Yes, horizontal tube furnaces are frequently designed to support controlled atmosphere experiments. This is a core capability that enables a wide range of processes requiring specific environmental conditions, most commonly by creating an inert gas environment or a vacuum. This feature is critical for protecting materials from oxidation or contamination during high-temperature processing.

The ability to control the atmosphere is a fundamental feature of modern horizontal tube furnaces. However, the success of your experiment hinges not just on having this capability, but on understanding the practical limitations of temperature uniformity and gas sealing inherent in the design.

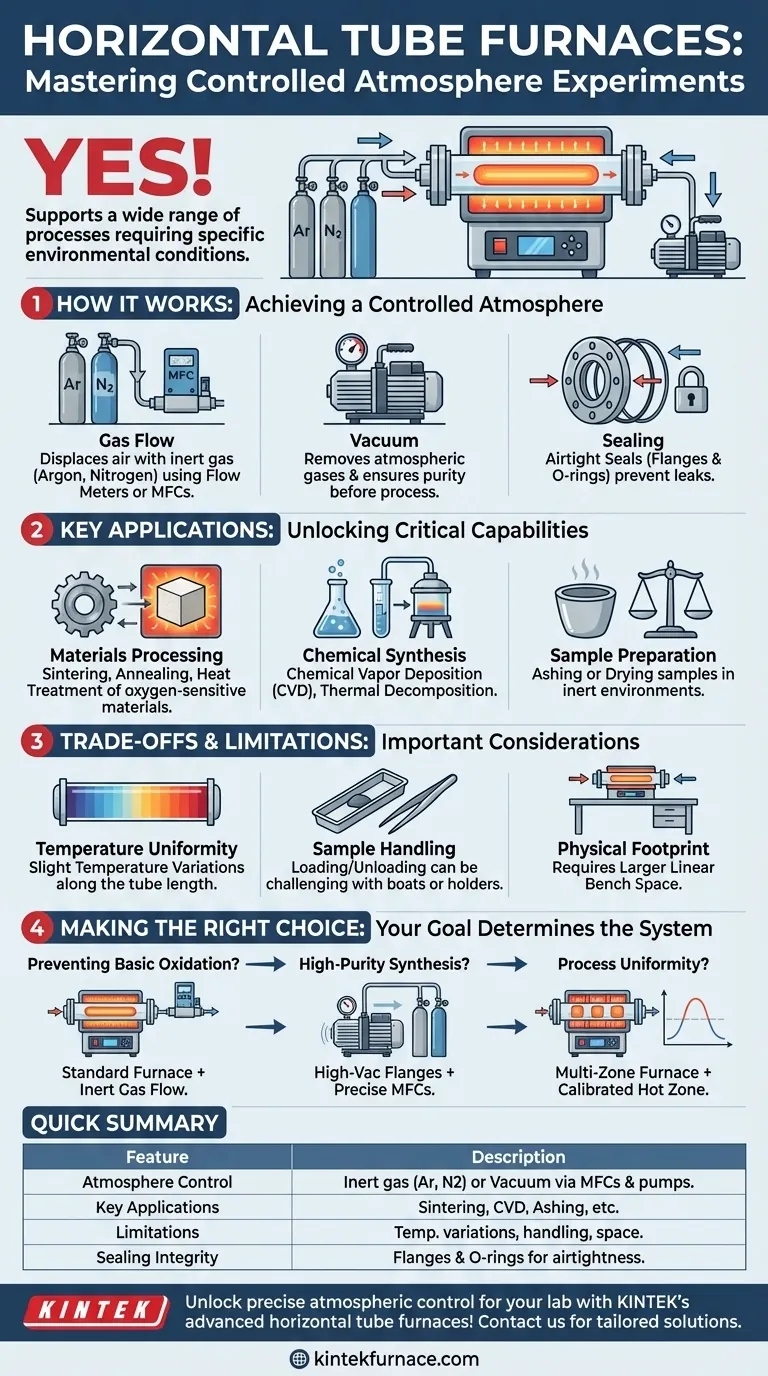

How Horizontal Tube Furnaces Achieve a Controlled Atmosphere

A controlled atmosphere is achieved by displacing the ambient air (primarily oxygen and nitrogen) inside the furnace's process tube and replacing it with a desired gas or by creating a vacuum. This is managed through a few key systems.

The Role of Gas Flow Systems

To create an inert environment, a gas like argon or nitrogen is introduced into the process tube. This gas flow purges the oxygen, preventing unwanted chemical reactions like oxidation at high temperatures. The flow rate is managed by flow meters or more precise mass flow controllers (MFCs) to ensure a consistent and stable atmosphere.

Achieving a Vacuum Environment

Many systems can be connected to a vacuum pump. This allows for the removal of atmospheric gases from the sealed tube before heating or before backfilling with a specific process gas. Operating under a vacuum is essential for certain deposition processes and for ensuring the highest purity in an inert gas environment.

The Importance of Sealing and Integrity

The entire system's effectiveness depends on the quality of the seals at the ends of the tube. These are typically achieved with flanges and O-rings that create an airtight connection. A poor seal will allow ambient air to leak into the tube, compromising the integrity of the controlled atmosphere.

Key Applications Enabled by Atmospheric Control

Controlling the furnace environment unlocks critical capabilities for research and production across numerous fields.

Materials Processing

Atmospheric control is essential for processes like sintering, annealing, and heat treatment of oxygen-sensitive metals, ceramics, and alloys. It prevents the formation of oxide layers that can degrade the material's properties.

Chemical Synthesis and Research

Processes like Chemical Vapor Deposition (CVD) and thermal decomposition rely on a precisely controlled atmosphere. In these reactions, specific precursor gases are introduced into the furnace to react and form a new material, requiring an environment free of contaminants.

Sample Preparation

For materials analysis, samples may need to be prepared by ashing or drying at high temperatures. Performing this in an inert atmosphere ensures that the sample's fundamental composition is not altered by oxidation before characterization.

Understanding the Trade-offs and Limitations

While powerful, horizontal tube furnaces have practical constraints that you must consider for successful operation.

Temperature Uniformity

The horizontal orientation can lead to slight temperature variations along the length of the furnace's heated zone. This means a long sample may not experience a perfectly uniform temperature, requiring careful placement of the sample in the calibrated "hot zone" or optimization of the temperature profile.

Sample Handling and Access

Loading and unloading samples, especially delicate or powdered ones, can be more challenging in a horizontal tube compared to a top-loading vertical furnace. Samples must be placed in boats or holders that can be pushed into and pulled out of the tube.

Physical Footprint

By their nature, horizontal tube furnaces require a larger amount of linear bench space compared to their vertical counterparts. This can be a significant factor in a crowded laboratory environment.

Making the Right Choice for Your Experiment

Your specific goal will determine which aspects of the furnace's performance are most critical.

- If your primary focus is preventing basic oxidation (e.g., annealing steel): A standard horizontal tube furnace with a reliable inert gas flow system is an excellent and cost-effective choice.

- If your primary focus is high-purity synthesis (e.g., growing crystals or CVD): You must prioritize a system with high-integrity vacuum flanges and precise mass flow controllers to ensure atmospheric purity.

- If your primary focus is process uniformity for long samples: Pay close attention to the furnace's specified uniform temperature zone and consider a multi-zone furnace for more active temperature control.

By understanding these capabilities and limitations, you can confidently select and operate a horizontal tube furnace to achieve precise atmospheric control for your critical experiments.

Summary Table:

| Feature | Description |

|---|---|

| Atmosphere Control | Achieved via inert gas flow (e.g., argon, nitrogen) or vacuum systems, using mass flow controllers for precision. |

| Key Applications | Sintering, annealing, CVD, thermal decomposition, and sample preparation in inert environments. |

| Limitations | Temperature variations along the tube, challenging sample handling, and larger bench space requirements. |

| Sealing Integrity | Relies on flanges and O-rings to maintain airtight conditions and prevent contamination. |

Unlock precise atmospheric control for your lab with KINTEK's advanced horizontal tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to enhance your material processing efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency