In any high-integrity joining process, the goal is not just to melt a filler metal but to create a flawless metallurgical bond. Muffle furnaces are critical for soldering and brazing because they provide highly uniform heat within a tightly controlled atmosphere. This dual capability ensures the filler metal flows properly while protecting both the filler and the base metals from oxidation, resulting in a clean, strong, and highly repeatable joint.

The true value of a muffle furnace for brazing and soldering is not simply its ability to get hot. Its primary importance lies in creating a chemically controlled atmosphere, which is essential for preventing the oxidation that otherwise ruins the integrity and strength of the final bond.

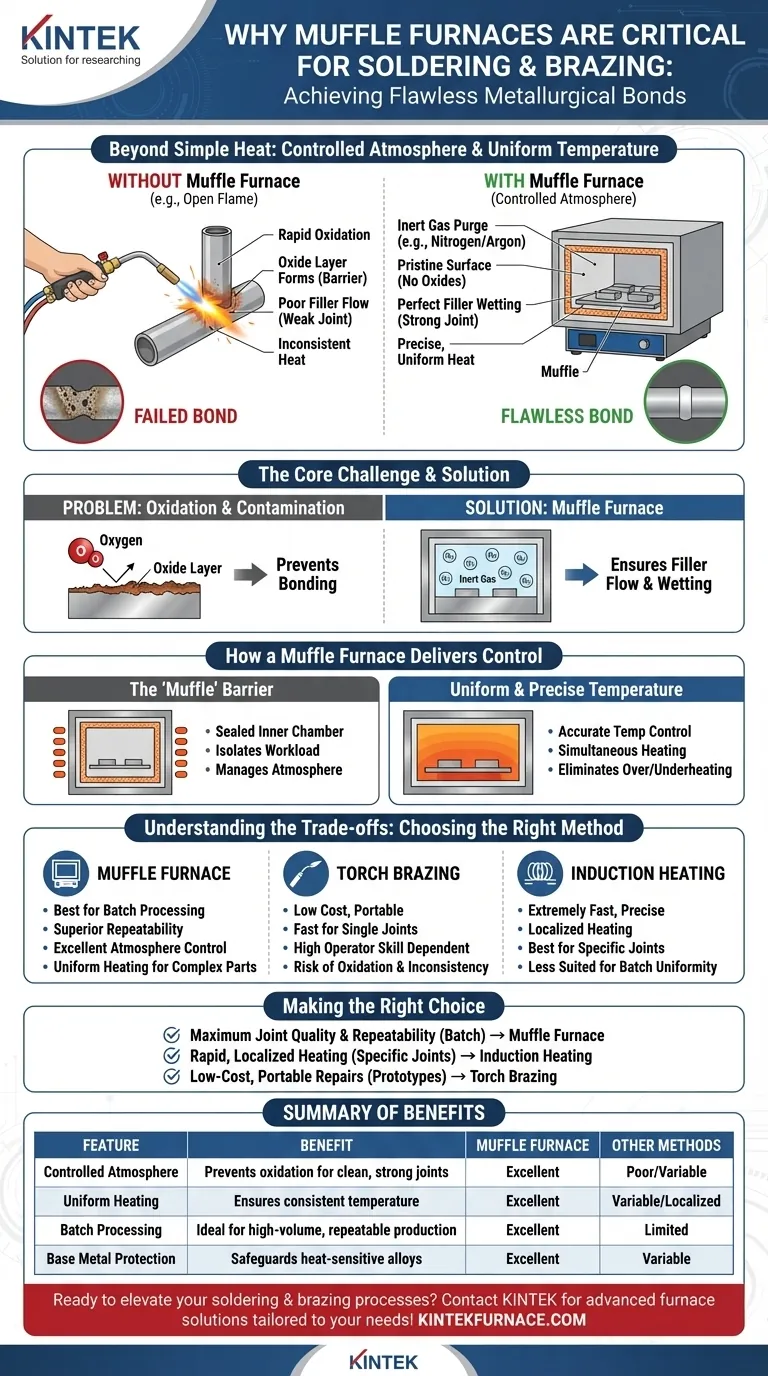

Beyond Simple Heat: The Role of Atmosphere Control

The core challenge in any high-temperature joining process is managing the chemical reactions that occur on the metal's surface. A muffle furnace is engineered specifically to solve this problem.

Preventing Oxidation and Contamination

At brazing temperatures, metals react rapidly with oxygen in the air. This forms a layer of oxides on the surface of the parts.

This oxide layer acts as a barrier, preventing the molten filler metal from "wetting" the base metal and forming a proper metallurgical bond, leading to a weak or failed joint.

A controlled atmosphere muffle furnace solves this by first purging the air from its sealed chamber and replacing it with an inert gas like nitrogen or argon.

Ensuring Filler Metal Flow and Wetting

By operating in an inert, oxygen-free environment, the metal surfaces remain pristine and chemically active.

This allows the molten filler material to flow freely into the joint through capillary action. The result is a complete, void-free bond that utilizes the full strength of the brazing alloy.

Maintaining Base Metal Integrity

The precise, uniform heat and protective atmosphere also prevent the base metals themselves from being damaged.

This is critical for heat-sensitive alloys or thin-walled components that could be weakened or distorted by the uncontrolled, intense heat of an open flame.

How a Muffle Furnace Delivers Control

The unique construction of a muffle furnace is what enables this level of process control, leading to superior part uniformity and higher production yields.

The "Muffle" as a Protective Barrier

The defining feature is the muffle itself—a sealed inner chamber (or retort) that holds the parts.

This muffle isolates the workload from the heating elements and the outside environment, creating a contained space where the atmosphere can be precisely managed.

Uniform and Precise Temperature

High-quality insulation and modern controllers allow the furnace to achieve and hold a specific temperature with extreme accuracy across the entire chamber.

This uniform heating ensures that all parts of the assembly, and all assemblies in a batch, reach the correct brazing temperature simultaneously. This eliminates issues of overheating some areas while underheating others.

Understanding the Trade-offs: Muffle vs. Other Methods

While powerful, a muffle furnace is not the only tool for brazing. Understanding its advantages and disadvantages compared to other common methods is key to making the right choice.

Muffle Furnace vs. Torch Brazing

Torch brazing uses an open flame. It is inexpensive, portable, and fast for single joints. However, it is highly dependent on operator skill to manage heat and minimize oxidation, making it difficult to achieve consistent, high-quality results.

In contrast, a muffle furnace is ideal for batch processing, offering vastly superior repeatability and joint quality by removing operator variability and atmospheric contamination from the equation.

Muffle Furnace vs. Induction Heating

Induction heating uses electromagnetic fields to generate rapid, localized heat directly at the joint. It is extremely fast and precise for specific, well-defined areas.

A muffle furnace heats the entire part or assembly uniformly. This makes it better suited for complex geometries with multiple joints or when the entire part benefits from a controlled thermal cycle. It's a choice between localized heat (induction) and uniform batch heating (muffle).

Making the Right Choice for Your Application

Selecting the right heating method requires a clear understanding of your project's technical requirements and production goals.

- If your primary focus is maximum joint quality and repeatability for batch production: A controlled atmosphere muffle furnace is the superior choice due to its precise control over temperature and atmosphere.

- If your primary focus is rapid, localized heating for specific joints on an assembly line: Induction heating offers unparalleled speed and precision for targeted areas.

- If your primary focus is low-cost, portable repairs or one-off prototypes: Manual torch brazing is a viable option, but it requires significant operator skill to manage heat and oxidation.

Ultimately, selecting the correct heating method requires matching the process capabilities to the specific quality, volume, and cost requirements of your project.

Summary Table:

| Feature | Benefit |

|---|---|

| Controlled Atmosphere | Prevents oxidation for clean, strong joints |

| Uniform Heating | Ensures consistent temperature across all parts |

| Batch Processing | Ideal for high-volume, repeatable production |

| Base Metal Protection | Safeguards heat-sensitive alloys from damage |

Ready to elevate your soldering and brazing processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need uniform batch heating or controlled atmospheres for flawless joints, we can help you achieve superior results. Contact us today to discuss how our solutions can enhance your productivity and quality!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation