In short, porcelain furnaces are indispensable tools for manufacturing both heat-resistant refractory materials and highly specialized materials like advanced ceramics and battery components. They achieve this by providing the precisely controlled, high-temperature environments required to fire, sinter, or chemically alter raw materials into a final, high-performance product.

The term "porcelain furnace" often serves as a general category for a range of high-temperature furnaces. Their true value in modern materials science lies not just in reaching high temperatures, but in their ability to precisely control the atmosphere—from a pure vacuum to a specific gas—to dictate the final properties of the material being created.

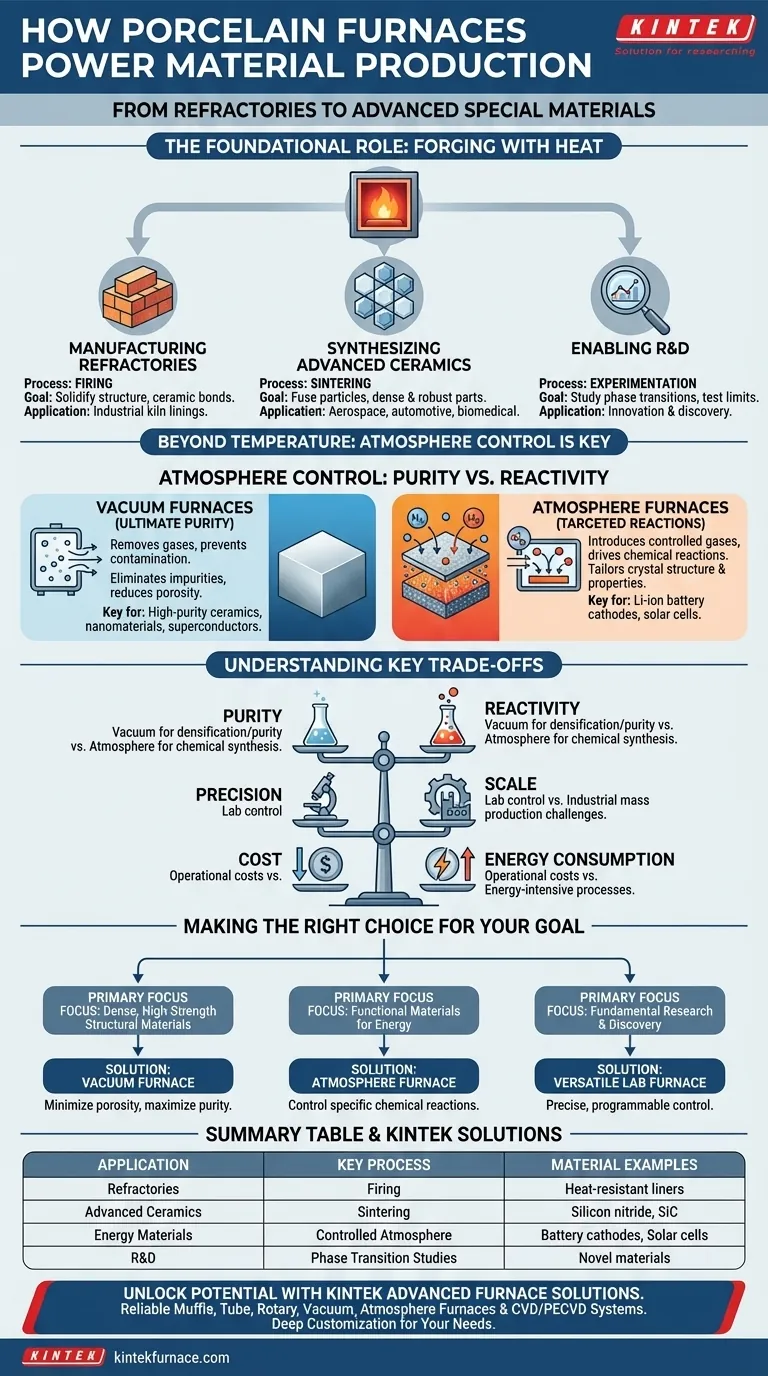

The Foundational Role: Forging Materials with Heat

At its core, a high-temperature furnace is a tool for initiating physical and chemical changes that are only possible with intense thermal energy. This fundamental capability is applied across a wide range of material production.

Manufacturing Refractories

Refractories are materials designed to withstand extreme temperatures without degrading, making them essential for lining industrial kilns, reactors, and furnaces. A porcelain furnace is used to fire these materials, solidifying their structure and creating the ceramic bonds that give them their exceptional thermal stability.

Synthesizing Advanced Ceramics

Materials like silicon nitride (Si₃N₄) and silicon carbide (SiC) are used in demanding aerospace, automotive, and biomedical applications. Furnaces enable their production through a process called sintering, which fuses fine particles together under heat to create a dense, non-porous, and mechanically robust final part.

Enabling Research and Development

For universities and research institutes, these furnaces are the workhorses of materials science. They allow researchers to experiment with new compositions, study phase transitions at high temperatures, and test the performance limits of novel materials, driving innovation across industries.

Beyond Temperature: The Importance of Atmosphere Control

The most significant advancements in material production come from specialized furnaces that do more than just generate heat. Controlling the gaseous environment inside the furnace is critical for creating materials with specific, engineered properties.

Vacuum Furnaces for Ultimate Purity

A vacuum furnace removes air and other gases from the chamber during heating. This prevents contamination and unwanted oxidation, which is crucial for producing high-purity materials like advanced ceramics, nanomaterials, and superconductors.

By eliminating impurities and gas pockets, vacuum sintering helps materials achieve near-theoretical density. This reduces porosity, which dramatically increases a material's strength, hardness, and thermal resistance.

Atmosphere Furnaces for Targeted Reactions

In contrast to a vacuum, an atmosphere furnace allows for the introduction of specific, controlled gases. This is used to intentionally drive desired chemical reactions.

For example, in the production of lithium-ion battery cathodes, a specific atmosphere can help form the ideal crystal structure for high electrochemical performance. Similarly, in solar cell manufacturing, processes like doping silicon wafers are performed in a controlled atmosphere to improve their photoelectric efficiency.

Understanding the Key Trade-offs

Choosing the right furnace technology involves balancing competing priorities. The decision directly impacts the properties of the final material and the efficiency of the process.

Purity vs. Reactivity

The primary trade-off is between a vacuum and a controlled atmosphere. A vacuum environment is ideal when the goal is densification and purity, preventing any interaction with outside elements. An atmosphere environment is chosen when a specific chemical reaction is a necessary part of the material's synthesis.

Precision vs. Scale

Laboratory-scale furnaces offer exceptional control over temperature gradients and atmospheric conditions, which is perfect for research and developing new materials. However, translating these precise conditions to large, industrial-scale furnaces for mass production can be a significant engineering challenge, often requiring compromises in uniformity.

Cost and Energy Consumption

High-temperature furnaces are energy-intensive. Processes requiring extreme temperatures, long durations, or complex atmosphere control come with significant operational costs. This economic reality is a critical factor in both research and industrial production.

Making the Right Choice for Your Goal

The type of furnace process you use is determined entirely by the desired characteristics of your final material.

- If your primary focus is creating dense, high-strength structural materials: A vacuum furnace is essential for minimizing porosity and maximizing purity to achieve superior mechanical properties.

- If your primary focus is synthesizing functional materials for energy applications: An atmosphere furnace is necessary to control the specific chemical reactions that create the material's active properties.

- If your primary focus is fundamental research and material discovery: A versatile lab furnace with precise, programmable control over both temperature and atmosphere is the key to exploring new possibilities.

Ultimately, these furnaces are the critical instruments that allow us to transform basic elements into the advanced materials that define modern technology.

Summary Table:

| Application | Key Process | Material Examples |

|---|---|---|

| Refractories | Firing | Heat-resistant liners |

| Advanced Ceramics | Sintering | Silicon nitride, Silicon carbide |

| Energy Materials | Controlled atmosphere reactions | Lithium-ion battery cathodes, Solar cells |

| Research & Development | Phase transition studies | Novel materials for aerospace, biomedical |

Unlock the full potential of your material production with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your projects with tailored furnace technology!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing