At its core, the porcelain furnace is a critical tool because it provides the precise, high-temperature environment needed to transform raw materials into durable, highly specialized components. Its applications span numerous fields, from crafting dental restorations and advanced ceramics to metallurgy and scientific research, making it indispensable for creating products that require specific physical and aesthetic properties.

A porcelain furnace's true value lies not just in its ability to generate heat, but in its capacity to control the heating and cooling process with extreme precision. This control is what allows professionals to predictably and repeatedly create materials with superior strength, exact dimensions, and desired aesthetics.

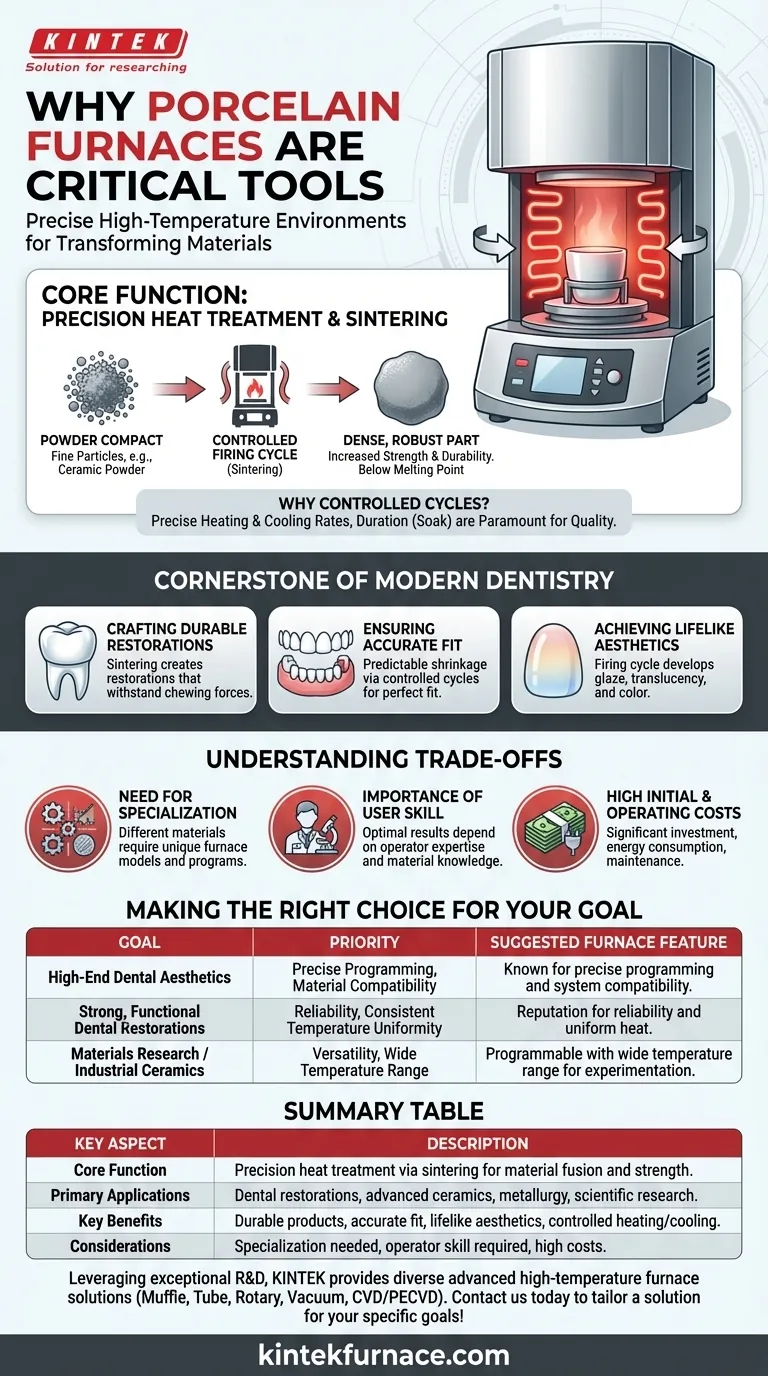

The Core Function: Precision Heat Treatment

A porcelain furnace is far more than a simple oven. Its purpose is to execute highly specific thermal programs that fundamentally change the structure of materials.

What is Sintering?

The primary process is sintering, where fine particles (like ceramic powders) are heated until they fuse into a solid, dense mass. This is done at a temperature below the material's melting point.

This process dramatically increases the material's strength and durability, turning a fragile powder compact into a robust, functional part.

Why Controlled Cycles are Paramount

The quality of the final product depends entirely on the firing cycle—the precise rate of temperature increase, the duration the temperature is held (the "soak"), and the rate of cooling.

An incorrect cycle can result in a weak, porous, or warped product. Different materials require unique cycles to achieve their optimal properties, making the furnace's programmability a crucial feature.

A Cornerstone of Modern Dentistry

The most visible application of the porcelain furnace is in the dental lab, where it is essential for creating crowns, bridges, and veneers.

Crafting Durable Restorations

Dental porcelain starts as a delicate powder. The furnace sinters these particles to create a restoration that can withstand the immense forces of chewing for years.

Without this controlled heat treatment, dental prosthetics would be too fragile for clinical use.

Ensuring Accurate Fit and Function

The sintering process also causes the porcelain to shrink. A high-quality furnace and a properly programmed cycle ensure this shrinkage is predictable and uniform.

This precision is vital for creating a restoration that fits the patient's tooth perfectly, ensuring comfort and proper oral function.

Achieving Lifelike Aesthetics

The firing cycle is also responsible for developing the final appearance of a dental restoration. It creates the glass-like surface (glaze) and develops the material's translucency and color.

This allows a skilled technician to create a restoration that is virtually indistinguishable from a natural tooth.

Understanding the Trade-offs

While indispensable, the porcelain furnace is a specialized piece of equipment with specific operational requirements and limitations.

The Need for Specialization

Not all furnaces are the same. Different models are designed for specific types of ceramic or metal alloys, each with unique temperature requirements.

Using the wrong furnace or program for a given material will lead to a failed product, wasting time and expensive materials.

The Importance of User Skill

The furnace is a tool, and its output is only as good as the operator's expertise. A technician must understand material science and the nuances of firing cycles to achieve optimal results.

Achieving consistent, high-quality outcomes requires significant training and experience.

High Initial and Operating Costs

These are high-precision instruments, representing a significant capital investment. They also consume considerable energy and require regular maintenance and calibration to maintain their accuracy.

This cost is a major factor for labs and manufacturing facilities, making the furnace a central piece of their financial and operational planning.

Making the Right Choice for Your Goal

The selection and use of a porcelain furnace should be directly tied to your specific objective.

- If your primary focus is high-end dental aesthetics: Invest in a furnace known for its precise programming and compatibility with the specific porcelain systems you use to ensure lifelike results.

- If your primary focus is producing strong, functional dental restorations: Prioritize a furnace with a reputation for reliability and consistent temperature uniformity to guarantee predictable strength and fit.

- If your primary focus is materials research or industrial ceramics: Select a versatile, programmable furnace with a wide temperature range to accommodate experimentation with various materials and sintering cycles.

Ultimately, the porcelain furnace is a powerful enabling technology, allowing us to engineer and perfect materials for the most demanding applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Precision heat treatment via sintering for material fusion and strength |

| Primary Applications | Dental restorations, advanced ceramics, metallurgy, scientific research |

| Key Benefits | Durable products, accurate fit, lifelike aesthetics, controlled heating/cooling |

| Considerations | Specialization needed, operator skill required, high costs |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in dental labs, ceramics production, or materials research, our furnaces deliver the precision and reliability you need for superior outcomes. Contact us today to discuss how we can tailor a solution for your specific goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency