In materials research, hot press furnaces are important because they provide a unique capability: the simultaneous application of extreme temperature and high pressure in a precisely controlled environment. This combination allows scientists to force materials into new structures and states that would otherwise be impossible to achieve, enabling the creation of advanced materials with superior properties like enhanced density, strength, and thermal stability.

A hot press furnace is more than just an oven; it is a tool for directed material design. Its true importance lies in giving researchers precise, simultaneous control over heat, pressure, and atmosphere, which is the key to manipulating atomic arrangements and fabricating next-generation materials.

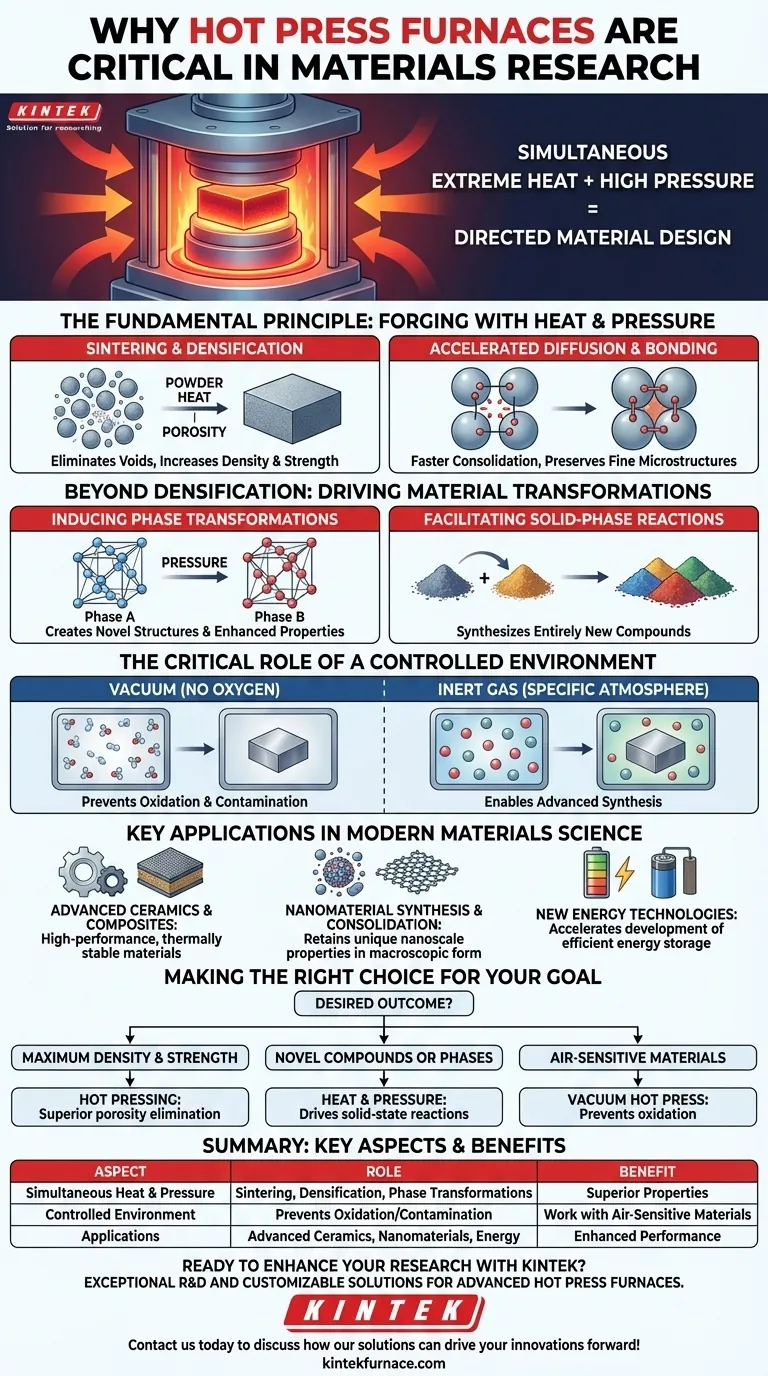

The Fundamental Principle: Forging Materials with Heat and Pressure

At its core, a hot press furnace solves a fundamental problem in materials science: how to consolidate powders into a solid, dense object without melting them. This process, known as sintering, is dramatically enhanced by the addition of pressure.

Eliminating Porosity for Maximum Density

When materials are heated, their atoms become more mobile. Applying external pressure physically forces the individual grains or particles together, closing the gaps and voids (porosity) between them.

This results in a final product that is significantly denser and less porous than one created by heating alone, which is critical for applications requiring high mechanical strength or specific optical properties.

Accelerating Diffusion and Bonding

Heat provides the energy for atoms to diffuse across the boundaries of touching particles, forming strong chemical bonds. Pressure increases the contact area between these particles and lowers the energy required for this diffusion to occur.

The synergy between heat and pressure dramatically speeds up the entire consolidation process, often allowing for lower processing temperatures and shorter times, which can prevent unwanted grain growth and preserve fine microstructures.

Beyond Densification: Driving Material Transformations

While creating dense parts is a primary function, the true power of a hot press furnace lies in its ability to drive fundamental changes within the material itself.

Inducing Phase Transformations

Many materials can exist in different atomic arrangements, or phases, each with unique properties. By carefully controlling temperature and pressure, researchers can force a material to transform from one phase to another, creating novel structures with enhanced characteristics.

Facilitating Solid-Phase Reactions

A hot press can be used to synthesize entirely new compounds by pressing and heating a mixture of different powders. The intimate contact and high energy provided by the process drive a solid-state reaction, forming a new, unified material from the constituent parts.

The Critical Role of a Controlled Environment

The ability to manipulate the atmosphere inside the furnace is just as important as controlling temperature and pressure. Modern hot press furnaces often operate under a vacuum or are backfilled with a specific inert gas.

Preventing Oxidation and Contamination

Operating under a vacuum removes oxygen and other reactive gases. This is essential when working with metals and certain ceramics that would otherwise oxidize and degrade at high temperatures, compromising the final material's integrity.

Enabling Advanced Synthesis

For some processes, a specific atmosphere is required. The furnace can be filled with an inert gas like argon to prevent reactions or even a reactive gas to participate in the material's synthesis, offering another layer of control for the researcher.

Key Applications in Modern Materials Science

The unique capabilities of hot pressing make it indispensable for developing materials at the cutting edge of technology.

Advanced Ceramics and Composites

Hot pressing is a standard method for producing high-performance technical ceramics and ceramic matrix composites (CMCs). These materials offer exceptional hardness and stability at extreme temperatures but are difficult to densify without pressure.

Nanomaterial Synthesis and Consolidation

For nanomaterials like graphene, hot pressing provides a way to consolidate nanoscale powders into macroscopic objects while retaining their unique nanoscale properties, a significant challenge in the field of nanotechnology.

New Energy Technologies

In battery research, these furnaces are used to synthesize novel electrode materials and test their performance under simulated operating conditions. This helps accelerate the development of more efficient and durable energy storage solutions.

Making the Right Choice for Your Goal

Using a hot press furnace is a strategic decision based on the desired outcome for the material.

- If your primary focus is achieving maximum density and strength: Hot pressing is the superior method for eliminating porosity and creating mechanically robust components from powders.

- If your primary focus is creating novel compounds or phases: The combination of heat and pressure is a powerful tool for driving solid-state reactions and phase transformations that are not thermodynamically favorable under normal conditions.

- If your primary focus is working with air-sensitive materials: A vacuum hot press is essential for preventing oxidation and contamination during high-temperature processing.

Ultimately, the hot press furnace is a foundational tool that empowers researchers to build materials from the ground up, moving beyond simply observing properties to actively designing them.

Summary Table:

| Key Aspect | Role in Materials Research |

|---|---|

| Simultaneous Heat & Pressure | Enables sintering, densification, and phase transformations for superior material properties. |

| Controlled Environment | Prevents oxidation and contamination, allowing work with air-sensitive materials under vacuum or inert gas. |

| Applications | Used in advanced ceramics, nanomaterials, composites, and energy technologies for enhanced performance. |

| Benefits | Accelerates diffusion, reduces processing times, and facilitates solid-phase reactions for innovative material design. |

Ready to enhance your materials research with precise high-temperature and high-pressure solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced hot press furnaces, including customizable options for vacuum and atmosphere control. Our expertise in sintering, phase transformations, and nanomaterial synthesis ensures tailored solutions for your unique experimental needs. Contact us today to discuss how our high-temperature furnace solutions can drive your innovations forward!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is a vacuum hot press furnace? Unlock Superior Material Performance