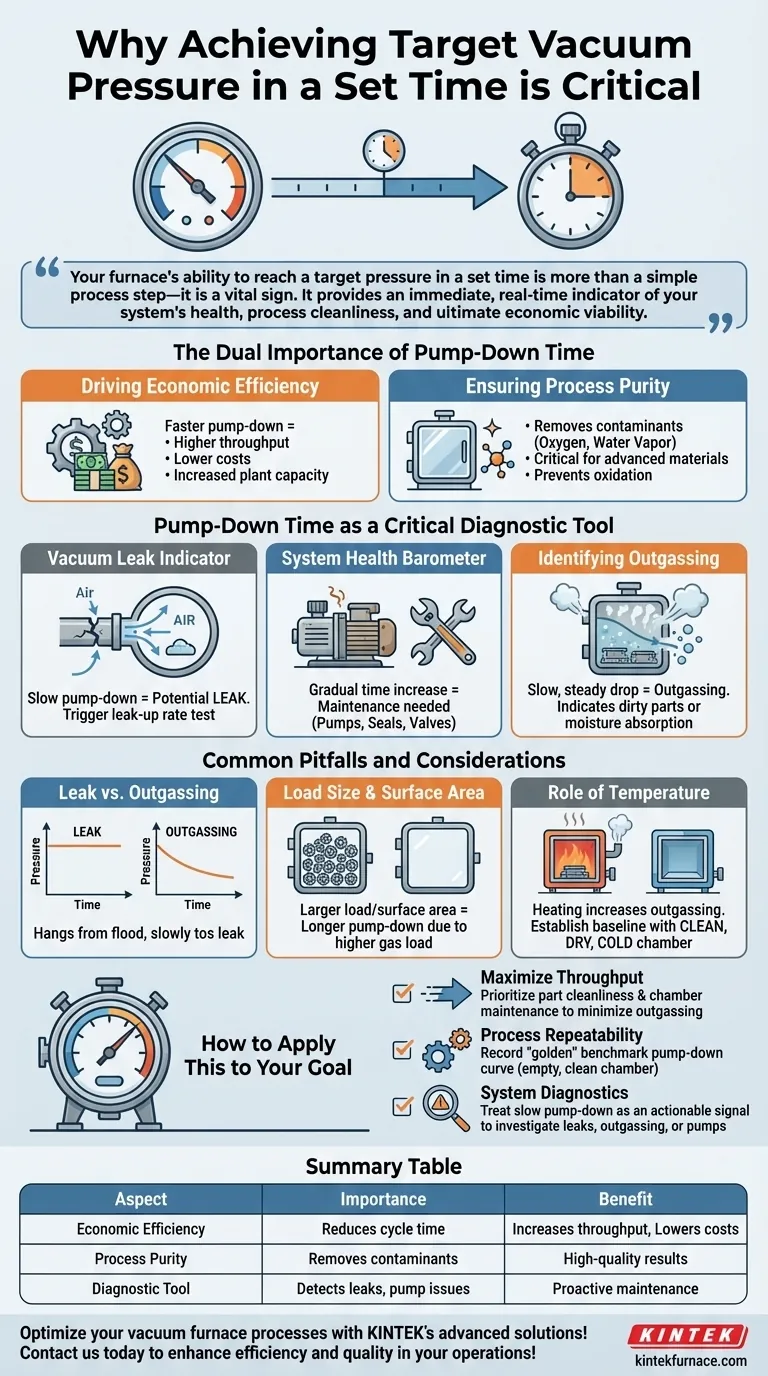

In vacuum furnace operations, achieving a target pressure within a specific time is a critical benchmark for two primary reasons: it ensures the economic efficiency of the process and guarantees the required atmospheric purity for quality results. Failing to meet this time-based goal signals a potential problem with the system or the process itself.

Your furnace's ability to reach a target pressure in a set time is more than a simple process step—it is a vital sign. It provides an immediate, real-time indicator of your system's health, process cleanliness, and ultimate economic viability.

The Dual Importance of Pump-Down Time

The time it takes to evacuate a vacuum furnace chamber, known as the pump-down time, serves two fundamental purposes that are intertwined.

Driving Economic Efficiency

A core goal in any industrial process is to maximize throughput. The evacuation phase is often non-productive time, so shortening it directly translates to financial gain.

Faster pump-down cycles mean more batches can be processed in a day, increasing overall plant capacity without adding new equipment. This also reduces energy consumption and labor costs per cycle.

Ensuring Process Purity

Many advanced material processes, such as brazing or heat treating, are highly sensitive to atmospheric contaminants. The vacuum environment is created specifically to remove these reactive gases.

The most common substance to remove is oxygen, which can cause unwanted oxidation on the surface of parts, compromising their structural integrity or performance. Removing water vapor and other gases is also critical for achieving a pure, inert environment necessary for high-quality outcomes.

Pump-Down Time as a Critical Diagnostic Tool

Beyond its direct process functions, the pump-down curve (the plot of pressure vs. time) is the single most important diagnostic tool for a vacuum furnace operator. A deviation from the expected time is the first warning sign of a problem.

The Primary Indicator of a Vacuum Leak

If the furnace takes longer than usual to reach its target pressure, the most common culprit is a leak. This means air from the outside is entering the chamber, working against the vacuum pumps.

A slow pump-down rate is the initial symptom that should trigger a more formal leak-up rate test, where the chamber is isolated from the pumps to measure how quickly pressure rises. This confirms the presence and severity of a leak.

A Barometer for System Health

Tracking pump-down time over weeks and months provides invaluable data on the health of your entire vacuum system.

A gradual increase in evacuation time can signal that your vacuum pumps require maintenance, that seals are beginning to degrade, or that valves are not closing completely. This allows for proactive maintenance before a catastrophic failure occurs.

Identifying Outgassing Problems

Sometimes, a slow pump-down is not caused by a leak but by outgassing. This is the release of trapped gases and vapors (especially water) from the surfaces of the parts, fixtures, or the chamber walls themselves.

While not a system fault, excessive outgassing indicates a problem with process cleanliness. It may mean parts were not cleaned properly or that the chamber itself has absorbed moisture from being open to the atmosphere.

Common Pitfalls and Considerations

To use pump-down time effectively as a diagnostic tool, you must understand the variables that influence it.

Distinguishing a Leak from Outgassing

This is the most common diagnostic challenge. A true leak typically causes the pressure to level off or "hang" at a certain point. Outgassing, on the other hand, usually presents as a very slow but steady decrease in pressure as the gas load diminishes over time.

The Impact of Load Size and Surface Area

A larger load or a load with a high surface area (like many small parts) will naturally have a higher gas load due to outgassing. This will extend the pump-down time compared to an empty chamber.

The Role of Temperature

As a furnace heats up, the rate of outgassing from all internal surfaces increases dramatically. It is essential to establish your baseline pump-down time with a clean, dry, and empty chamber at ambient temperature. This creates a reliable benchmark for comparison.

How to Apply This to Your Goal

Use your pump-down time as a precise instrument to manage your vacuum furnace operations.

- If your primary focus is maximizing throughput: Prioritize part cleanliness and chamber maintenance to minimize outgassing, as this is often a major source of extended cycle times.

- If your primary focus is process repeatability: Always record the pump-down curve for an empty, clean chamber to establish a "golden" benchmark for all future diagnostic checks.

- If your primary focus is system diagnostics: Treat a longer-than-expected pump-down time as the first actionable signal to investigate for leaks, outgassing, or pump performance issues.

Ultimately, mastering the relationship between pressure and time gives you direct control over the quality, efficiency, and reliability of your entire vacuum process.

Summary Table:

| Aspect | Importance |

|---|---|

| Economic Efficiency | Reduces cycle time, increases throughput, lowers costs per batch |

| Process Purity | Removes contaminants like oxygen and water vapor for high-quality results |

| Diagnostic Tool | Detects leaks, pump issues, and outgassing for proactive maintenance |

Optimize your vacuum furnace processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance efficiency and quality in your operations!

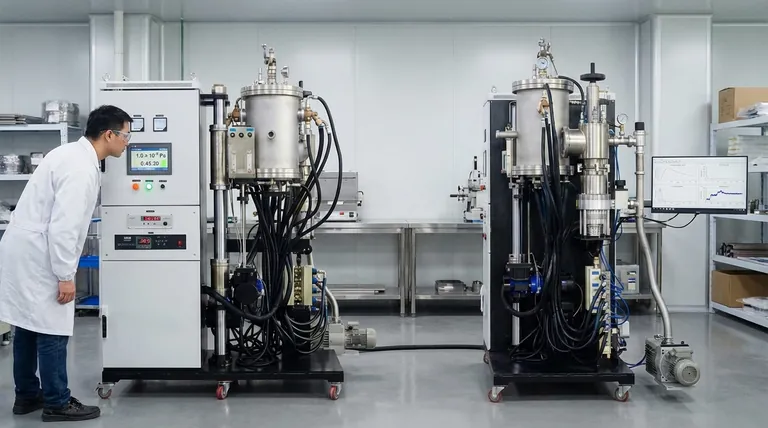

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process