to other operational parameters. The best results are achieved when mixing is considered alongside adjustable rotation speed, furnace tilt control, and multiple heating zones.

These elements work together to give operators precise control over both residence time and the applied temperature profile.

The Importance of System Design

A truly optimized furnace is more than just a rotating tube. It includes a comprehensive system for material feeding, process gas handling (such as an inert gas package), and sophisticated process control systems to manage all variables.

Material Properties Dictate Design

The choice of mixing technology is highly dependent on the properties of the material being processed. Aggressive lifters that work well for robust ores would cause unacceptable degradation in a fragile or crystalline material.

The design must be tailored to the material's flowability, angle of repose, and friability to prevent product damage or inefficient flow.

Making the Right Choice for Your Process

To apply this understanding to your operation, begin by identifying your single most important process objective.

- If your primary focus is increasing throughput: Prioritize mixing technologies that aggressively enhance heat and mass transfer to shorten the required residence time.

- If your primary focus is improving product uniformity: Select a system with optimized conveying and mixing features that eliminate dead zones and ensure every particle has the same process experience.

- If your primary focus is reducing operational cost: Focus on how enhanced mixing allows for a smaller furnace footprint and lower energy consumption per unit of product.

Ultimately, mastering material mixing is the key to unlocking the full potential of your thermal processing operation.

Summary Table:

| Aspect | Impact of Mixing Technology |

|---|---|

| Heat Transfer | Improves via radiant and convective exposure, reducing dead zones |

| Mass Transfer | Accelerates reactions by increasing gas-solid contact area |

| Volume Utilization | Maximizes active processing volume, allowing smaller furnaces |

| Product Uniformity | Ensures consistent residence time and thermal history |

| Operational Costs | Lowers energy use and capital expenses through efficiency gains |

Unlock peak performance for your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and reducing costs. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing