In the world of industrial equipment, a supplier's reputation is your single most reliable indicator of an asset's future performance and total cost. When purchasing an induction melting furnace, reputation is not just about a smooth sales process; it is a direct reflection of the equipment's engineering quality, its long-term reliability in a demanding production environment, and the quality of the support you will receive when—not if—you need it.

An induction furnace is not a one-time purchase; it is the start of a multi-decade relationship with a technical partner. A supplier's reputation is the most accurate predictor of that partner's ability to ensure your operational uptime, safety, and long-term profitability.

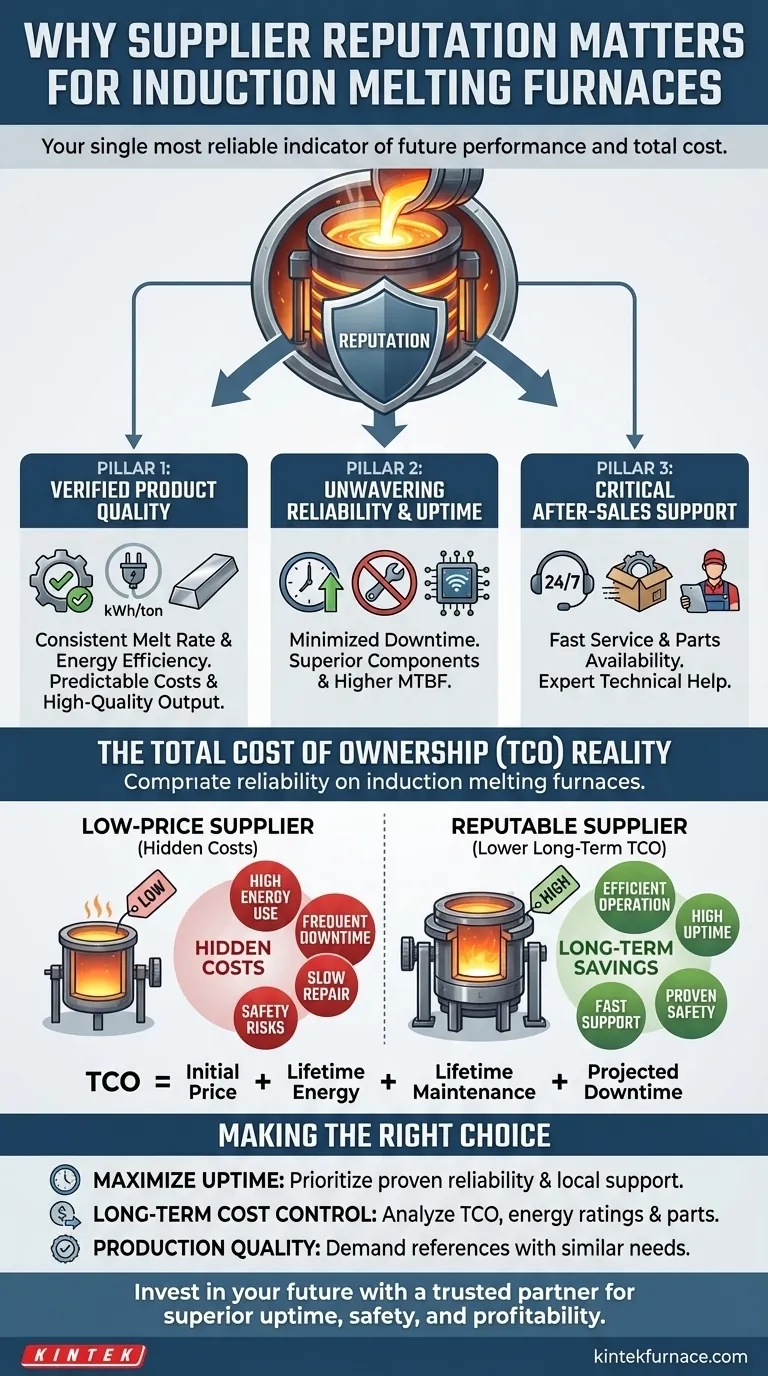

Beyond the Initial Price: The Three Pillars of Reputation

Choosing a furnace supplier based on a low bid without scrutinizing their reputation is a significant financial risk. A supplier’s standing in the industry is built on three core pillars that directly impact your bottom line.

Pillar 1: Verified Product Quality

A strong reputation is earned through consistent, proven performance in the field. This goes far beyond marketing materials.

Verified quality means the furnace you receive will perform to its stated specifications for melt rate, energy consumption (kWh/ton), and metallurgical consistency. Reputable suppliers build their equipment to last, using high-grade materials and robust engineering.

This translates directly to predictable operational costs and consistent, high-quality output from your foundry.

Pillar 2: Unwavering Reliability and Uptime

In any melting operation, downtime is the single greatest cost. An unplanned shutdown can cost thousands or even tens of thousands of dollars per hour in lost production.

A supplier's reputation is a proxy for the furnace's Mean Time Between Failures (MTBF). Esteemed manufacturers are known for building systems with superior components—from the capacitors and IGBTs in the power supply to the integrity of the furnace coil itself.

Investing in a furnace from a supplier known for reliability is a direct investment in maximizing your plant's uptime and productivity.

Pillar 3: The Critical Role of After-Sales Support

Every complex piece of industrial machinery will eventually require service. The difference between a minor hiccup and a catastrophic shutdown is often the speed and competence of your supplier's support team.

A top-tier supplier maintains a robust infrastructure for technical support, spare parts, and field service. Their reputation depends on their ability to diagnose a problem remotely, ship a critical part overnight, and dispatch a qualified technician quickly.

A supplier with a poor reputation may leave you waiting days or weeks for a response or a part, crippling your entire operation.

Understanding the Trade-offs: Price vs. Total Cost of Ownership

The most common mistake in capital equipment procurement is confusing the initial purchase price with the long-term cost of ownership.

The Hidden Costs of a Low-Price Supplier

A furnace with a lower upfront cost often carries significant hidden expenses. These can include:

- Higher energy consumption due to less efficient power supply design.

- Frequent downtime from the use of lower-quality components.

- Longer repair times due to poor parts availability and slow technical support.

- Safety risks from substandard engineering or construction.

These factors can quickly erase any initial savings and result in a far more expensive asset over its lifecycle.

Calculating the Total Cost of Ownership (TCO)

A sophisticated buyer evaluates a furnace based on its TCO, which is a more complete financial model.

TCO = Initial Purchase Price + Lifetime Energy Costs + Lifetime Maintenance & Parts Costs + The Cost of Projected Downtime

When viewed through this lens, the furnace from a highly reputable supplier, even with a higher initial price, almost always represents the superior long-term financial investment.

Making the Right Choice for Your Operation

Evaluating a supplier's reputation is an exercise in risk mitigation. Use these guidelines to frame your decision.

- If your primary focus is maximizing uptime: Prioritize suppliers with a documented history of reliability and a strong, localized after-sales support network.

- If your primary focus is long-term cost control: Analyze the Total Cost of Ownership (TCO), placing heavy emphasis on energy efficiency ratings and the availability of affordable spare parts.

- If your primary focus is production quality: Demand customer references from operations with metallurgical requirements similar to your own and inquire about their experience with melt consistency and temperature control.

Choosing the right supplier is an investment in your company's future operational stability and success.

Summary Table:

| Aspect | Impact of Good Reputation |

|---|---|

| Product Quality | Ensures consistent melt rates, energy efficiency, and metallurgical output |

| Reliability | Maximizes uptime with durable components and fewer failures |

| After-Sales Support | Provides fast technical help, spare parts, and service to minimize downtime |

| Total Cost of Ownership | Lowers long-term costs by reducing energy use, maintenance, and operational losses |

Ready to secure a reliable induction melting furnace tailored to your needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental and production requirements, helping you achieve superior uptime, safety, and profitability. Contact us today to discuss how we can support your operation with dependable, high-performance equipment!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries