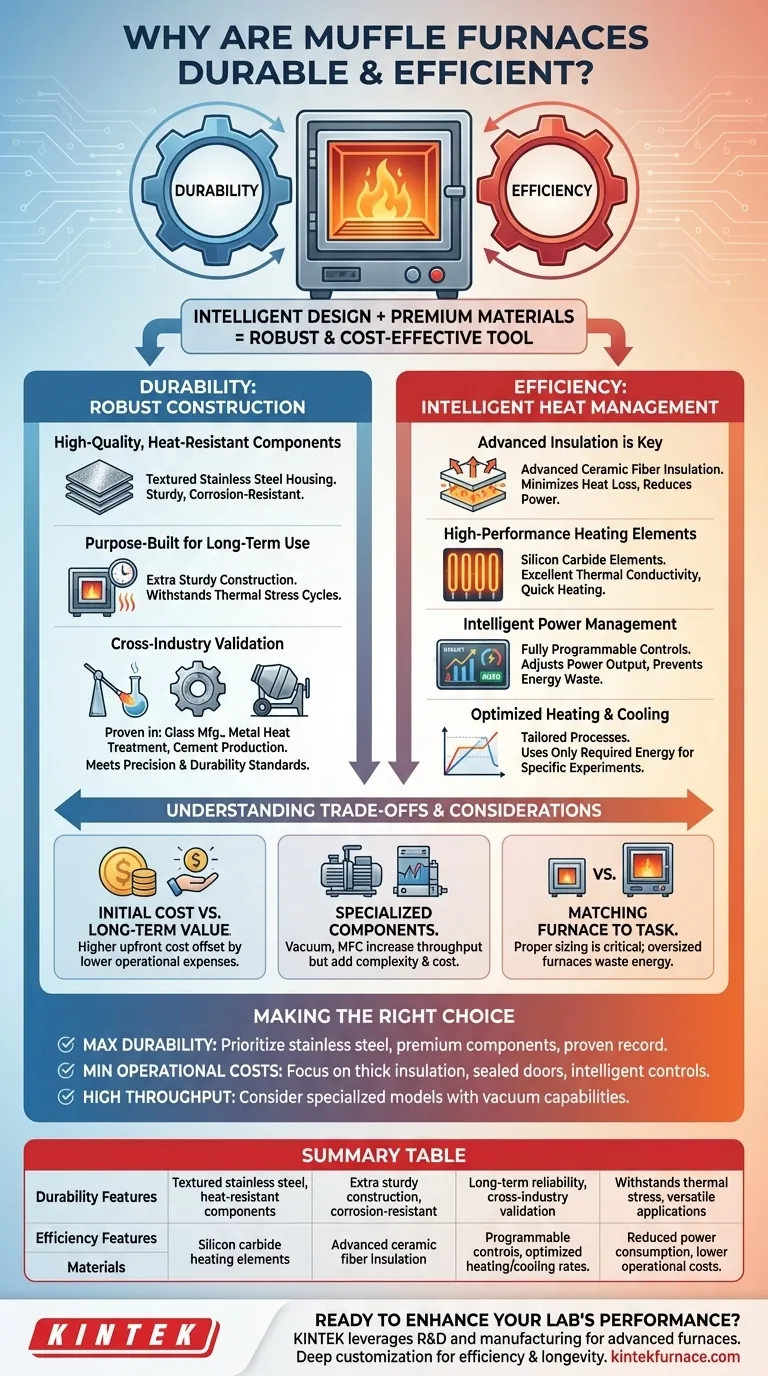

At their core, muffle furnaces are considered durable and efficient due to a deliberate combination of high-quality, heat-resistant materials and intelligent design that minimizes heat loss. Their construction prioritizes retaining energy within the chamber, while programmable controls ensure that energy is used only when and where it is needed, resulting in a robust and cost-effective tool for high-temperature applications.

The durability of a muffle furnace comes from its robust physical construction, while its efficiency stems from a sophisticated system of thermal insulation and intelligent power management. These two aspects work together to create a reliable, long-lasting instrument with low operational costs.

The Foundation of Durability: Robust Construction and Materials

The long-term reliability of a muffle furnace is not an accident; it is the direct result of specific choices in materials and structural design.

High-Quality, Heat-Resistant Components

Muffle furnaces are built with premium, heat-resistant materials designed for demanding environments. The housing is often made of textured stainless steel sheets, providing a sturdy and corrosion-resistant exterior.

Purpose-Built for Long-Term Use

These furnaces are engineered for continuous, long-term operation. The emphasis on extra sturdy construction ensures they can withstand the thermal stress of repeated heating and cooling cycles without degradation.

Cross-Industry Validation

The versatility of muffle furnaces across demanding sectors like glass manufacturing, metal heat treatment, and cement production serves as proof of their robustness. Equipment proven in these heavy industries is more than capable of meeting the precision and durability standards required in laboratory or pharmaceutical settings.

The Mechanics of Efficiency: How Heat is Managed

Efficiency in a muffle furnace is about generating heat effectively and, more importantly, keeping it where it belongs. Every design feature is aimed at maximizing thermal performance and minimizing wasted energy.

Advanced Insulation is Key

The most significant factor in efficiency is insulation. Modern furnaces use advanced ceramic fiber insulation within their walls and doors. This material is exceptionally effective at preventing heat from escaping, which directly reduces power consumption.

High-Performance Heating Elements

The heating elements themselves are chosen for thermal efficiency. Materials like silicon carbide offer excellent thermal conductivity, meaning they transfer heat to the chamber quickly and effectively, reducing the time and energy needed to reach the target temperature.

Intelligent Power Management

Modern furnaces rarely operate at 100% power. They feature fully programmable controls that intelligently adjust power output. Once a set temperature is reached, the system reduces power or cycles on and off to maintain stability, preventing energy waste.

Optimized Heating and Cooling Rates

Efficiency is also gained by tailoring the process to the need. The ability to program specific heating and cooling rates allows operators to use only the energy required for a particular experiment, avoiding the waste associated with a one-size-fits-all approach.

Understanding the Trade-offs and Considerations

While highly effective, selecting a muffle furnace requires understanding the relationship between features, cost, and application.

Initial Cost vs. Long-Term Value

The use of premium materials, advanced insulation, and sophisticated control systems means a muffle furnace can represent a significant upfront investment. This initial cost is offset by lower operational costs over the equipment's lifespan due to reduced energy consumption and superior durability.

The Role of Specialized Components

Features like vacuum capabilities or Mass Flow Controllers (MFC) can dramatically increase sample throughput and processing efficiency. However, these add complexity and cost, and are only beneficial for specific, high-volume applications.

Matching the Furnace to the Task

A furnace's efficiency is directly tied to its use. An oversized furnace used for a small sample will be inherently inefficient, as it requires more energy to heat the larger empty space. Proper sizing is critical to realizing the full benefits of the design.

Making the Right Choice for Your Application

Understanding the principles of durability and efficiency allows you to select a furnace that aligns perfectly with your primary goal.

- If your primary focus is maximum durability and longevity: Look for models with stainless steel construction, premium components, and a proven track record in heavy industrial applications.

- If your primary focus is minimizing operational costs: Prioritize models with thick ceramic fiber insulation, well-sealed doors, and intelligent, programmable power controls.

- If your primary focus is high-throughput processing: Consider specialized models, such as those with vacuum capabilities, that are designed to minimize processing time per sample.

By aligning the furnace's features with your specific needs, you transform it from a simple piece of equipment into a strategic, long-term asset.

Summary Table:

| Aspect | Durability Features | Efficiency Features |

|---|---|---|

| Materials | Textured stainless steel, heat-resistant components | Silicon carbide heating elements |

| Design | Extra sturdy construction, corrosion-resistant | Advanced ceramic fiber insulation |

| Performance | Long-term reliability, cross-industry validation | Programmable controls, optimized heating/cooling rates |

| Benefits | Withstands thermal stress, versatile applications | Reduced power consumption, lower operational costs |

Ready to enhance your lab's performance with a durable and efficient muffle furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for improved efficiency and longevity. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis