In short, yes. Chemical Vapor Deposition (CVD) furnaces are highly customizable to meet specific application requirements. Customization can range from modifying standard models with specific modules to designing a completely bespoke system from the ground up, allowing for precise control over the core parameters that define your process.

True customization of a CVD furnace goes beyond simply selecting options. It is a collaborative engineering process that aligns the system's core components—such as the reaction chamber, heating system, gas delivery, and vacuum—with the precise chemical and physical demands of your unique deposition goal.

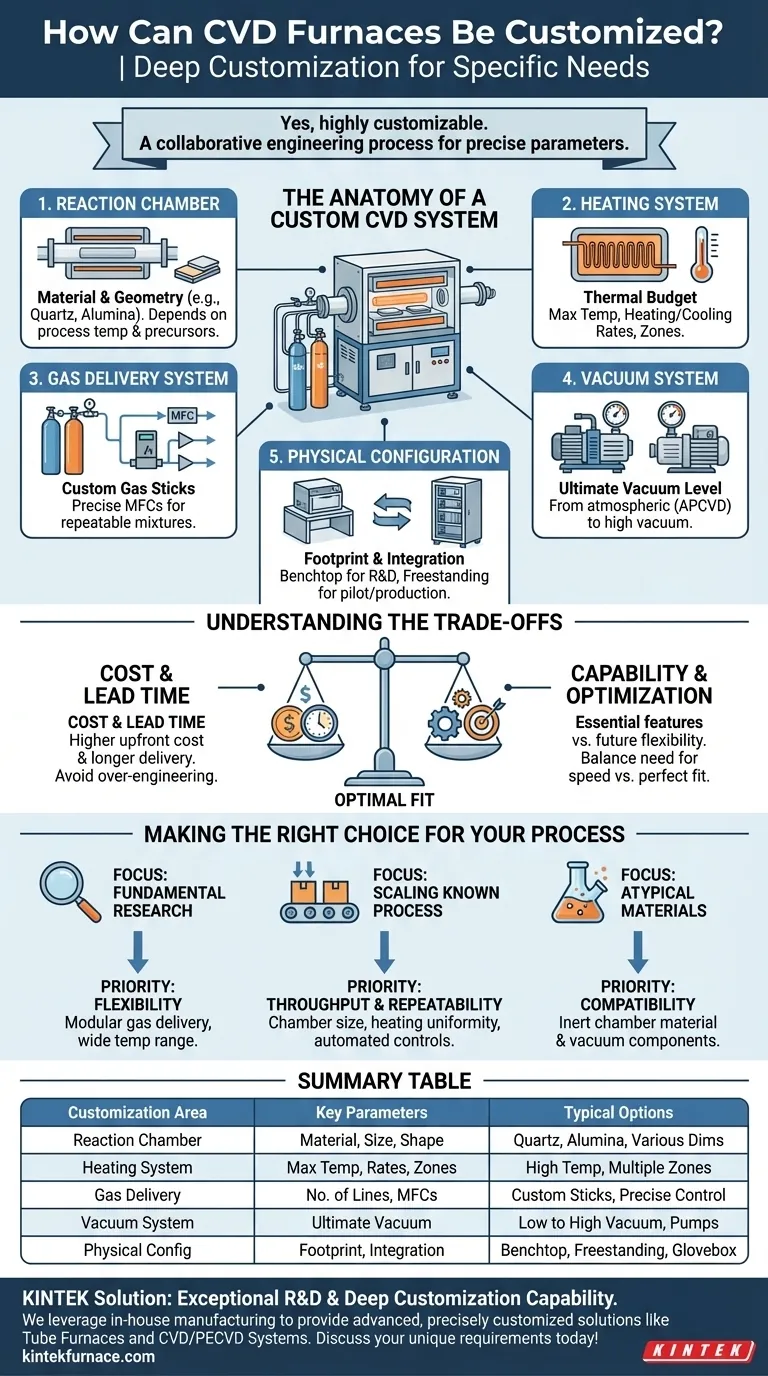

The Anatomy of a Custom CVD System

A CVD furnace is a system of integrated components, each of which can be tailored to your needs. Understanding these subsystems is the first step in defining your requirements.

The Reaction Chamber

The heart of the system is the reaction chamber, where deposition occurs. Customization here focuses on material compatibility and geometry.

Suppliers can provide furnace tubes and chambers in various sizes, shapes, and materials, such as quartz or alumina ceramic. The choice depends entirely on your process temperature and chemical precursors.

The Heating System

The heating system dictates the thermal budget of your process. Key parameters are all configurable.

You can specify the maximum temperature, heating and cooling rates, and the number of heating zones. This ensures the furnace can execute the precise thermal profile your material synthesis requires.

The Gas Delivery System

CVD is defined by its precursor gases, making this system critical. You are not limited to off-the-shelf configurations.

Engineers can design custom gas control modules, often called "gas sticks," with a specific number of lines for different precursors and carrier gases. Each line is typically outfitted with a precise mass flow controller (MFC) to guarantee repeatable gas mixtures.

The Vacuum System

The process pressure is a fundamental control parameter. The vacuum system is designed to meet this need.

Customization includes selecting the right combination of pumps to achieve the ultimate vacuum level required, from low vacuum for atmospheric pressure CVD (APCVD) to high vacuum for more sensitive processes.

Physical Configuration and Footprint

The furnace must fit your lab space and workflow.

Systems can be designed as compact benchtop units for research and development or as larger, freestanding systems for pilot-scale or production work. They can also be built to integrate with other equipment, such as gloveboxes or analytical tools.

Understanding the Trade-offs

While customization offers immense capability, it requires careful consideration of the inherent trade-offs. An objective assessment is necessary to avoid costly errors.

Cost vs. Capability

A fully custom system will have a higher upfront cost than a standard model. The key is to avoid over-engineering.

Work closely with application engineers to ensure you are only paying for the features essential to your process, not for capabilities you will never use.

Lead Time vs. Urgency

Custom manufacturing takes time. Design, fabrication, and testing can add weeks or months to your delivery schedule.

If your project is on a tight deadline, a standard or lightly modified system might be a more practical choice. Balance the need for a perfect fit against the need for timely results.

Flexibility vs. Optimization

A system highly optimized for one specific process may be less suitable for future, different experiments.

Consider the long-term goals of your lab. A more modular and flexible design might be a wiser investment for fundamental research, while a highly optimized system is better for scaling a single, well-defined process.

Making the Right Choice for Your Process

The ideal furnace configuration depends entirely on your end goal. Begin the conversation with suppliers by clearly defining your process requirements, not by listing hardware.

- If your primary focus is fundamental research: Prioritize flexibility with modular gas delivery systems and a wide operational temperature range to explore new materials and processes.

- If your primary focus is scaling a known process: Concentrate on optimizing chamber size for throughput, heating uniformity for consistent results, and automated controls for repeatability.

- If your primary focus is working with atypical materials: Specify a chamber material and vacuum system components that are chemically inert to your specific precursors.

Ultimately, a successful customization is the direct result of a clearly defined process and close collaboration with expert engineers.

Summary Table:

| Customization Area | Key Parameters | Typical Options |

|---|---|---|

| Reaction Chamber | Material, Size, Shape | Quartz, Alumina, Various Dimensions |

| Heating System | Max Temperature, Heating/Cooling Rates, Zones | Up to High Temperatures, Multiple Zones |

| Gas Delivery | Number of Lines, MFCs | Custom Gas Sticks, Precise Control |

| Vacuum System | Ultimate Vacuum Level | Low to High Vacuum, Pump Combinations |

| Physical Configuration | Footprint, Integration | Benchtop, Freestanding, Glovebox Integration |

Ready to enhance your lab's capabilities with a custom CVD furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Tube Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to discuss how we can optimize your process!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What environments does a PECVD system provide for silicon nanowires? Optimize Growth with Precise Thermal Control

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- What are the technical advantages of using a CVD system? Optimize Carbon Nanotube Growth for Thermal Conductivity

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK