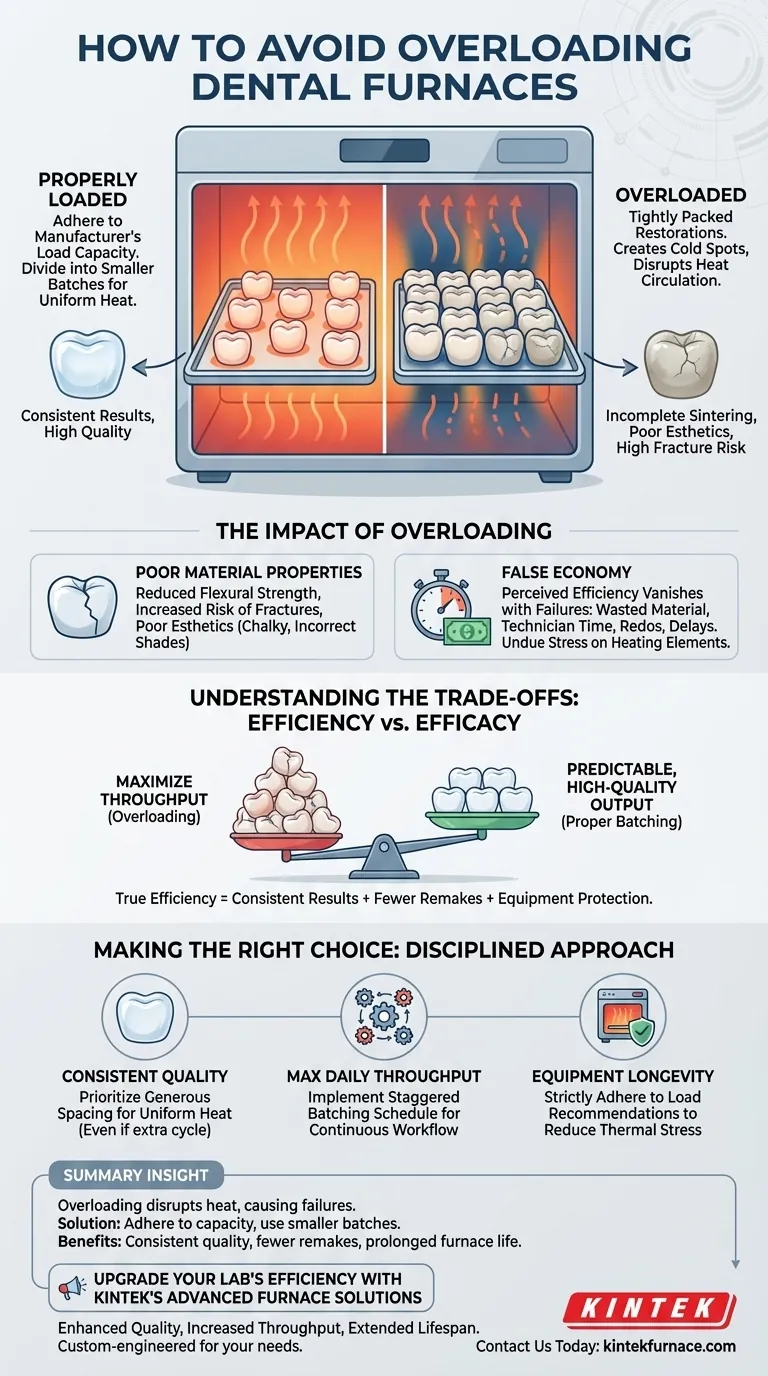

To avoid overloading a dental furnace, you must strictly adhere to the manufacturer's recommended load capacity and, when processing multiple items, divide them into separate, smaller batches. This discipline is not just about weight but about ensuring adequate space for uniform heat circulation around every restoration.

The core issue with overloading is not the physical strain on the furnace tray, but the disruption of uniform heat. Tightly packed restorations create cold spots, leading to incomplete sintering, compromised material strength, and ultimately, failed clinical outcomes.

The Core Problem: Impeded Heat Circulation

Overloading a furnace chamber directly compromises the sintering process by creating an environment of uneven heat. This is the root cause of many common restoration failures.

Why Overloading Disrupts Sintering

Modern dental furnaces rely on consistent radiant and convective heat to achieve uniform temperatures throughout the firing chamber.

When restorations are packed too closely, they block this heat flow. This creates "heat shadows" and significant temperature variations within the chamber.

The Impact on Material Properties

Inconsistent heating leads to incomplete sintering in the cooler zones. This results in restorations with poor esthetics, such as low translucency, incorrect shades, or a chalky appearance.

More critically, it severely compromises the material's flexural strength, increasing the risk of fractures once the restoration is in service.

The "Shadowing" Effect

Think of the furnace's heating elements like a light bulb. A restoration placed too close to another will cast a "heat shadow," preventing the one behind it from receiving the full, direct thermal energy required for proper vitrification and densification.

Understanding the Trade-offs

In a busy dental lab, the pressure to maximize throughput is constant. However, the attempt to save time by overloading a furnace is a false economy that introduces significant risk.

The Lure of Maximum Throughput

The desire to sinter as many units as possible in a single cycle is understandable. It appears to be the most efficient use of time and energy.

The True Cost of Overloading

This perceived efficiency vanishes the moment a batch fails. The cost of a single failed restoration—including wasted material, technician time for a complete redo, and delayed delivery—far outweighs any time saved by overloading.

Furthermore, consistently running the furnace at maximum capacity with restricted airflow can place undue stress on the heating elements, potentially shortening their operational lifespan.

Efficiency vs. Efficacy

True laboratory efficiency is measured by predictable, high-quality output. A strategy of running smaller, properly spaced batches is more effective because it guarantees consistent results, eliminates costly remakes, and protects your equipment investment.

Making the Right Choice for Your Lab

Adopting a disciplined approach to furnace loading is fundamental to achieving consistent, high-quality results. Your specific priority will determine your exact strategy.

- If your primary focus is consistent quality and esthetics: Prioritize generous spacing between units to guarantee uniform heat exposure, even if it requires an extra firing cycle.

- If your primary focus is maximizing daily throughput: Implement a staggered batching schedule with multiple, smaller loads to maintain a continuous workflow without sacrificing the quality of any single unit.

- If your primary focus is equipment longevity: Strictly adhere to the manufacturer's load recommendations to reduce thermal stress on heating elements, preventing premature failure and expensive repairs.

Proper furnace loading is the foundation of predictable and successful restorative dentistry.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Core Problem | Overloading disrupts heat circulation, causing uneven sintering and restoration failures. |

| Impact | Leads to poor esthetics, reduced flexural strength, and increased risk of fractures. |

| Solution | Adhere to manufacturer load capacity, use smaller batches for uniform heat exposure. |

| Benefits | Ensures consistent quality, prevents costly remakes, and prolongs furnace life. |

Upgrade Your Dental Lab's Efficiency with KINTEK's Advanced Furnace Solutions

Are you struggling with furnace overloading issues that lead to failed restorations and wasted resources? At KINTEK, we specialize in providing high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we can design furnaces that precisely meet your unique experimental and production needs, ensuring optimal heat distribution and load management.

By partnering with us, you'll benefit from:

- Enhanced Restoration Quality: Achieve uniform sintering for superior esthetics and strength.

- Increased Throughput: Implement efficient batching without compromising on results.

- Extended Equipment Lifespan: Reduce thermal stress with reliable, custom-engineered solutions.

Don't let overloading hold back your lab's potential. Contact us today to discuss how KINTEK can help you optimize your processes and deliver flawless dental restorations consistently!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns