At their core, laboratory and industrial muffle furnaces are distinguished by their design philosophy: precision versus production. A laboratory furnace is a finely-tuned instrument designed for controlled, repeatable scientific applications on a small scale. In contrast, an industrial furnace is a robust workhorse built for high-volume, continuous operation in a demanding manufacturing environment.

The choice between a laboratory and an industrial muffle furnace is not about which is superior, but about aligning the equipment's primary function—either precise process control or high-volume throughput—with your specific operational goal.

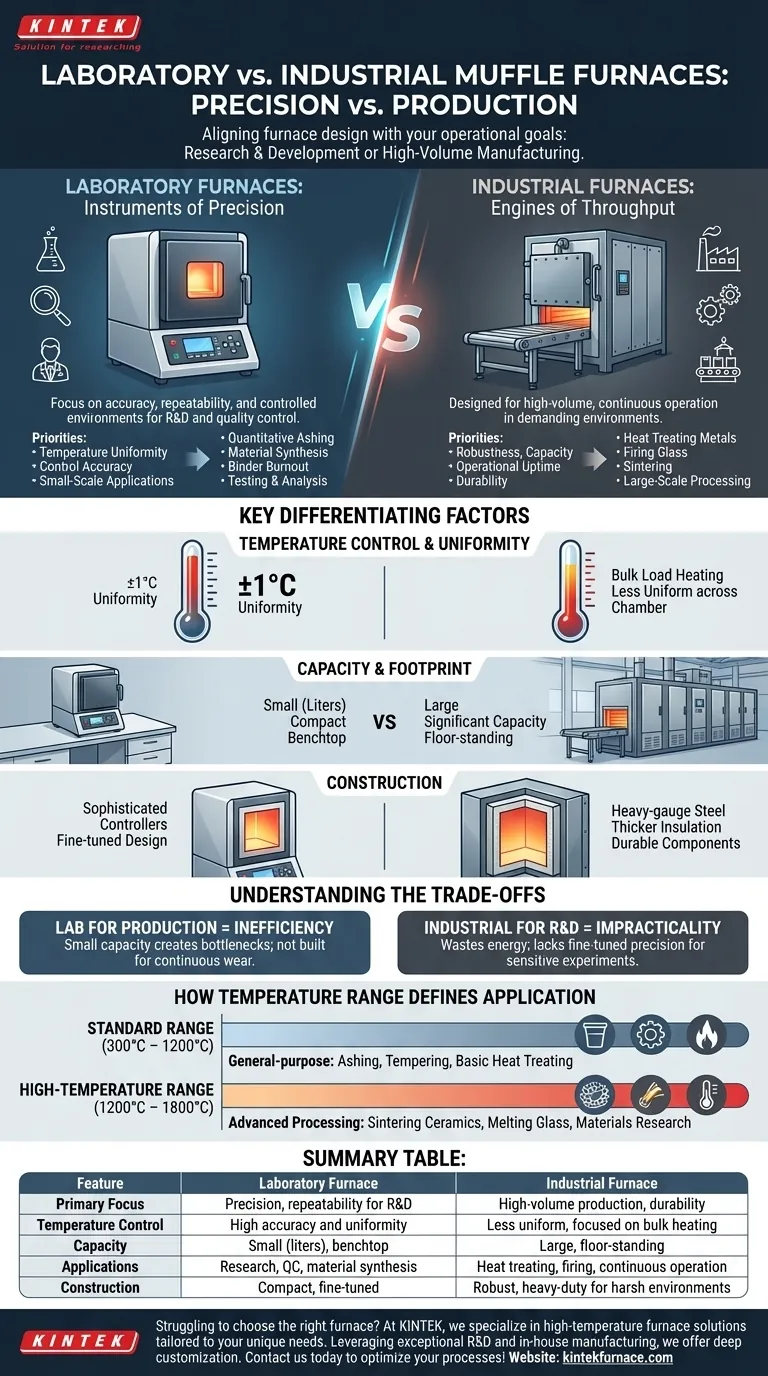

The Core Design Philosophy: Precision vs. Production

The fundamental difference between these two types of furnaces lies in the problems they are engineered to solve.

Laboratory Furnaces: Instruments of Precision

Laboratory furnaces are designed for research, development, and quality control where accuracy is paramount. Their purpose is to create a perfectly controlled and repeatable thermal environment for testing and analysis.

Applications like quantitative ashing, material synthesis, or binder burnout demand exact temperature ramps and uniform heat distribution to ensure the validity of an experiment. These units prioritize temperature uniformity and control accuracy above all else.

Industrial Furnaces: Engines of Throughput

Industrial furnaces are integral components of a production line. Their primary goal is to process large quantities of material efficiently and reliably, day after day.

These units are built for durability in harsh environments, handling processes like heat treating metals or firing glass at a large scale. The focus is on robustness, capacity, and operational uptime rather than the micro-level precision required in a lab.

Key Differentiating Factors

While both use a heated chamber (muffle) to isolate materials from direct heating elements or contaminants, their construction reflects their divergent purposes.

Temperature Control and Uniformity

A key differentiator is the precision of the temperature controller and the resulting heat uniformity within the chamber.

Laboratory models feature sophisticated controllers and designs that minimize temperature gradients, ensuring a sample is heated evenly. This is critical for reliable scientific results. Industrial models ensure the bulk load reaches the setpoint, but may have less uniformity across the larger chamber.

Capacity and Physical Footprint

The most obvious difference is size. Laboratory furnaces are typically compact, benchtop units with chamber volumes measured in liters.

Industrial furnaces are large, floor-standing machines with significant capacity, designed to integrate into a manufacturing workflow. Their size is dictated by the required throughput of the production process.

Heating Elements and Construction

Both types often use electrical heating elements, such as iron-chrome alloys, to provide clean, controllable heat without combustion byproducts.

However, industrial furnaces are built with heavier-gauge steel, thicker insulation, and more durable components to withstand the mechanical stress and continuous thermal cycling of a production schedule.

Understanding the Trade-offs

Choosing the wrong type of furnace leads to inefficiency, poor results, and unnecessary costs.

The Cost of Precision

Using a laboratory furnace for production-level tasks is highly inefficient. Its small capacity creates a bottleneck, and its design is not intended for the wear and tear of continuous, high-throughput operation.

The Limitations of Scale

Conversely, using a large industrial furnace for a small, sensitive experiment is impractical. It wastes significant energy to heat the large chamber and lacks the fine-tuned temperature uniformity needed for precise analytical work.

How Temperature Range Defines Application

The required temperature is a primary factor in selecting a furnace, as it dictates the types of applications possible.

Standard Range (300°C – 1200°C)

Furnaces in this range are common in both lab and industrial settings for general-purpose work. Typical applications include ashing organic materials, tempering steel, and basic heat-treating processes.

High-Temperature Range (1200°C – 1800°C)

High-temperature models are specialized for advanced materials processing. These are necessary for sintering technical ceramics, melting certain glasses, or conducting materials research under extreme thermal stress.

Making the Right Choice for Your Goal

Your final decision must be guided by the primary goal of your operation.

- If your primary focus is research and development: Choose a laboratory furnace for its superior temperature precision and uniformity.

- If your primary focus is small-batch or specialized production: A larger laboratory furnace or a small industrial model may provide the right balance of control and capacity.

- If your primary focus is high-volume manufacturing: Choose a robust industrial furnace designed for throughput and durability.

Ultimately, matching the furnace's inherent design to your specific application is the only way to ensure optimal performance and a successful outcome.

Summary Table:

| Feature | Laboratory Furnace | Industrial Furnace |

|---|---|---|

| Primary Focus | Precision, repeatability for R&D | High-volume production, durability |

| Temperature Control | High accuracy and uniformity | Less uniform, focused on bulk heating |

| Capacity | Small (liters), benchtop | Large, floor-standing |

| Applications | Research, quality control, material synthesis | Heat treating, firing, continuous operation |

| Construction | Compact, fine-tuned | Robust, heavy-duty for harsh environments |

Struggling to choose the right furnace for your lab or production line? At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental or production requirements, enhancing efficiency and reliability. Contact us today to discuss how our advanced furnaces can optimize your processes and deliver superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites