The primary benefit of fast heating speed in channel induction furnaces is a direct increase in production efficiency. By significantly reducing the time required to melt metal, these furnaces allow for more cycles to be completed within a given shift, boosting overall throughput for foundries and metal casting operations.

Fast heating is more than a matter of speed; it is a strategic advantage. It directly translates into higher material quality by minimizing oxidation, greater energy efficiency by reducing heat loss, and ultimately, increased operational profitability.

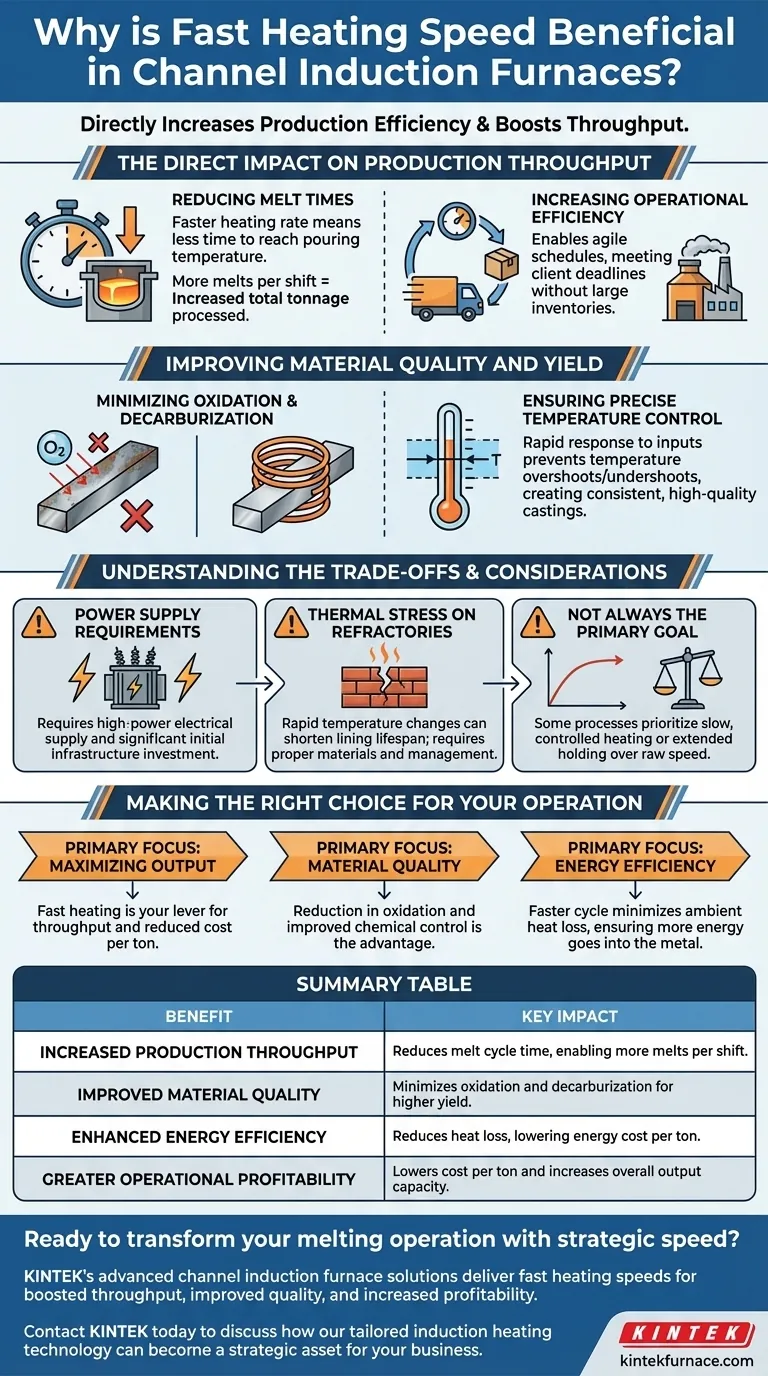

The Direct Impact on Production Throughput

A furnace's primary role is to process material. The speed at which it can perform this core function dictates the entire production line's pace and capacity.

Reducing Melt Times

The most obvious benefit is the reduction in cycle time. A faster heating rate means the metal charge reaches its target pouring temperature in less time.

This allows for more melts per shift, directly increasing the total tonnage of metal that can be processed.

Increasing Operational Efficiency

For industries like foundries that depend on quick turnarounds, rapid melting is essential.

It enables a more agile and responsive production schedule, allowing facilities to meet demanding client deadlines without maintaining large, costly inventories of molten metal.

Improving Material Quality and Yield

The quality of the final product is heavily influenced by the melting process. Speed plays a critical, and often underestimated, role in preserving the integrity of the metal.

Minimizing Oxidation and Decarburization

When metal is held at high temperatures, it reacts with oxygen in the atmosphere, leading to oxidation (metal loss) and decarburization (loss of carbon content in steel).

Fast heating minimizes the time the metal spends in this vulnerable state. This results in less material lost as slag and ensures the final alloy meets its precise chemical specifications, improving overall yield.

Ensuring Precise Temperature Control

Induction systems offer inherently precise temperature control. A fast heating speed enhances this capability.

The system can rapidly respond to inputs, preventing temperature overshoots that can damage alloys or undershoots that delay production. This precision is vital for creating high-quality, consistent castings.

Understanding the Trade-offs and Considerations

While highly beneficial, rapid heating speed is not a universal solution without context. Understanding its implications is key to proper implementation.

Power Supply Requirements

Achieving high heating rates requires a correspondingly high-power electrical supply. The initial capital investment in transformers, capacitors, and related infrastructure can be significant.

Thermal Stress on Refractories

Rapid and repeated temperature changes can induce thermal stress on the furnace's refractory lining. This can potentially shorten the lining's lifespan if not managed with proper materials and operating procedures.

Not Always the Primary Goal

In some metallurgical processes, a slow, controlled heating curve or extended holding at a specific temperature is more important than raw melting speed. In these cases, the furnace is optimized for stability rather than speed.

Making the Right Choice for Your Operation

The decision to prioritize heating speed should be aligned with your specific operational goals.

- If your primary focus is maximizing output: Fast heating is your most direct lever for increasing throughput and reducing the cost per ton.

- If your primary focus is material quality: The reduction in oxidation and improved chemical control from shorter melt times is a major advantage.

- If your primary focus is energy efficiency: A faster cycle minimizes the time for ambient heat loss, ensuring more energy goes directly into the metal.

Ultimately, leveraging fast heating speed transforms the channel induction furnace from a simple melting tool into a strategic asset for a more productive and profitable operation.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Increased Production Throughput | Reduces melt cycle time, enabling more melts per shift. |

| Improved Material Quality | Minimizes oxidation and decarburization for higher yield. |

| Enhanced Energy Efficiency | Reduces heat loss, lowering energy cost per ton. |

| Greater Operational Profitability | Lowers cost per ton and increases overall output capacity. |

Ready to transform your melting operation with strategic speed?

KINTEK's advanced channel induction furnace solutions are engineered to deliver the fast heating speeds that directly boost your production throughput, improve metal quality, and increase profitability. Leveraging our exceptional R&D and in-house manufacturing, we provide foundries and metal casting operations with robust, high-performance furnaces complemented by deep customization capabilities to meet your unique process requirements.

Contact KINTEL today to discuss how our tailored induction heating technology can become a strategic asset for your business.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting