The primary function of a solvent bubbler in a Chemical Vapor Deposition (CVD) system is to introduce gaseous catalysts or auxiliary solvents into the reaction environment with high precision. By passing a carrier gas through a liquid solvent, the system transports a specific concentration of chemical vapor to the furnace to regulate the growth of the material.

Core Takeaway: The synthesis of 2D Covalent Organic Frameworks (COFs) requires a delicate balance of reaction speed and reversibility. A solvent bubbler creates a "gas-phase assisted" environment that modulates polymerization kinetics, which is critical for transforming simple monomers into highly ordered, crystalline 2D structures.

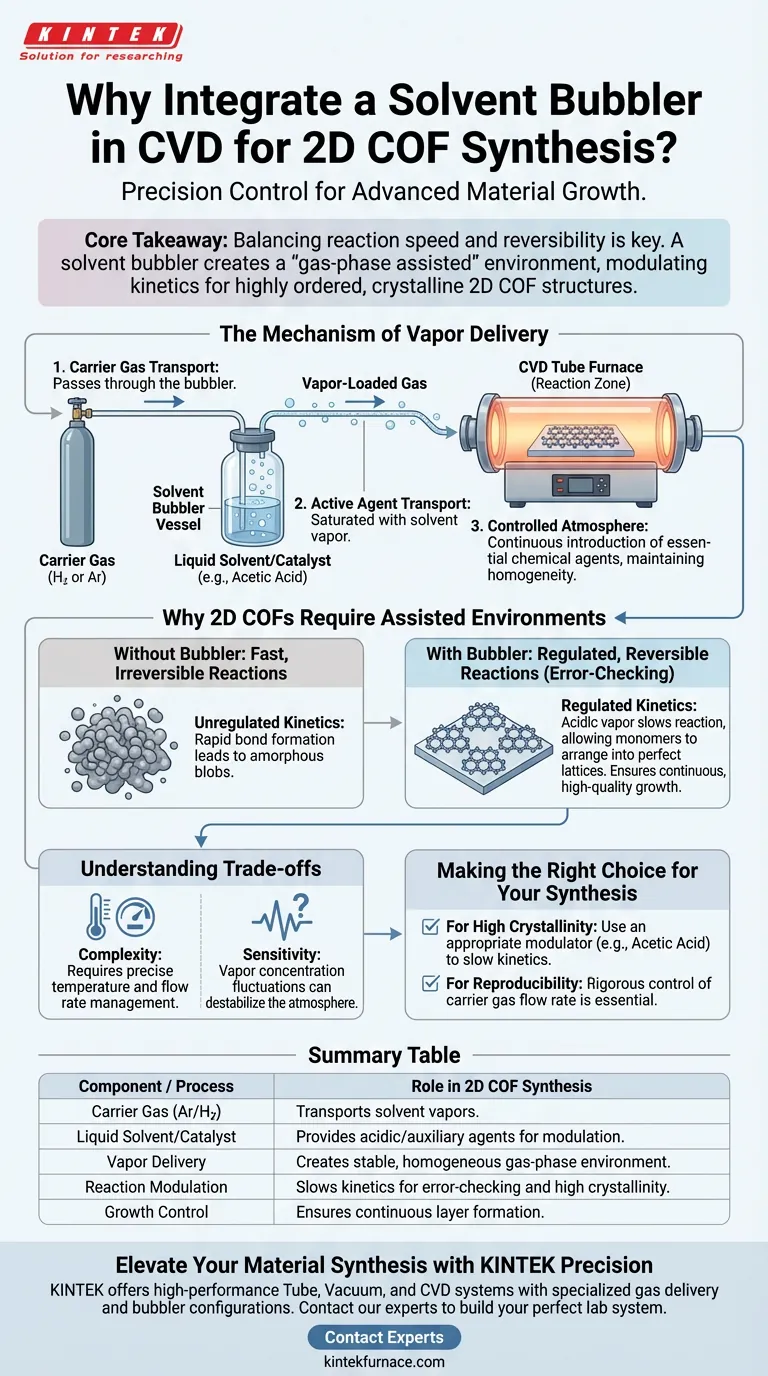

The Mechanism of Vapor Delivery

Utilizing Carrier Gases

The process begins with a carrier gas, typically hydrogen or argon. This gas is directed through the bubbler vessel which contains a specific liquid solvent or catalyst, such as acetic acid.

Transporting Active Agents

As the gas bubbles through the liquid, it becomes saturated with solvent vapor. This vapor-loaded gas is then transported into the main reaction zone of the tube furnace.

Creating a Controlled Atmosphere

This mechanism allows for the continuous introduction of essential chemical agents without using liquid injection. It maintains a stable, homogeneous reaction atmosphere throughout the synthesis process.

Why 2D COFs Require Assisted Environments

Regulating Polymerization Kinetics

The formation of Covalent Organic Frameworks relies on reversible chemistry. If the reaction happens too quickly, the material creates irreversible bonds and becomes an amorphous blob.

Improving Crystalline Quality

The vapor introduced by the bubbler (often an acidic catalyst) slows the reaction or makes it reversible. This "error-checking" process allows the monomers to arrange themselves into perfect, periodic 2D lattices.

Ensuring Continuous Growth

Standard CVD provides high temperatures for precursor reaction. The bubbler supplements this by ensuring the chemical environment remains chemically active enough to support continuous layer growth on the substrate.

Understanding the Trade-offs

Complexity of Process Control

While a bubbler adds necessary chemical control, it introduces new variables to the system. You must precisely manage the temperature of the bubbler and the flow rate of the carrier gas.

Sensitivity to Saturation Limits

If the carrier gas flow is too high, it may not pick up enough solvent vapor. Conversely, fluctuations in the bubbler's temperature can lead to inconsistent vapor concentrations, potentially destabilizing the reaction atmosphere.

Making the Right Choice for Your Synthesis

To optimize your CVD system for 2D COF growth, consider your specific experimental targets:

- If your primary focus is High Crystallinity: Ensure your bubbler contains an appropriate modulator (like acetic acid) to slow down kinetics and allow for ordered lattice formation.

- If your primary focus is Reproducibility: rigorous control of the carrier gas flow rate through the bubbler is essential to maintain a stable gas-phase concentration across different runs.

The solvent bubbler turns a standard deposition instrument into a precision chemistry tool capable of synthesizing complex organic architectures.

Summary Table:

| Component / Process | Role in 2D COF Synthesis |

|---|---|

| Carrier Gas (Ar/H2) | Transports solvent vapors into the reaction zone. |

| Liquid Solvent/Catalyst | Provides acidic/auxiliary agents to modulate reaction speed. |

| Vapor Delivery | Creates a stable, homogeneous gas-phase environment. |

| Reaction Modulation | Slows kinetics to enable error-checking for high crystallinity. |

| Growth Control | Ensures continuous layer formation on the substrate. |

Elevate Your Material Synthesis with KINTEK Precision

High-performance 2D COF synthesis requires more than just heat; it demands precise chemical control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, and CVD systems—including specialized gas delivery and bubbler configurations—designed to meet your unique lab requirements. Whether you are optimizing polymerization kinetics or scaling up production, our customizable high-temperature solutions provide the stability and precision your research deserves.

Ready to achieve superior crystalline quality? Contact our technical experts today to build the perfect CVD system for your lab.

Visual Guide

References

- Jin Hyuk Cho, Soo Young Kim. Advancements in two-dimensional covalent organic framework nanosheets for electrocatalytic energy conversion: current and future prospects. DOI: 10.20517/energymater.2023.72

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of using CVD for CNC machining? Boost Durability and Efficiency in Precision Parts

- Why is surface passivation important for CVD coatings? Ensure Strong, Defect-Free Film Growth

- What roles do PVD and CVD play in modern thin-film technology? Key Differences and Applications Explained

- Why is temperature control precision critical for CdS nanobelt synthesis? Master PVD Precision for Nano-Quality

- What is the basic configuration of CVD coating equipment? Unlock High-Quality Thin Film Deposition

- What role do high-purity quartz boats play during the chemical vapor deposition (CVD) of MoS2? Optimize Thin-Film Growth

- What materials can be deposited using CVD? Unlock Versatile Thin Films for Your Applications

- What is the primary role of heating filaments within an iCVD process? Enabling Low-Temperature Polymerization