At its core, isolation within a muffle furnace is critical because it prevents chemical reactions between the material being heated and unwanted contaminants. These contaminants, often byproducts of the heating process itself, can ruin the purity, structural integrity, and final properties of the sample.

A muffle furnace is not just a tool for high-temperature heating; it is a system designed to provide a chemically clean and controlled environment. The isolation it provides is the defining feature that ensures the results of a process are due to heat alone, not unpredictable contamination.

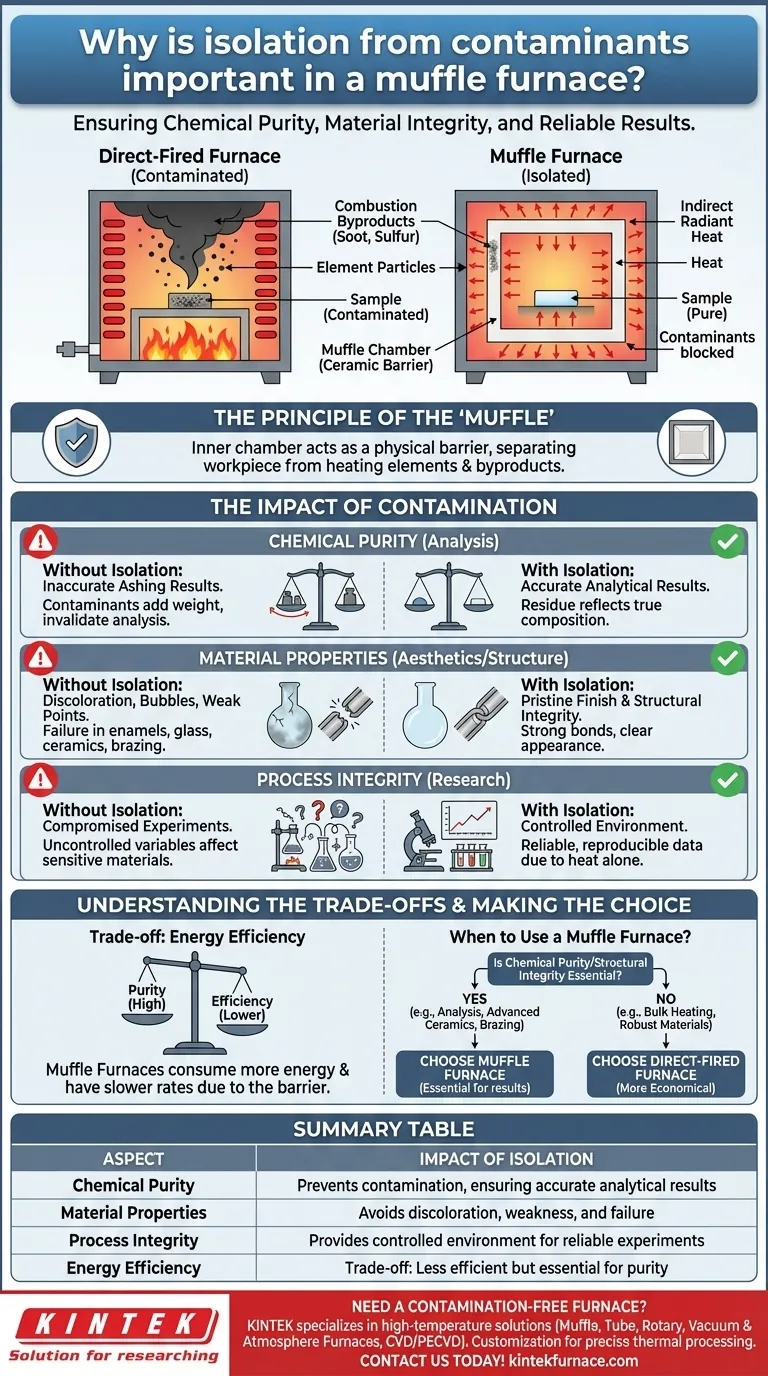

The Principle of the "Muffle"

What "Muffle" Means

The term "muffle" refers to the inner chamber, which acts as a physical barrier. This chamber, typically made of high-temperature ceramic, separates the workpiece from the actual heating elements or flames.

The furnace heats the outside of the muffle, and that heat radiates into the sealed inner chamber. The material inside is therefore heated indirectly.

The Source of Contamination

In a direct-fired furnace, the material is exposed to the byproducts of fuel combustion. These combustion byproducts, such as soot, sulfur, and unburnt gases, are highly reactive at high temperatures.

Even in electric furnaces without a muffle, particles from the heating elements can degrade and deposit onto the sample, introducing metallic or oxide impurities.

The Impact of Contamination on Materials

For Chemical Purity in Analysis

In analytical chemistry, processes like ashing are used to burn off all organic matter to precisely measure the inorganic residue.

If contaminants from the furnace add to this residue, the final weight is inaccurate. This invalidates the analysis, as the measurement no longer reflects the true composition of the original sample.

For Material Properties and Aesthetics

Contamination has a direct, negative impact on the final product in many applications.

For enamel coatings and glass melting, impurities cause discoloration, cloudiness, or bubbles, ruining the aesthetic and structural quality.

For technical ceramics and metal brazing, contaminants can interfere with the chemical bonding at the molecular level. This results in weak points, poor adhesion, and catastrophic failure of the component.

For Process Integrity in Research

In sensitive fields like nuclear materials science, any uncontrolled variable can compromise an entire experiment.

Using a muffle furnace ensures that observed changes in the material are a result of the controlled thermal cycle, not a random chemical reaction with an unknown contaminant.

Understanding the Trade-offs

The Cost of Indirect Heating

The primary trade-off of a muffle furnace is energy efficiency. Because heat must first pass through the muffle barrier, the furnace consumes more energy and can have slower heating and cooling rates compared to a direct-fired design.

This design makes muffle furnaces more expensive to operate for processes that do not require a pristine environment.

When a Muffle Isn't Necessary

Many high-temperature processes do not require isolation. For example, simple heat-treating of bulk steel or firing robust pottery often occurs in direct-fired kilns.

In these cases, minor surface contamination or discoloration is either acceptable, desired for aesthetic reasons, or easily removed in a subsequent finishing step.

Making the Right Choice for Your Goal

Selecting the correct type of furnace depends entirely on whether chemical purity is a requirement for your final outcome.

- If your primary focus is analytical precision or material purity: The controlled, isolated environment of a muffle furnace is absolutely essential.

- If your primary focus is the structural integrity of sensitive components: Use a muffle furnace to prevent contaminants from weakening chemical bonds in applications like brazing or advanced ceramics.

- If your primary focus is bulk heating where minor surface contamination is acceptable: A more energy-efficient, direct-fired furnace is likely the more economical choice.

Ultimately, understanding the role of the muffle allows you to choose the right tool to achieve a predictable and successful result.

Summary Table:

| Aspect | Impact of Isolation |

|---|---|

| Chemical Purity | Prevents contamination, ensuring accurate analytical results (e.g., in ashing) |

| Material Properties | Avoids discoloration, weakness, and failure in ceramics, metals, and coatings |

| Process Integrity | Provides controlled environment for reliable experiments and manufacturing |

| Energy Efficiency | Trade-off: less efficient than direct-fired furnaces but essential for purity |

Need a contamination-free furnace for your lab? KINTEK specializes in high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we tailor furnaces to your exact needs, ensuring precise thermal processing and reliable results. Contact us today to discuss how we can enhance your laboratory's performance and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing