Choosing the right porcelain furnace is not merely an equipment purchase; it is a foundational decision that directly dictates the quality, consistency, and profitability of your dental laboratory. The furnace controls the final physical and aesthetic properties of every ceramic restoration you produce, from strength and durability to shade and translucency. An unsuitable furnace can lead to inconsistent results, material failures, and costly remakes.

A porcelain furnace is more than a heat source—it is the instrument that transforms raw ceramic materials into high-performance dental restorations. Selecting the right one is about ensuring predictable outcomes, minimizing production errors, and safeguarding your lab's reputation for quality.

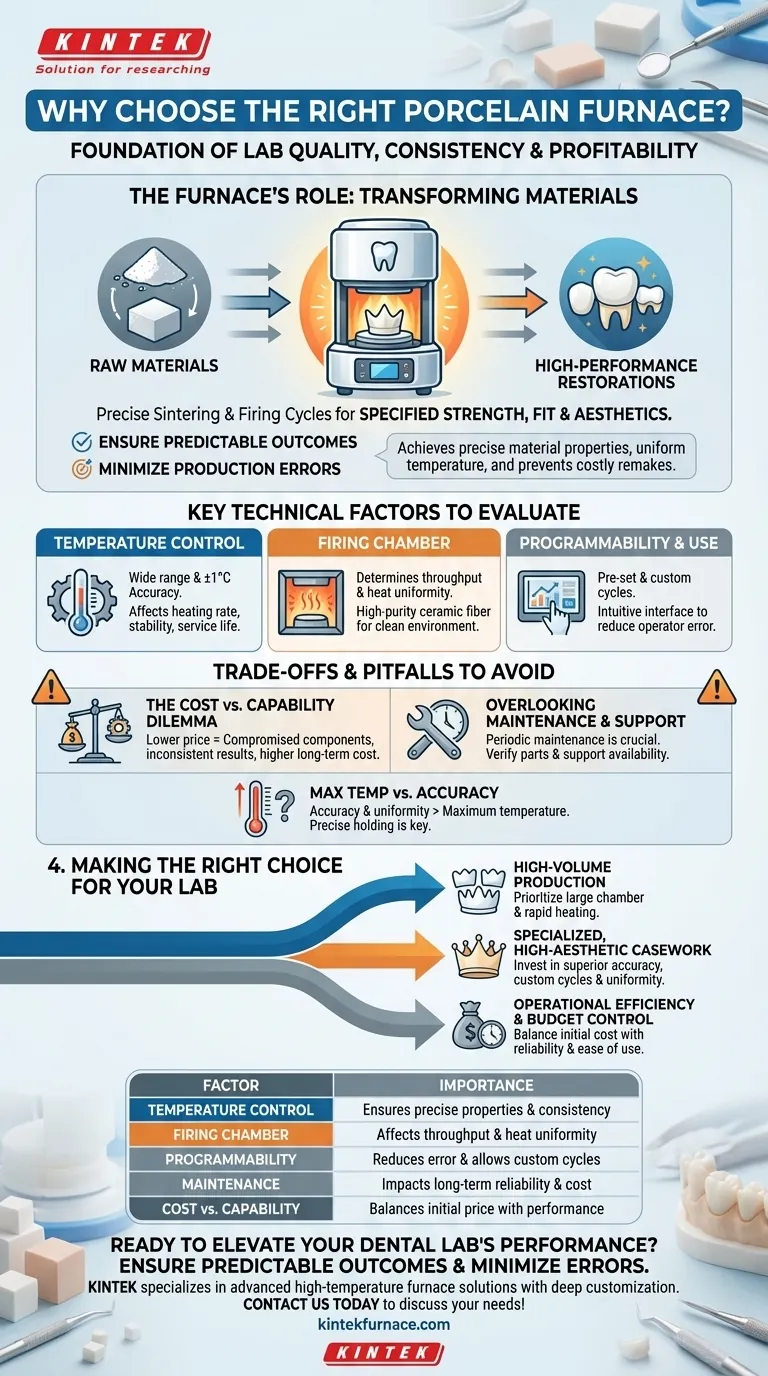

The Furnace's Role in a High-Quality Restoration

The core function of a porcelain furnace is to execute a precise, time-and-temperature-controlled heating cycle. This process, known as sintering or firing, is what gives a dental ceramic its final properties.

Achieving Precise Material Properties

Modern dental materials like zirconia and lithium disilicate have very specific firing schedules provided by the manufacturer. Adhering to these cycles is critical for achieving the specified strength, fit, and aesthetic characteristics. A high-quality furnace ensures these complex temperature protocols are followed exactly.

Ensuring Consistency and Predictability

The furnace must provide uniform temperature distribution throughout its firing chamber. This eliminates "hot spots" and "cold spots" that can cause inconsistencies across a single restoration or between multiple units in the same batch. Precise temperature control ensures that every restoration you produce meets the same high standard.

Preventing Costly Remakes

Firing errors are a primary cause of failed restorations. Issues like cracks, poor shade matching, or an improper fit often trace back to inaccurate temperature or uneven heating. A reliable furnace minimizes these failures, reducing the significant costs in time, labor, and materials associated with remakes.

Key Technical Factors to Evaluate

When comparing furnaces, look beyond the marketing and focus on the technical specifications that have a direct impact on performance and reliability.

Temperature Control and Heating Technology

This is the single most important factor. The furnace must offer a wide temperature range (often up to 1,200°C or higher) to handle diverse materials. More importantly, it must maintain temperature accuracy (e.g., ±1°C) throughout the entire cycle. The type of heating element (such as quartz tube or silicon carbide) also impacts the heating rate, stability, and service life.

Firing Chamber Size and Construction

The chamber size determines your lab's throughput, or how many units you can fire at once. The chamber material, typically a high-purity ceramic fiber, is crucial for maintaining a clean firing environment and ensuring excellent heat uniformity.

Programmability and Ease of Use

A modern furnace should come with pre-set programs for common materials but also allow for the creation of fully custom firing cycles. The user interface should be intuitive, reducing the potential for operator error and minimizing training time for technicians.

Understanding the Trade-offs and Pitfalls

Making an informed decision requires understanding the common compromises and mistakes labs make when investing in a new furnace.

The Cost vs. Capability Dilemma

Lower-priced furnaces can be tempting, but they often compromise on critical components like the temperature controller or heating elements. This can lead to inconsistent results and a shorter lifespan, making the long-term cost of ownership (due to remakes and repairs) much higher than that of a premium, reliable unit.

Overlooking Maintenance and Support

A furnace is a long-term investment that requires periodic maintenance, such as calibration and heating element replacement. Before purchasing, verify the availability and cost of replacement parts and technical support from the manufacturer. Extended downtime waiting for a part can cripple a lab's production.

Focusing Only on Maximum Temperature

While a high maximum temperature indicates versatility, it is not the most critical metric. Temperature accuracy and uniformity at all stages of the firing cycle are far more vital for achieving high-quality clinical outcomes. A furnace that can hold a precise temperature is more valuable than one that can simply reach a high one.

Making the Right Choice for Your Lab

Your final decision should align with your lab's specific operational needs and business goals.

- If your primary focus is high-volume production: Prioritize a furnace with a larger firing chamber and rapid, reliable heating rates to maximize throughput without sacrificing quality.

- If your primary focus is specialized, high-aesthetic casework: Invest in a furnace with superior temperature accuracy, advanced programmability for custom cycles, and exceptional heat uniformity.

- If your primary focus is operational efficiency and budget control: Balance the initial purchase price with long-term reliability, ease of use for your technicians, and the availability of affordable maintenance from the manufacturer.

Ultimately, the right furnace is a strategic asset that consistently delivers predictable, high-quality results, safeguarding your lab's reputation and profitability.

Summary Table:

| Factor | Importance |

|---|---|

| Temperature Control | Ensures precise material properties and consistency |

| Firing Chamber | Affects throughput and heat uniformity |

| Programmability | Reduces operator error and allows custom cycles |

| Maintenance | Impacts long-term reliability and cost of ownership |

| Cost vs. Capability | Balances initial price with performance and durability |

Ready to elevate your dental lab's performance? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for laboratories like yours. Leveraging our exceptional R&D and in-house manufacturing, we offer products including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Ensure predictable outcomes and minimize production errors—contact us today to discuss how our furnaces can enhance your quality and profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique