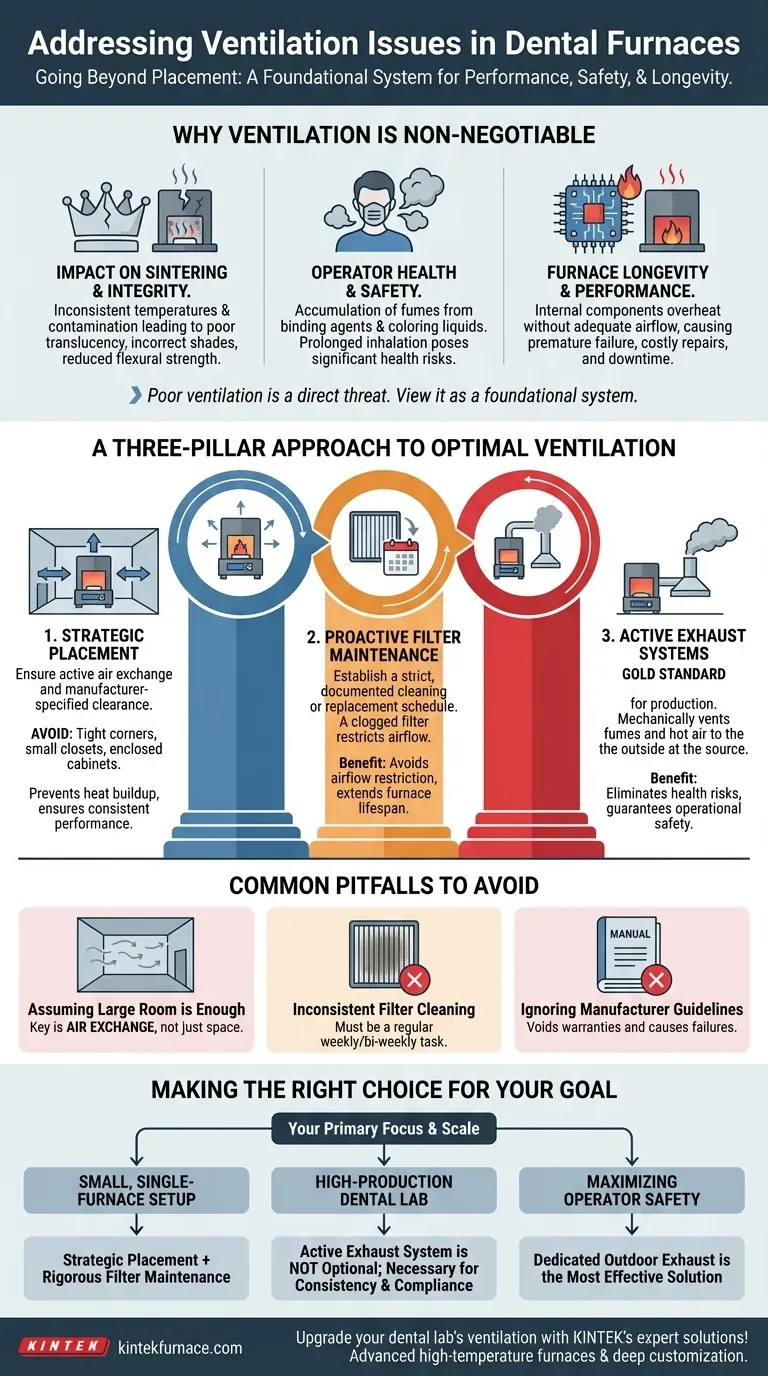

To properly address ventilation issues, you must go beyond simply placing the furnace in a room. The solution involves three key actions: ensuring placement in an area with active air exchange, performing regular and disciplined filter maintenance, and for most professional settings, installing a dedicated exhaust system to actively remove fumes and heat at the source.

Poor furnace ventilation is not merely an inconvenience; it is a direct threat to the integrity of your restorations, the health of your team, and the lifespan of your equipment. Viewing ventilation as a foundational system, rather than a single checklist item, is the key to resolving these issues permanently.

Why Ventilation is Non-Negotiable for Dental Furnaces

Understanding the consequences of inadequate airflow is the first step toward building a reliable and safe laboratory environment. The problems extend far beyond a noticeable odor.

Impact on Sintering and Material Integrity

Poor ventilation traps heat and fumes inside the furnace chamber. This can lead to inconsistent temperatures and atmospheric contamination during the critical sintering or firing cycle.

The result is often compromised material quality, leading to restorations with poor translucency, incorrect shades, or reduced flexural strength.

Operator Health and Safety

Sintering zirconia and firing ceramics can release fumes from binding agents and coloring liquids. In a poorly ventilated space, these airborne contaminants accumulate.

Prolonged inhalation of these fumes can pose significant health risks to lab technicians and dental staff, making proper air quality a critical workplace safety issue.

Furnace Longevity and Performance

Dental furnaces contain sensitive electronic components that generate significant heat. Proper ventilation is essential for dissipating this heat effectively.

Without adequate airflow, internal components can overheat, leading to premature failure, costly repairs, and unexpected downtime.

A Three-Pillar Approach to Optimal Ventilation

A robust ventilation strategy is built on three distinct but interconnected pillars. Implementing all three ensures a comprehensive solution.

Pillar 1: Strategic Placement

The furnace must be installed in a room with good ambient airflow, not just a large room. Avoid placing the unit in a tight corner, a small closet, or an enclosed cabinet.

Ensure there is clearance on all sides of the furnace as specified by the manufacturer to allow its internal fans to operate without obstruction.

Pillar 2: Proactive Filter Maintenance

Most furnaces have ventilation filters that trap dust and debris. These filters are your first line of defense but are often neglected.

A clogged filter is worse than no filter, as it actively restricts airflow and forces the furnace's cooling systems to work harder. Check and clean or replace these filters according to a strict, documented maintenance schedule.

Pillar 3: Active Exhaust Systems

For any serious production environment, an active exhaust system is the gold standard. This involves a hood or direct connection that mechanically vents fumes and hot air to the outside.

This is the only method that guarantees fumes are removed at the source, preventing them from ever entering the lab's atmosphere. It provides the highest level of safety and operational consistency.

Common Pitfalls to Avoid

Achieving effective ventilation requires avoiding common but critical mistakes that undermine the entire system.

Pitfall: Assuming a Large Room is Enough

A large room with stagnant air is not "well-ventilated." The critical factor is air exchange—the rate at which stale indoor air is replaced with fresh outdoor air. Without fans, open windows, or an HVAC system promoting exchange, fumes will still concentrate.

Pitfall: Inconsistent Filter Cleaning

Forgetting to clean the ventilation filter for a few cycles can be enough to impede airflow. This should be part of a weekly or bi-weekly checklist, not an occasional task. A clogged filter puts direct strain on the furnace's internal components.

Pitfall: Ignoring Manufacturer Guidelines

Every furnace model has specific requirements for clearance and airflow detailed in its installation manual. Ignoring these specifications voids warranties and is a direct cause of performance issues and premature equipment failure.

Making the Right Choice for Your Goal

Your ventilation strategy should match the scale and priorities of your operation.

- If your primary focus is a small, single-furnace setup: Begin with strategic placement in a room with active air exchange and implement a rigorous filter maintenance schedule.

- If your primary focus is a high-production dental lab: An active exhaust system is not optional; it is a necessary investment for consistent clinical results and regulatory compliance.

- If your primary focus is maximizing operator safety: A dedicated exhaust system that vents directly to the outdoors is the most effective solution for eliminating exposure to harmful fumes.

Ultimately, treating ventilation as an integral part of your production workflow is fundamental to achieving predictable, high-quality results safely.

Summary Table:

| Ventilation Pillar | Key Actions | Benefits |

|---|---|---|

| Strategic Placement | Place in area with active air exchange; follow manufacturer clearance | Prevents heat buildup, ensures consistent performance |

| Filter Maintenance | Clean/replace filters regularly on a strict schedule | Avoids airflow restriction, extends furnace lifespan |

| Active Exhaust System | Install dedicated exhaust to vent fumes and heat outdoors | Eliminates health risks, guarantees operational safety |

Upgrade your dental lab's ventilation with KINTEK's expert solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, and Rotary Furnaces, along with deep customization to meet your unique needs. Ensure optimal performance and safety—contact us today for a tailored consultation!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision