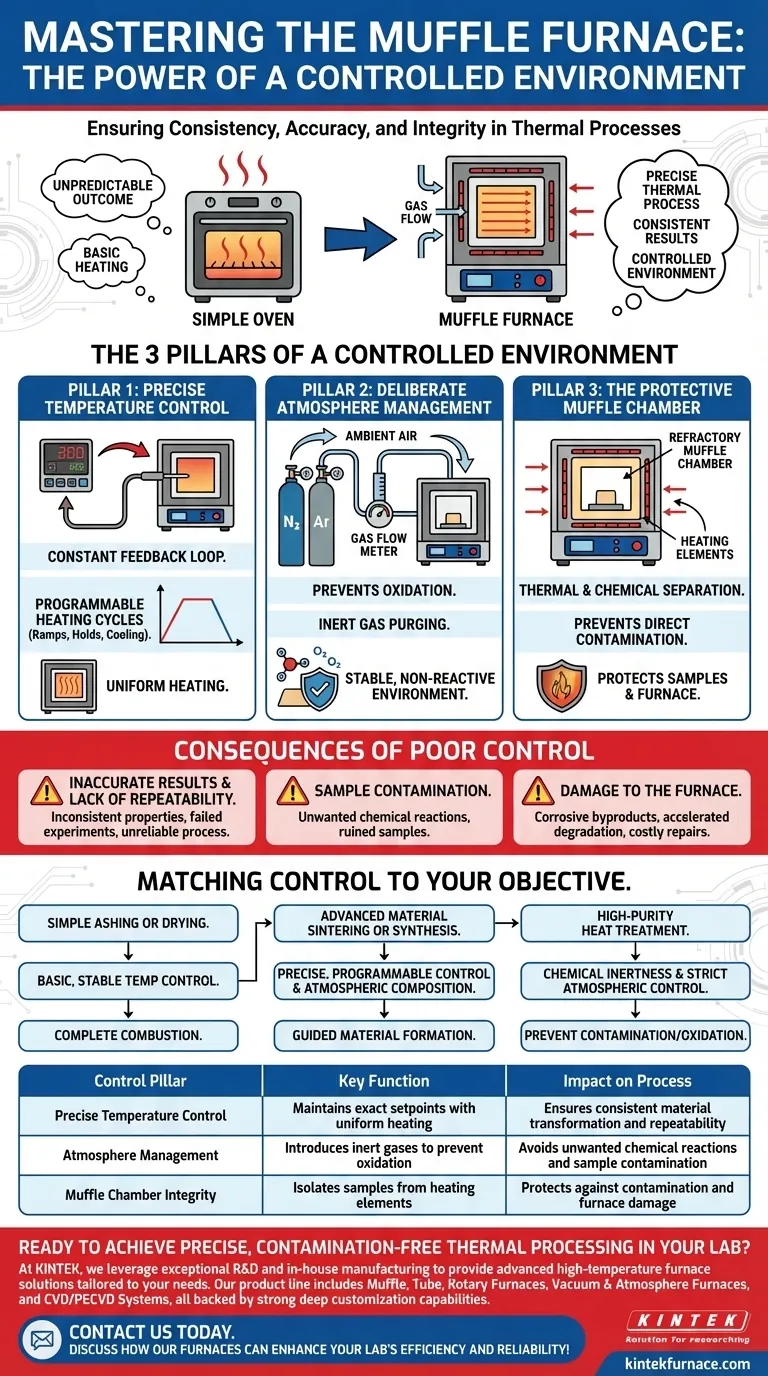

In essence, a controlled environment is what separates a muffle furnace from a simple oven. This control is the mechanism that ensures processes like ashing, sintering, or heat treatment produce consistent, accurate results. Without it, you are not performing a precise thermal process; you are merely heating a sample with an unpredictable outcome.

A muffle furnace's value is not just its ability to get hot, but its ability to create a highly stable and chemically isolated environment. This control over temperature and atmosphere is the fundamental requirement for achieving repeatable results and preventing the contamination that can invalidate an entire experiment or production run.

The Pillars of a Controlled Environment

A truly controlled environment in a muffle furnace stands on three critical pillars: precise temperature management, deliberate atmospheric conditions, and the integrity of the physical chamber.

Pillar 1: Precise Temperature Control

A controller and temperature sensor form a constant feedback loop. The sensor, or thermometer, monitors the chamber's internal temperature and feeds this data to the controller.

The controller then adjusts the electrical power sent to the heating elements to maintain the exact setpoint temperature, preventing over- or undershooting.

Modern programmable controllers allow for complex heating cycles. You can define specific ramp-up rates (how fast it heats), hold times (how long it stays at a temperature), and cooling periods, ensuring the entire process is repeatable.

Furthermore, uniform heating is essential. The furnace is designed to distribute heat evenly, ensuring the entire sample experiences the same thermal conditions for consistent material transformation.

Pillar 2: Deliberate Atmosphere Management

Many materials react with oxygen at high temperatures, a process known as oxidation. A controlled atmosphere prevents these unwanted chemical reactions.

This is achieved by introducing specific gases, such as nitrogen or argon, into the chamber. A gas flow meter is used to regulate the introduction of these gases, creating a stable and inert (non-reactive) environment.

By purging the ambient air, you ensure that the only reactions occurring are the ones you intend as part of your heat treatment process.

Pillar 3: The Protective Muffle Chamber

The "muffle" itself—the inner chamber—is a core component of control. It provides critical thermal and chemical separation.

It physically isolates your samples from the raw heating elements. This prevents direct contamination and any potential electrical interference, ensuring the process remains pure.

Made from refractory materials like alumina, the muffle is chemically resistant and can withstand repeated, extreme temperature changes without degrading and shedding particles onto your samples. This protects both the sample from the furnace and the furnace elements from corrosive byproducts of the process.

Understanding the Consequences of Poor Control

Failing to maintain a controlled environment doesn't just lead to slightly different results; it can completely invalidate your work and damage your equipment.

Inaccurate Results and Lack of Repeatability

If the temperature fluctuates or is not uniform across the sample, the material's final properties will be inconsistent. This makes it impossible to reliably repeat an experiment or manufacturing process.

Sample Contamination

An uncontrolled atmosphere is the most common source of failure. Unwanted oxidation or reactions with ambient air can completely change the chemical makeup and physical properties of your material, ruining the sample.

Damage to the Furnace

Process byproducts, such as fumes or vapors, can be highly corrosive to heating elements. The muffle chamber contains these byproducts, but poor atmospheric control or exceeding temperature limits can accelerate furnace degradation and lead to costly repairs. Safety features like over-temperature protection exist as a final line of defense.

Matching Control to Your Objective

The necessary level of control is dictated entirely by your process goals. Use this guide to determine what is most important for your application.

- If your primary focus is simple ashing or drying: Basic, stable temperature control is your main priority to ensure complete combustion without damaging the sample.

- If your primary focus is advanced material sintering or synthesis: You require precise, programmable control over both the temperature cycle (ramps and holds) and the atmospheric composition to guide material formation.

- If your primary focus is high-purity heat treatment: The chemical inertness of the muffle and strict atmospheric control are the most critical factors to prevent unwanted oxidation or contamination.

Mastering your furnace's controlled environment is mastering the outcome of your work.

Summary Table:

| Control Pillar | Key Function | Impact on Process |

|---|---|---|

| Precise Temperature Control | Maintains exact setpoints with uniform heating | Ensures consistent material transformation and repeatability |

| Atmosphere Management | Introduces inert gases to prevent oxidation | Avoids unwanted chemical reactions and sample contamination |

| Muffle Chamber Integrity | Isolates samples from heating elements | Protects against contamination and furnace damage |

Ready to achieve precise, contamination-free thermal processing in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Don't let poor control compromise your results—contact us today to discuss how our furnaces can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating