In the world of dental prosthetics, precise temperature control within a furnace is not merely a feature—it is the cornerstone of quality. It directly dictates the final strength, fit, aesthetic accuracy, and long-term durability of a restoration. Even minor temperature deviations can introduce imperfections, leading to compromised clinical outcomes and costly remakes.

The core purpose of a dental furnace is not simply to heat a material, but to guide it through a highly specific thermal transformation. Precise temperature control ensures this transformation happens correctly, yielding a restoration with the intended structural integrity and aesthetic properties.

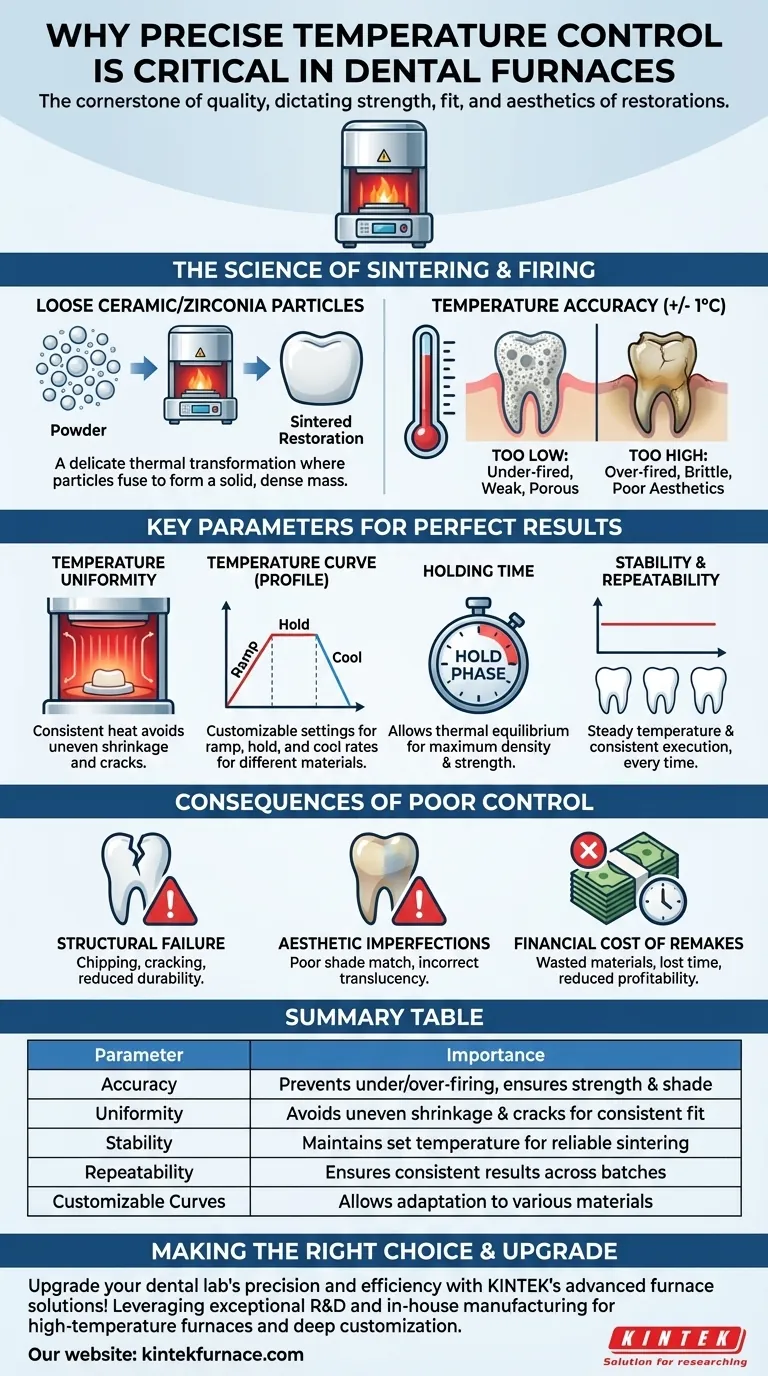

The Science of Sintering and Firing

A dental furnace facilitates a process like sintering, where ceramic or zirconia particles fuse together to form a solid, dense mass. This is a delicate physical and chemical transformation that is entirely dependent on a precise thermal "recipe."

Why Temperature Accuracy is Critical

The properties of dental ceramics are highly sensitive to temperature. A furnace with high accuracy—often within +/- 1°C—is essential.

If the temperature is too low, the material may not fully sinter, resulting in a porous, weak restoration prone to fracture. If it's too high, the material can over-fire, becoming brittle, slumping, or losing its desired shade and translucency.

The Role of Temperature Uniformity

Temperature uniformity means the temperature is consistent throughout the entire firing chamber.

Without it, different parts of the same restoration (or different restorations in the same batch) will be exposed to varying heat. This causes uneven shrinkage, leading to internal stress, poor marginal fit, or cracks.

Key Parameters of Temperature Control

Achieving a perfect result relies on managing several time-and-temperature variables. A high-quality furnace provides you with direct command over these factors.

The Temperature Curve (Profile)

Different materials require unique thermal journeys. The temperature curve, or firing profile, dictates the rate of temperature increase (ramp), the duration at peak temperature (hold), and the cooling rate.

Modern furnaces allow for customizable temperature curve settings, which is essential for labs that work with a wide variety of advanced materials, each with its own specific processing requirements.

The "Holding Time" Phase

Holding time is the specific period during which the furnace maintains the peak firing temperature.

This phase is not passive. It allows the entire restoration to reach thermal equilibrium, ensuring the sintering process completes fully and evenly throughout the material's volume for maximum density and strength.

Stability and Repeatability

Finally, stability ensures the furnace can hold a set temperature without fluctuation, while repeatability ensures it can execute the exact same temperature profile every single time. This is the key to achieving consistent, reliable results from one day to the next.

The Consequences of Poor Control

Failing to maintain precise temperature control has direct and significant consequences for any dental lab. These are not minor issues; they are fundamental failures that undermine the entire fabrication process.

Structural and Mechanical Failure

The most common outcome of poor temperature control is a restoration that lacks the required strength and durability. This can lead to chipping, cracking, or complete fracture after it has been placed, damaging both the patient's health and the lab's reputation.

Aesthetic Imperfections

Temperature has a profound impact on aesthetics. Incorrect firing can ruin the color and translucency of a porcelain or zirconia restoration, resulting in a poor shade match that is unacceptable to the dentist and patient.

The Financial Cost of Remakes

Every failed restoration is a significant loss. It represents wasted high-value materials, lost technician time, and delayed case delivery. The hidden cost of remakes due to inconsistent firing is one of the biggest threats to a lab's profitability.

Making the Right Choice for Your Goal

Selecting or evaluating a dental furnace should be based on its ability to deliver precise and repeatable thermal control. Your specific priorities will guide your decision.

- If your primary focus is consistency across batches: Prioritize a furnace with documented temperature stability and excellent chamber uniformity to eliminate variations.

- If your primary focus is working with diverse materials: Ensure your furnace offers flexible and easily customizable temperature curve settings to handle any material's unique demands.

- If your primary focus is maximizing quality and minimizing remakes: Invest in a furnace with the highest possible accuracy (e.g., +/- 1°C) and reliable, well-calibrated temperature sensors.

Ultimately, mastering temperature control gives you direct command over the quality and success of every restoration you produce.

Summary Table:

| Parameter | Importance in Dental Furnaces |

|---|---|

| Accuracy | Prevents under/over-firing, ensuring strength and correct shade |

| Uniformity | Avoids uneven shrinkage and cracks for consistent fit |

| Stability | Maintains set temperature for reliable sintering |

| Repeatability | Ensures consistent results across multiple batches |

| Customizable Curves | Allows adaptation to various materials for optimal outcomes |

Upgrade your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures they meet your unique experimental needs, reducing remakes and enhancing restoration quality. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations