Yes, you can and should fire multiple restorations simultaneously in a dental ceramic furnace. Modern furnaces are engineered specifically for this purpose to maximize laboratory efficiency. However, success is not automatic; it depends entirely on a precise and disciplined approach to placement and an understanding of thermal dynamics within the firing chamber.

Firing multiple restorations is a standard practice for efficiency, but this efficiency is lost if the process compromises quality. The core challenge is ensuring every unit receives uniform heat, as improper placement can lead to inconsistent results, remakes, and financial loss.

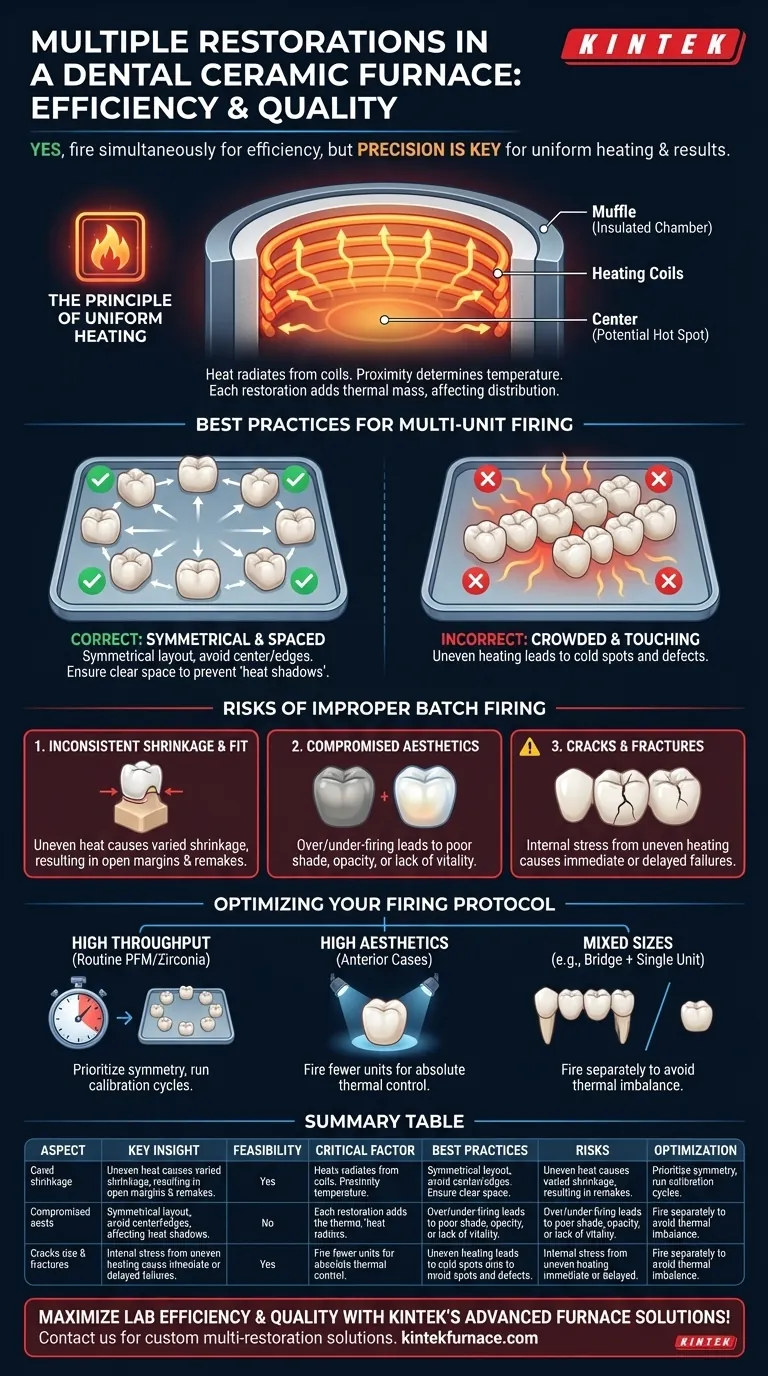

The Principle of Uniform Heating

A ceramic furnace is more than just an oven; it's a precision instrument. Understanding how heat behaves inside the chamber is the key to predictable multi-unit firing.

Why Heat Distribution is Critical

Ceramic materials undergo critical physical and chemical changes—like sintering and vitrification—at exact temperatures. If one part of a restoration is even slightly hotter or cooler than another, it matures unevenly. This creates internal stress, compromises aesthetics, and can ruin the fit.

The Role of the Furnace Muffle

The muffle is the insulated heating chamber containing the heating coils. Heat radiates from these coils toward the center. Any object's temperature is determined by its proximity to these coils, the thermocouple, and other restorations.

The Impact of Thermal Mass

Each restoration adds to the thermal mass inside the furnace. Firing a full tray requires more energy and time to reach the target temperature than firing a single unit. The furnace must work to heat this larger mass uniformly, and a crowded tray can create cold spots.

Best Practices for Multi-Unit Firing

Simply placing restorations on the tray is insufficient. Strategic placement is required to ensure every unit experiences the programmed firing cycle as intended.

The Importance of Symmetrical Placement

Arrange restorations in a symmetrical pattern on the firing tray, ideally in a circle around the center. Avoid placing any unit directly in the center (often a hot spot) or too close to the muffle walls. This promotes an even "view" of the heating elements for each restoration.

Maintaining Adequate Spacing

Ensure there is clear space around each restoration. This is not just to prevent them from touching. Proper spacing allows radiant heat to fully envelop each unit, preventing one restoration from casting a "heat shadow" on its neighbor and causing a cold spot.

Stabilizing the Restorations

Use high-quality firing pegs and, if necessary, refractory paste to keep each unit stable. Restorations can shift slightly when the vacuum engages or during heating. Any contact between units will create a significant flaw and likely ruin both pieces.

Understanding the Trade-offs and Risks

When batch firing is done incorrectly, the consequences directly impact the quality of your work and the profitability of your lab.

Risk 1: Inconsistent Shrinkage and Fit

The most common failure is a compromised fit. If a crown's margin fires at a different temperature than its occlusal surface, the resulting uneven shrinkage can lead to open margins that require a complete remake.

Risk 2: Compromised Aesthetics

Uneven heating directly affects the final shade and translucency. Overheated areas can appear overly bright, washed out, or "milky." Under-fired areas may look gray, dull, and lacking in vitality. For anterior cases, this inconsistency is unacceptable.

Risk 3: Cracks and Fractures

Internal stresses created by uneven heating are a primary cause of fractures. These might appear immediately upon cooling or, more dangerously, as a delayed failure after the restoration has been seated in the patient's mouth.

Optimizing Your Firing Protocol

Your firing strategy should align with the specific demands of the case. A one-size-fits-all approach is rarely optimal.

- If your primary focus is maximum throughput for routine PFM or monolithic zirconia cases: Prioritize symmetrical tray layouts and run calibration cycles with a full load to ensure your programs are accurate for batch firing.

- If your primary focus is high-end anterior aesthetics: Fire fewer, more critical restorations at once to guarantee absolute control and thermal uniformity for each unit.

- If you are firing restorations of vastly different sizes (e.g., a single molar and a 4-unit bridge): Fire them separately, as the larger thermal mass of the bridge will dominate the firing cycle and compromise the firing of the smaller unit.

By treating the furnace as a precision tool, you can consistently leverage batch firing to increase your lab's efficiency without sacrificing quality.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Feasibility | Yes, modern furnaces support multi-unit firing for efficiency. |

| Critical Factor | Uniform heat distribution is essential to avoid defects. |

| Best Practices | Symmetrical placement, adequate spacing, and stabilization. |

| Risks | Inconsistent fit, aesthetics, and fractures if done improperly. |

| Optimization | Adjust protocols based on case type (e.g., high-throughput vs. aesthetics). |

Maximize your dental lab's efficiency and quality with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as multi-restoration firing. Contact us today to discuss how we can enhance your workflow and deliver reliable results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures