In short, the two primary methods for increasing the deposition rate in Plasma-Enhanced Chemical Vapor Deposition (PECVD) are to increase the plasma power or to increase the flow rate of the precursor gas. Elevating the power provides more energy to break down the precursor molecules into reactive species, while a higher gas flow increases the supply of these reactants to the substrate surface, both of which accelerate film growth.

The challenge is not simply maximizing the deposition rate, but achieving a higher rate without compromising the essential properties of the thin film. A faster process often introduces trade-offs in film quality, such as higher stress, lower density, or poor uniformity.

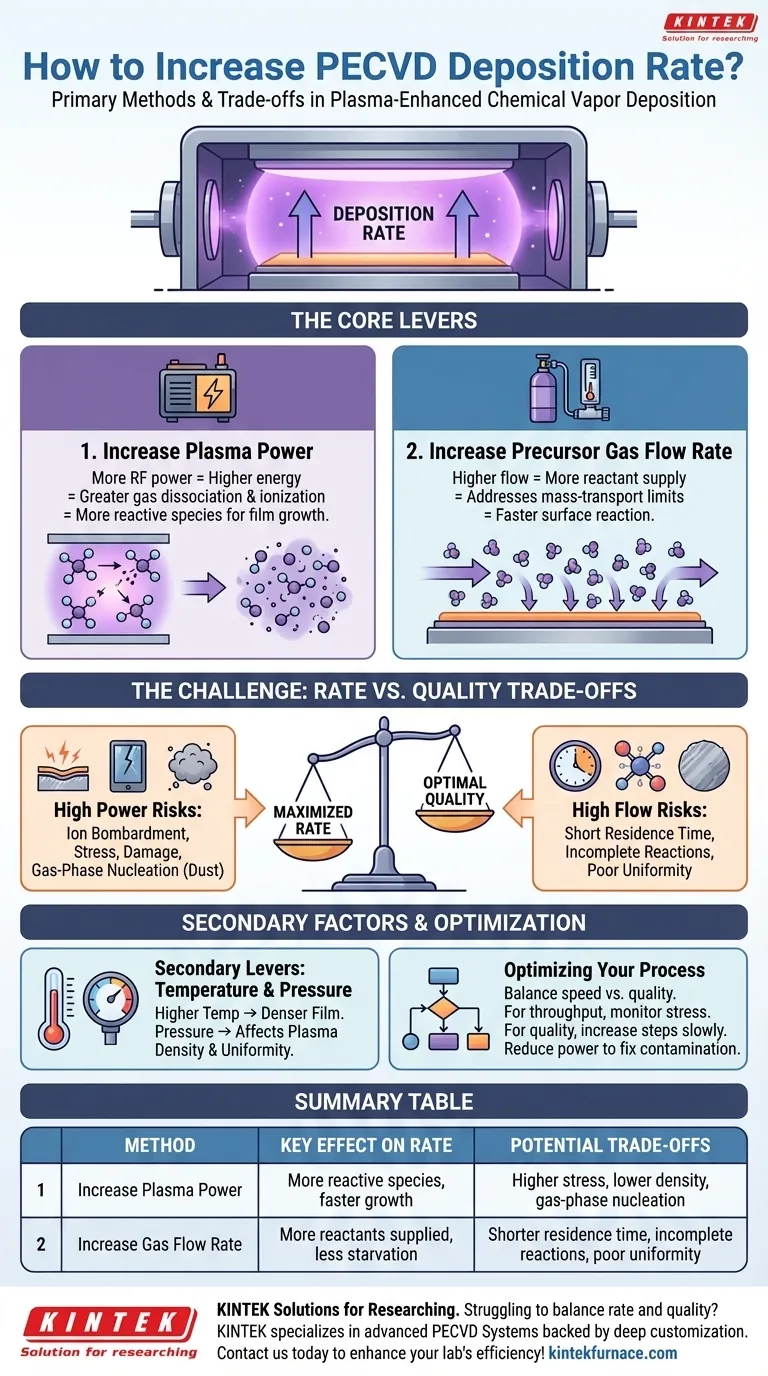

The Core Levers for Increasing Deposition Rate

To effectively control your PECVD process, you must understand how the primary input parameters directly influence the speed of film formation. These levers operate on different aspects of the plasma and chemical reaction environment.

Increasing Plasma Power

Increasing the RF power applied to the electrodes directly injects more energy into the plasma. This has a significant effect on the precursor gases.

This higher energy state leads to a greater degree of dissociation and ionization of the gas molecules. The result is a much higher density of the reactive free radicals and ions that are the building blocks of the thin film, leading to a faster deposition rate.

Increasing Precursor Gas Flow Rate

Increasing the flow rate of the precursor gas (e.g., silane for silicon deposition) ensures a richer supply of reactant molecules is available within the chamber.

This is particularly important in a mass-transport-limited regime, where the reaction rate is faster than the rate at which reactants can be supplied to the substrate. By increasing the flow, you ensure the surface reaction is not "starved" for material, directly increasing the deposition rate.

Understanding the Trade-offs: Rate vs. Quality

Simply turning up the power and flow to their maximums is rarely the optimal solution. Pushing the deposition rate too high can have significant negative consequences for the quality and integrity of your deposited film.

The Impact of High Power

While higher power boosts the rate, it also intensifies ion bombardment on the substrate surface. This can induce compressive stress in the film, cause physical damage to sensitive device layers, and even reduce film density.

Furthermore, excessively high power can lead to gas-phase nucleation. This is where particles of the film material form in the plasma itself, not on the substrate. These particles then fall onto your substrate as dust, creating a rough, contaminated, and often useless film.

The Impact of High Gas Flow

A very high gas flow rate reduces the residence time—the average time a molecule spends within the plasma zone. If the residence time is too short, the precursor molecules may not have enough time to dissociate completely.

This can lead to incomplete chemical reactions and the incorporation of undesirable byproducts (like excess hydrogen in silicon nitride films) into the film, altering its electrical and optical properties. It can also degrade film uniformity across the wafer if the gas does not distribute evenly.

The Role of Temperature and Pressure

While power and flow are primary levers, substrate temperature and chamber pressure are critical secondary parameters. Higher temperature provides surface atoms with more energy to move around, generally leading to a denser, higher-quality film. Pressure affects the plasma density and the mean free path of molecules, influencing both the reaction chemistry and the uniformity of deposition.

Optimizing Your PECVD Process

Your ideal parameters are a function of your specific goal. You must balance the need for speed against the non-negotiable requirements for film quality.

- If your primary focus is maximum throughput: Carefully increase plasma power and gas flow in tandem, but diligently monitor film properties like stress, uniformity, and defect count to find the point of unacceptable degradation.

- If your primary focus is high film quality (e.g., for optical or electronic devices): Begin with a conservative, well-known recipe. Increase one parameter at a time in small increments, measuring film properties like refractive index, density, and etch rate at each step to characterize the process window.

- If you are struggling with film contamination or dust: Your plasma power is likely too high, causing gas-phase nucleation. Reduce power or adjust pressure to mitigate this effect.

Mastering your PECVD process comes from understanding that every parameter adjustment involves a calculated trade-off.

Summary Table:

| Method | Key Effect on Deposition Rate | Potential Trade-offs |

|---|---|---|

| Increase Plasma Power | Higher energy leads to more reactive species, accelerating film growth | Higher stress, lower density, gas-phase nucleation, contamination |

| Increase Gas Flow Rate | More reactants supplied, reducing starvation in mass-transport-limited regimes | Shorter residence time, incomplete reactions, poor uniformity |

Struggling to balance deposition rate and film quality in your PECVD processes? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing. Our deep customization capabilities ensure we can tailor systems to meet your unique experimental needs, helping you achieve optimal performance without compromising on quality. Contact us today to discuss how we can enhance your laboratory's efficiency and results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition