You’ve run the same thermal process three times. The first run was perfect. The second produced a brittle, useless sample. The third was somewhere in between. You've checked the gas flow, calibrated the scales, and used materials from the same batch. Yet, the results are wildly unpredictable. Weeks of work are on the line, and you're left staring at the furnace, wondering what invisible force is sabotaging your experiment.

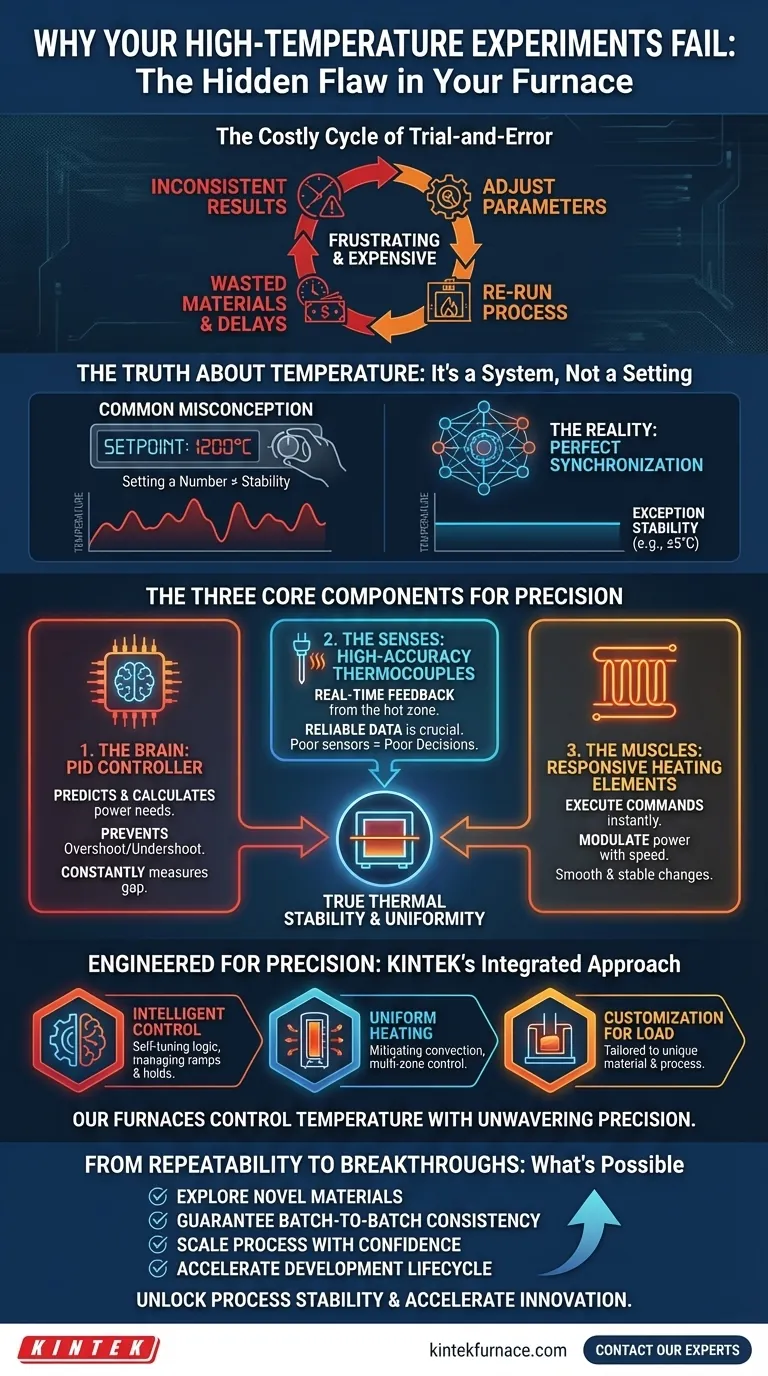

The Costly Cycle of Trial-and-Error

This scenario is frustratingly common in labs and production facilities worldwide. When faced with inconsistent outcomes in processes like sintering, annealing, or crystal growth, the natural response is to tweak the parameters. Engineers and researchers find themselves caught in a loop of trial-and-error:

- Adjusting the temperature ramp rate up or down.

- Extending the “soak” time, hoping for better uniformity.

- Repositioning the sample inside the chamber.

- Questioning the purity of the raw materials.

While well-intentioned, these adjustments rarely solve the underlying issue. This isn't just an academic problem; it has direct financial consequences. Each failed run translates to wasted high-value materials, project delays that postpone product launches, and a critical loss of confidence in your R&D or manufacturing process.

The Truth About Temperature: It's a System, Not a Setting

The root of the problem isn't in your process parameters; it's in the furnace's fundamental ability to execute them. Many assume that setting a temperature to "1200°C" means the furnace will hold that temperature perfectly. The reality is that true thermal stability is not a single feature—it's the result of a perfectly synchronized system working in constant harmony.

The "common solutions" from the previous section fail because they are like telling a clumsy driver to simply "turn the wheel more." They don't address the poor coordination that is the real cause of the problem. True precision relies on the seamless integration of three core components:

1. The Brain: The PID Controller

A sophisticated Proportional-Integral-Derivative (PID) controller does more than just switch the heat on and off. It constantly measures the gap between your setpoint and the real temperature, predicts where the temperature is heading, and calculates the precise amount of power needed to counteract any deviation before it happens. Without an intelligent brain, the furnace will constantly overshoot and undershoot your target.

2. The Senses: High-Accuracy Thermocouples

The controller is completely blind without reliable data. Strategically placed thermocouple sensors act as the system's eyes and ears, providing real-time feedback from the heart of the hot zone. If these sensors are inaccurate or poorly positioned, the brain receives bad information and makes poor decisions, regardless of how advanced it is.

3. The Muscles: Responsive Electric Heating Elements

Finally, the heating elements must be able to execute the controller's commands instantly and precisely. Clean electric heating elements can be modulated with incredible speed, allowing for the smooth, stable temperature changes required for sensitive materials. A sluggish or imprecise heat source cannot keep up with the brain's commands.

When this trio works in perfect unison, the furnace can maintain exceptional stability (e.g., ±5℃) and uniformity. When any one part is out of sync, inconsistency and failure are the inevitable results.

Engineered for Precision: The Anatomy of a Reliable Furnace

To overcome this fundamental challenge, you don't need to become a control systems expert. You need a tool that was built by them. A truly precise furnace is not just a collection of parts; it is an integrated system where every component is designed and manufactured to work together flawlessly.

This is the philosophy behind KINTEK’s advanced furnace solutions. Because we leverage in-house R&D and manufacturing, we have granular control over how these critical systems are integrated.

- Intelligent Control: Our PID systems, often equipped with self-tuning logic, are meticulously matched to the furnace's thermal properties, ensuring they can intelligently manage everything from rapid ramps to long, stable holds.

- Uniform Heating: We don't just place heating elements; we engineer the heating chamber. Our vertical tube furnace designs, for example, are inherently better at mitigating convection currents, providing a more uniform thermal environment for your samples. For complex applications, our multi-zone furnaces provide independent control over different sections, allowing you to create perfect uniformity or precise temperature gradients on demand.

- Customization for Your Load: Every sample (or "thermal load") behaves differently. Our deep customization capability means we can engineer a furnace solution specifically for your unique material and process, ensuring the control system is perfectly optimized to deliver repeatable results every single time.

Our furnaces are not just designed to reach a temperature; they are engineered to control it with unwavering precision.

From Repeatability to Breakthroughs: What's Possible with True Thermal Control

When temperature ceases to be a random variable, it becomes your most powerful tool. Once you can trust your furnace to deliver the exact same thermal profile run after run, your focus shifts from damage control to genuine innovation.

Suddenly, you can:

- Explore Novel Materials that require extremely precise thermal processing windows.

- Guarantee Batch-to-Batch Consistency for critical components, improving product quality and reliability.

- Scale Your Process from R&D to production with confidence, knowing the results are repeatable.

- Accelerate Your Development Lifecycle by eliminating weeks of frustrating trial-and-error.

Your research and production are too important to be derailed by guesswork. True thermal control isn't just about hitting a number on a display; it's about unlocking process stability, accelerating innovation, and delivering reliable products. If you're ready to move past the cycle of inconsistent results, let's discuss the specific demands of your project. Our team is here to help you design a system that delivers the control and repeatability your work deserves. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

Related Articles

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity