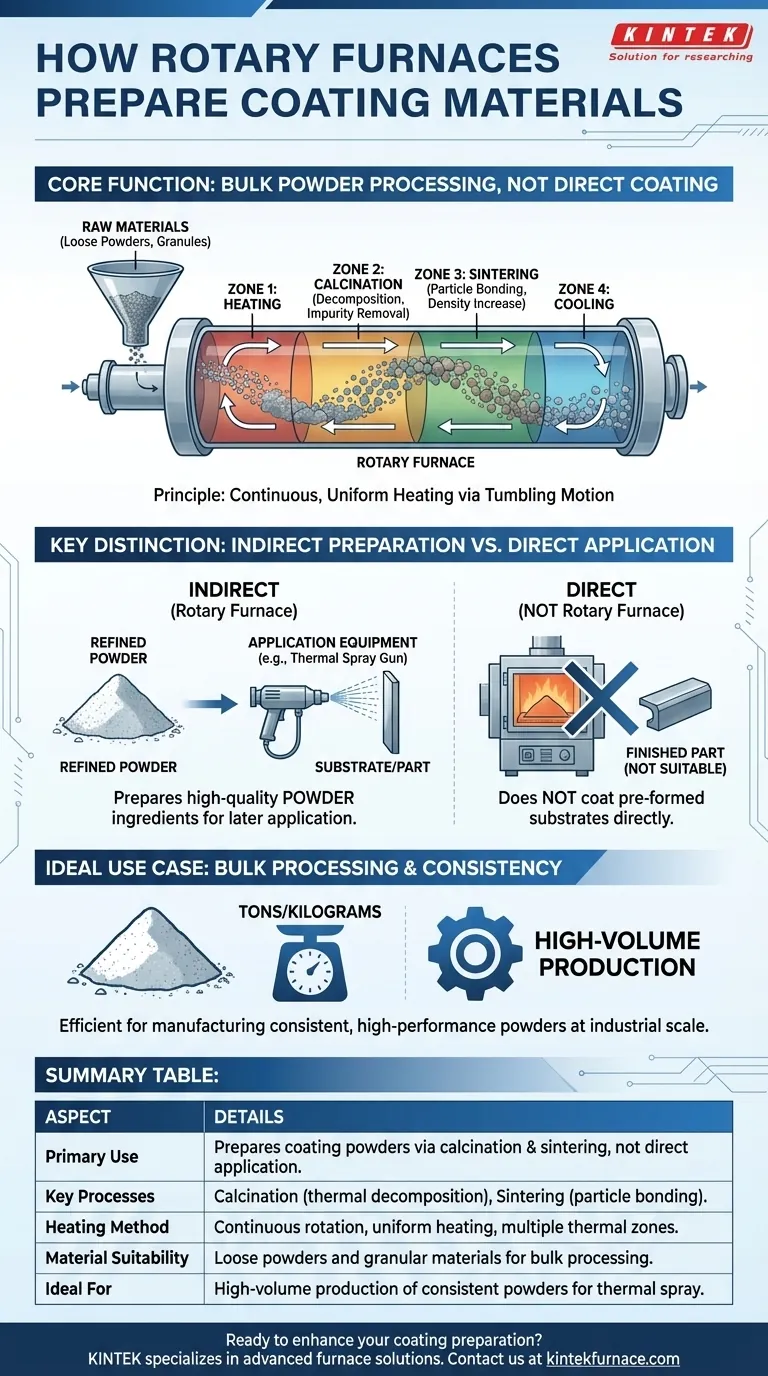

At their core, rotary furnaces are used in coating preparation not to apply the coating itself, but to create and refine the high-performance powders and granular materials that serve as the foundation for advanced coatings. By subjecting these loose materials to precisely controlled, uniform heat, these furnaces perform critical thermal processes like calcination and sintering, which are essential for developing the desired chemical composition, purity, and physical properties of the final coating material.

The most critical distinction to understand is that rotary furnaces prepare the ingredients for a coating, they do not bake the final coated product. Their primary role is the bulk thermal processing of powders that will later be applied to substrates using other methods like thermal spray.

The Principle: Processing Loose Materials at Scale

A rotary furnace's design is fundamentally centered on the continuous, uniform heating of loose, flowing materials. This makes it uniquely suited for preparing the raw materials for coatings, rather than coating finished parts.

Continuous Motion for Uniform Heating

The furnace is a cylindrical tube that rotates slowly, tumbling the material within it. This constant motion ensures every particle is exposed to the same heat conditions, eliminating hot spots and guaranteeing a homogenous final product.

This level of uniformity is critical for producing coating powders with consistent performance characteristics.

Multiple, Precise Thermal Zones

Modern rotary furnaces are not single-temperature ovens. They feature multiple, independently controlled heating zones along the length of the tube.

This allows for a precise thermal profile where material can be gently heated, held at a peak temperature for a specific duration (dwell time), and then cooled at a controlled rate, all in one continuous process.

Key Processes for Powder Preparation

Two primary thermal processes conducted in rotary furnaces are vital for creating coating materials:

- Calcination: This is a thermal decomposition process. It's used to break down raw chemical compounds, remove impurities like water or carbonates, and trigger chemical reactions to form a new, stable compound—the basis for a ceramic or metallic coating powder.

- Sintering: This process uses heat to bond particles together without melting them entirely. For coating powders, controlled sintering can increase particle density and strength, which directly impacts the durability and quality of the final applied coating.

Understanding the Key Distinction: Indirect vs. Direct Application

The most common point of confusion is how a rotary furnace fits into the overall coating workflow. Understanding its limitations is as important as knowing its strengths.

An Indirect, Preparatory Step

Using a rotary furnace is an indirect part of the coating process. The furnace produces a high-quality powder. That powder is then loaded into separate equipment—such as a plasma spray gun or a high-velocity oxygen fuel (HVOF) system—to be applied to the final component.

Not for Coating Pre-Formed Substrates

You would not place a finished machine part or a large optical mirror inside a rotary furnace to coat it. The tumbling action would damage the part, and the process is not designed to apply a uniform layer to a solid, stationary object.

For direct coating of substrates, processes like Chemical Vapor Deposition (CVD) in a static furnace, Physical Vapor Deposition (PVD), or electroplating are the appropriate technologies.

Best Suited for Bulk Processing

The strength of a rotary furnace lies in its ability to run continuously, processing large volumes of material efficiently. It is an industrial-scale tool ideal for manufacturing kilograms or tons of coating powder, not for lab-scale experiments on a few grams.

Making the Right Choice for Your Goal

To select the right thermal process, you must be clear about your objective within the materials engineering workflow.

- If your primary focus is producing consistent, high-volume coating powder: A rotary furnace is the definitive tool for calcining and sintering bulk raw materials for use in thermal spray applications.

- If your primary focus is developing a novel coating material: The precise, repeatable thermal control of a rotary furnace makes it an excellent tool for optimizing the properties of a new powder formulation at a pilot scale.

- If your primary focus is applying a thin, uniform film onto a finished component: You should investigate direct application methods like CVD, PVD, or plating, as a rotary furnace is not suited for this task.

Ultimately, a rotary furnace empowers you to control the fundamental chemistry and structure of your coating materials before they ever touch a substrate.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | Prepares coating powders via calcination and sintering, not direct coating application. |

| Key Processes | Calcination (thermal decomposition), Sintering (particle bonding). |

| Heating Method | Continuous rotation for uniform heating across multiple thermal zones. |

| Material Suitability | Loose powders and granular materials for bulk processing. |

| Ideal For | High-volume production of consistent powders for thermal spray coatings. |

Ready to enhance your coating preparation with precision? KINTEK specializes in advanced high-temperature furnace solutions, including Rotary Furnaces, designed for bulk processing of powders. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Our product line—featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—ensures reliable performance for industries requiring durable coatings. Contact us today to discuss how our solutions can optimize your thermal processes and boost efficiency!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing