At its core, advanced mixing and conveying technologies improve rotary furnace performance by fundamentally changing how material interacts with heat and the process atmosphere. Instead of passively tumbling, these systems actively manage material flow to maximize heat and mass transfer, which in turn reduces process time, increases volume utilization, and ensures a highly uniform final product. This allows for smaller, more efficient furnace designs that can outperform larger, less sophisticated units.

The central challenge in any rotary furnace is overcoming inefficient, passive material tumbling. Advanced mixing and conveying technologies solve this by transforming the furnace from a simple container into an engineered environment that actively forces every particle to be processed uniformly.

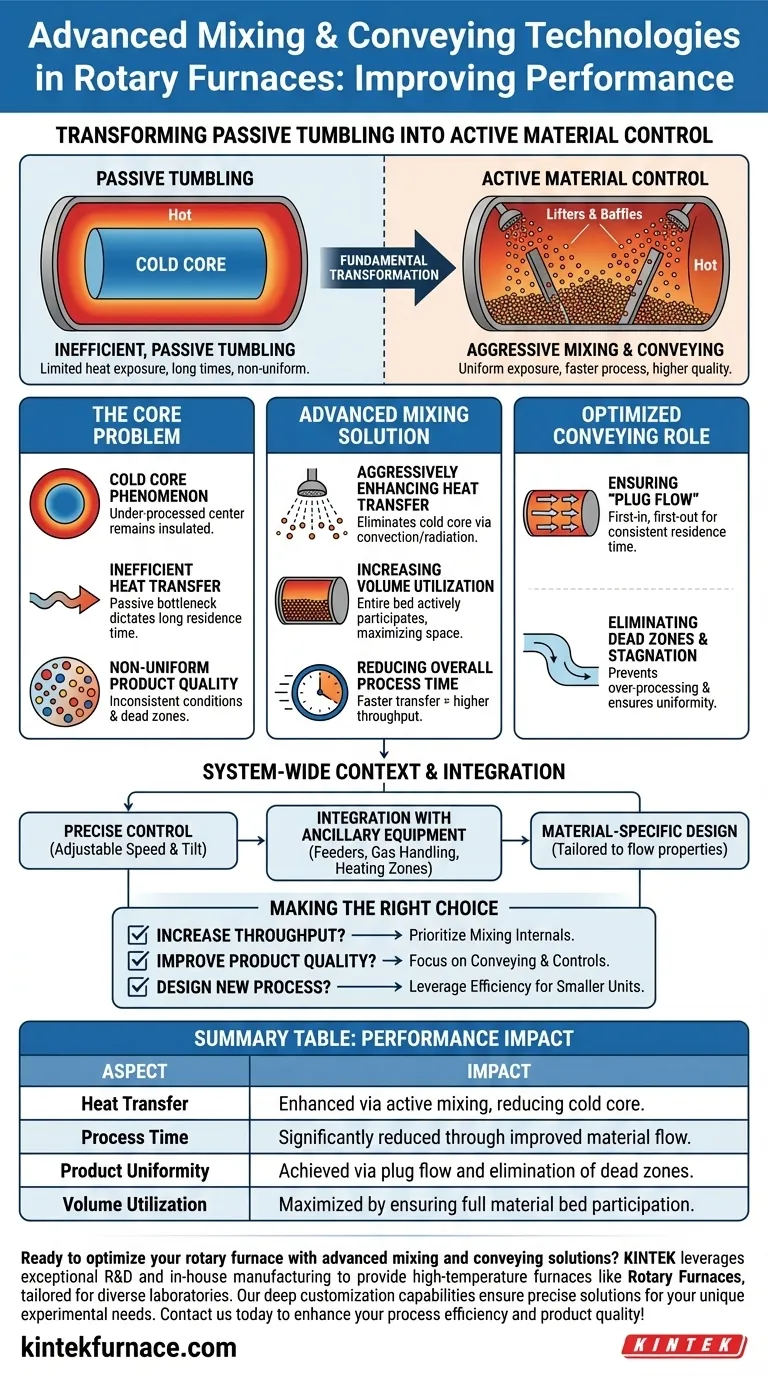

The Core Problem: Limitations of Passive Tumbling

In a basic rotary furnace, material simply tumbles over itself as the drum rotates. This seemingly simple action creates significant process inefficiencies that limit performance and quality.

The "Cold Core" Phenomenon

As the material bed tumbles, only the top layer is directly exposed to the heat source and process gas. The material in the center of the bed remains insulated, creating a "cold core" that is under-processed.

Inefficient Heat and Mass Transfer

Heat can only penetrate the material bed slowly via conduction from the exposed surface layer. This passive transfer is a major bottleneck, dictating a long residence time to ensure the entire volume reaches the target temperature.

Non-Uniform Product Quality

The combination of a hot outer layer and a cool inner core means particles experience vastly different conditions. Furthermore, variations in flow can create dead zones where material lingers, or channels where it passes through too quickly, resulting in a non-uniform final product.

How Advanced Mixing Transforms the Process

Advanced mixing technologies directly attack the "cold core" problem by forcing the material bed to turn over on itself, ensuring every particle gets its turn at the surface.

Aggressively Enhancing Heat Transfer

Internal structures like lifters, baffles, or custom agitators are designed to lift material from the bottom of the bed and shower it through the hot atmosphere in the upper portion of the furnace. This dramatically increases heat and mass transfer by convection and radiation, nearly eliminating the cold core.

Increasing Effective Volume Utilization

By ensuring the entire cross-section of the material bed is actively participating in the reaction, you are using the furnace's internal volume far more effectively. A process limited by heat transfer can now happen much faster within the same physical space.

Reducing Overall Process Time

Because heat is transferred to the material much more quickly, the required residence time to complete the process is significantly reduced. This directly translates to higher throughput for an existing furnace or allows for a smaller, more cost-effective furnace in a new design.

The Role of Optimized Conveying

While mixing addresses how material behaves within a cross-section of the furnace, conveying addresses how it moves from the inlet to the outlet.

Ensuring "Plug Flow"

Optimized conveying, often using features like an adjustable tilt angle or internal helical flights, aims to move material through the furnace in a "first-in, first-out" manner known as plug flow. This ensures every particle spends a similar amount of time inside the furnace.

Eliminating Dead Zones and Stagnation

Poor conveying design leads to dead zones where material can get stuck or recycle, leading to over-processing and non-uniformity. Proper conveying design ensures a smooth, continuous, and predictable flow from end to end.

Driving Product Uniformity

When every particle experiences both uniform mixing (consistent heat exposure) and uniform conveying (consistent residence time), the result is a final product with exceptional uniformity and quality.

Understanding the System-Wide Context

Implementing these advanced features is not a simple plug-and-play upgrade. Success requires viewing the furnace as an integrated system.

The Need for Precise Control

Advanced internals are most effective when paired with precise process controls. Adjustable rotation speed and furnace tilt allow operators to fine-tune the mixing and conveying action for different materials or process stages.

Integration with Ancillary Equipment

The performance of the furnace is dependent on the entire system. This includes consistent material feeding from feeders, managing the internal atmosphere with gas handling packages, and controlling temperature precisely with multiple heating zones.

Design is Material-Specific

A mixing design that works perfectly for a free-flowing granular solid will fail completely with a sticky or sludge-like material. The design of mixing and conveying internals must be tailored to the specific properties of the material being processed.

Making the Right Choice for Your Goal

Your specific objective will determine which technological enhancements to prioritize.

- If your primary focus is increasing throughput: Prioritize advanced mixing internals that maximize heat and mass transfer to slash process times.

- If your primary focus is improving product quality: Concentrate on optimized conveying and precise process controls to ensure uniform residence time and eliminate dead zones.

- If your primary focus is designing a new, compact process line: Leverage the efficiency gains from both mixing and conveying to specify a smaller, less capital-intensive furnace that meets your output goals.

By moving from passive tumbling to active material control, you transform the rotary furnace from a simple vessel into a precision processing instrument.

Summary Table:

| Aspect | Impact |

|---|---|

| Heat Transfer | Enhanced via active mixing, reducing cold core and increasing efficiency |

| Process Time | Significantly reduced through improved material flow and heat exposure |

| Product Uniformity | Achieved via plug flow and elimination of dead zones for consistent quality |

| Volume Utilization | Maximized by ensuring full material bed participation in reactions |

Ready to optimize your rotary furnace with advanced mixing and conveying solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Rotary Furnaces, tailored for diverse laboratories. Our deep customization capabilities ensure precise solutions for your unique experimental needs. Contact us today to enhance your process efficiency and product quality!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing