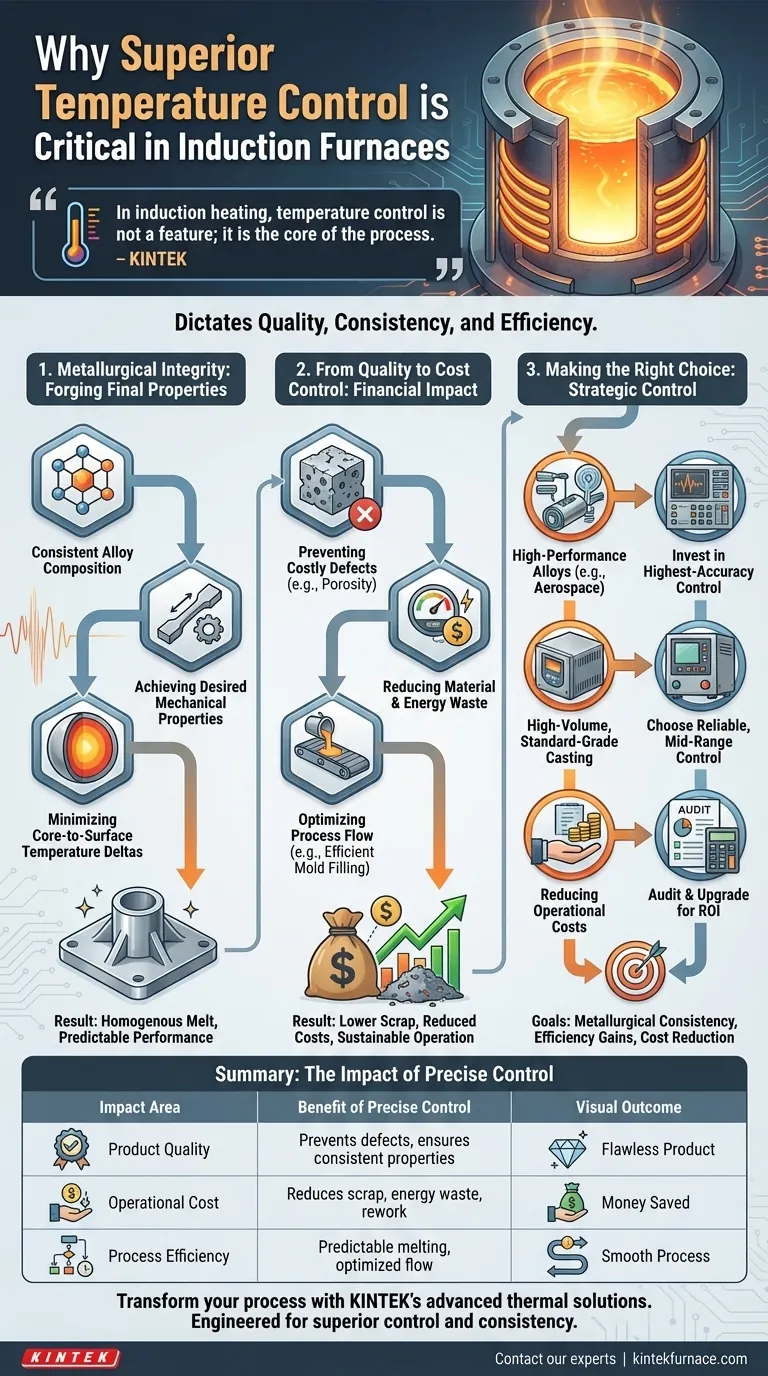

In induction heating, temperature control is not a feature; it is the core of the process. Superior accuracy is critical because it directly dictates the quality and consistency of the final metal product. By maintaining the melt within a precise thermal window, you prevent costly defects, ensure the desired metallurgical properties are achieved, and minimize material and energy waste.

The real value of precise temperature control is not just hitting a target temperature, but maintaining it uniformly and consistently. This transforms the melting process from a variable art into a predictable science, directly impacting material integrity, operational cost, and energy efficiency.

The Link Between Temperature and Metallurgical Integrity

The final properties of a metal or alloy are forged in the furnace. Even minor deviations from the target temperature can have significant and often irreversible consequences on the material's fundamental structure.

Ensuring Consistent Alloy Composition

Precise temperature management is essential for creating high-quality alloys. If the temperature is too high, valuable and volatile alloying elements can burn off, altering the final composition and compromising the material's performance.

Stable temperatures ensure that each batch meets the exact same specification, which is non-negotiable in high-stakes industries like aerospace and medical manufacturing.

Achieving Desired Mechanical Properties

The mechanical properties of a metal—such as hardness, ductility, and tensile strength—are directly linked to its thermal history.

Accurate temperature control ensures the metal solidifies with the correct grain structure and phase distribution, delivering the predictable performance required by engineering specifications.

Minimizing Core-to-Surface Temperature Deltas

Induction furnaces heat from the inside out. Without precise control, a significant temperature difference can develop between the molten core and the cooler surface.

This thermal gradient can introduce internal stresses and lead to defects. Superior control systems minimize this delta, ensuring a homogenous melt and a higher-quality final casting.

From Quality Control to Cost Control

Every degree of temperature inaccuracy represents a potential financial loss. Precise control is a direct lever for improving your operational bottom line through waste reduction and efficiency gains.

Preventing Costly Defects

Many common casting defects, such as porosity and shrinkage, are rooted in improper temperature. A melt that is too hot can absorb excess gas, which is then released during cooling to create voids.

By holding the temperature at the optimal point, you dramatically reduce the rate of scrapped parts and the associated costs of rework or disposal.

Reducing Material and Energy Waste

Overheating the melt doesn't just risk burning off expensive alloys; it's also a direct waste of energy. Every kilowatt-hour used to push the temperature beyond the target is a pure loss.

Precise control systems prevent this temperature "overshoot," leading to lower energy bills and a more efficient, sustainable operation. This also reduces wear on the furnace lining.

Optimizing Process Flow

A consistent, predictable melt temperature enables a smoother downstream process. For example, maintaining the ideal pouring temperature ensures efficient mold filling, which is critical for complex castings and thin-walled parts.

Understanding the Trade-offs

While precision is paramount, it's important to view it within the context of your specific operational needs. The highest possible accuracy is not always the most cost-effective solution for every application.

The Cost of Precision

Systems offering the tightest temperature control—often employing advanced sensors like dual-wavelength pyrometers and sophisticated IGBT power supplies—come at a higher initial capital cost.

This investment must be weighed against the tangible value it will create by reducing scrap rates and energy consumption in your specific process.

Matching Accuracy to the Application

A foundry producing high-performance nickel-based superalloys for jet engine components requires far more stringent control than one casting standard-grade iron manhole covers.

The key is to define your required quality standard and choose a control system that reliably meets it without over-engineering the solution.

Making the Right Choice for Your Operation

The ideal level of temperature control is not a universal standard but a strategic choice based on your goals.

- If your primary focus is producing high-performance or specification-critical alloys: Invest in the highest-accuracy control system you can. The cost is justified by the absolute necessity of metallurgical consistency.

- If your primary focus is high-volume, standard-grade casting: A reliable, mid-range control system offers the best return on investment, providing significant defect reduction and efficiency gains without the cost of a top-tier system.

- If your primary focus is reducing operational costs: Conduct an audit of scrap rates and energy consumption. The data will often reveal that an upgrade to a more precise temperature control system pays for itself quickly.

Ultimately, superior temperature control transforms the furnace from a simple heat source into a precise manufacturing instrument.

Summary Table:

| Impact Area | Benefit of Precise Control |

|---|---|

| Product Quality | Prevents defects (porosity), ensures consistent alloy composition and mechanical properties. |

| Operational Cost | Reduces scrap rates, minimizes energy waste, and lowers rework costs. |

| Process Efficiency | Enables predictable melting, optimizes mold filling, and extends furnace lining life. |

Ready to transform your induction melting process into a precise manufacturing instrument?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions. Our high-temperature furnaces, including Vacuum & Atmosphere Furnaces, are engineered for superior control and consistency, directly addressing the critical need for accuracy in metal processing.

Whether you are producing high-performance alloys for aerospace or focusing on high-volume casting, our strong deep customization capability ensures your furnace system is tailored to meet your unique quality and efficiency targets.

Contact our experts today to discuss how a KINTEK solution can optimize your temperature control, reduce costs, and guarantee the metallurgical integrity of your products.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys