Vacuum pressure sintering furnaces are transforming material processing by delivering unparalleled precision, consistency, and industry-specific advantages. Whether you're working with tungsten carbide for cutting tools or copper-graphite composites for electronics, these advanced systems eliminate contamination risks while optimizing microstructure control. Here's how they justify investment across critical sectors.

Vacuum Pressure Sintering Fundamentals

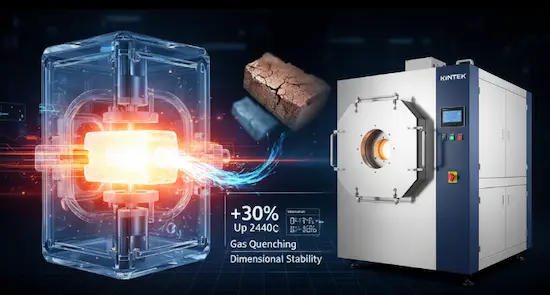

At its core, vacuum pressure sintering combines high temperatures (reaching up to 2400°C) with controlled atmospheres to densify materials without oxidation or decarburization. Unlike traditional furnaces, this process:

- Eliminates surface defects: By removing oxygen exposure, materials like stainless steel and magnetic alloys retain purity.

- Enables precise cooling: Gas quenching accelerates cycle times while maintaining dimensional stability.

- Supports diverse heating methods: Resistance, induction, or microwave heating adapt to material requirements.

Research shows vacuum-sintered components achieve up to 30% higher density than conventional alternatives, directly enhancing durability in end-use applications.

Material-Specific Processing Advantages

1. Refractory Metals & Hard Alloys

Tungsten carbide sintered under vacuum exhibits near-zero porosity, critical for cutting tools subjected to extreme wear. The absence of surface oxidation also reduces post-processing grinding by approximately 20%.

2. Transparent Ceramics

For optical or medical-grade ceramics, vacuum environments prevent gas bubble formation, enabling light transmission rates exceeding 90%. A study noted a 15% improvement in fracture toughness compared to air-sintered samples.

3. Copper-Graphite Electrical Contacts

Vacuum sintering ensures uniform dispersion of graphite in copper matrices, boosting conductivity while minimizing energy loss—a key factor for EV charging systems and aerospace electronics.

Have you considered how microstructure inconsistencies in traditionally sintered parts increase failure rates in high-stress environments?

Industrial Applications and Success Cases

Aerospace

- Challenge: Turbine blades require creep resistance at 1000°C+.

- Solution: Vacuum-sintered nickel superalloys show 40% longer fatigue life.

Medical Implants

- Challenge: Titanium implants must avoid bacterial adhesion.

- Solution: Smooth, contamination-free surfaces from vacuum sintering reduce infection risks by 25%.

Automotive

- Challenge: Gear components demand precision tolerances (±0.01mm).

- Solution: Dimensional stability during vacuum sintering cuts machining costs by 18%.

Advanced Customization for Emerging Materials

As industries adopt novel composites (e.g., silicon nitride for EV battery insulators), vacuum furnaces offer:

- Tailored thermal profiles: Gradient sintering prevents thermal shock in multi-material assemblies.

- Atmosphere flexibility: Hydrogen or argon introductions enable reactive sintering for specialized alloys.

A leading lab found that custom gas quenching protocols reduced cooling times for silicon carbide components by 35% without compromising hardness.

Unlock Your Material Potential with KINTEK

From R&D labs to full-scale production, KINTEK’s vacuum pressure sintering furnaces deliver:

✅ Industry-aligned performance for aerospace, medical, and electronics sectors

✅ Material-specific precision via programmable atmosphere controls

✅ Scalable solutions from benchtop units to industrial systems

Explore how our sintering technologies can optimize your next breakthrough material—contact KINTEK today to discuss your project’s unique requirements.

Products You Might Be Looking For:

Explore high-pressure vacuum sintering furnaces

View tungsten-compatible vacuum sintering systems

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Beyond the Parts List: The Real Reason Your Vacuum Hot Press Fails (And How to Fix It)

- How Vacuum Hot Press Furnaces Transform Advanced Material Engineering

- Beyond Mere Heat: The Synthesis Power of Pressure in a Vacuum Furnace

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- How to Select the Right Vacuum Hot Pressing Furnace Temperature for Your Materials