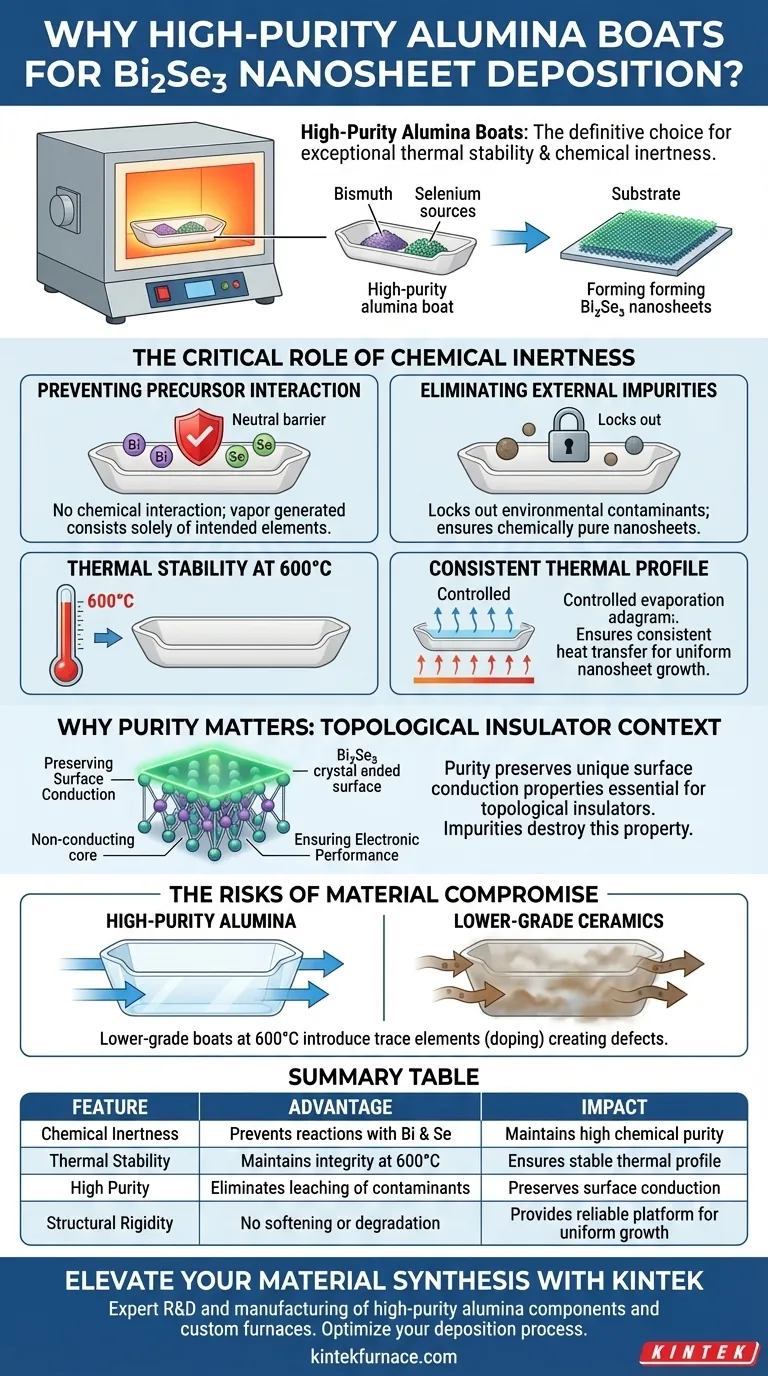

High-purity alumina boats are the definitive choice for the deposition of bismuth selenide (Bi2Se3) nanosheets due to their exceptional thermal stability and chemical inertness. Even at the required reaction temperatures of 600°C, these containers refuse to react with bismuth or selenium raw materials, ensuring the precursors remain uncontaminated.

Core Insight: The selection of alumina is not merely about holding the material; it is about preserving the delicate physics of the final product. By preventing chemical reactions at high heat, alumina protects the purity required to maintain the essential surface conduction characteristics of topological insulators.

The Critical Role of Chemical Inertness

Preventing Precursor Interaction

During the evaporation process, bismuth and selenium are subjected to intense heat.

High-purity alumina acts as a neutral barrier. It does not chemically interact with the raw materials, ensuring that the vapor generated consists solely of the intended elements.

Eliminating External Impurities

Any reaction between the container and the source material introduces foreign atoms into the crystal lattice.

By using high-purity alumina, you effectively lock out environmental contaminants. This ensures that the synthesized nanosheets are chemically pure, which is the baseline requirement for high-quality semiconductor growth.

Thermal Stability at 600°C

Withstanding Reaction Conditions

The synthesis of Bi2Se3 nanosheets requires a specific high-temperature environment to facilitate proper evaporation and deposition.

Alumina boats maintain their structural integrity at 600°C. They do not soften, outgas, or degrade, providing a stable platform throughout the duration of the thermal cycle.

Consistent Thermal Profile

Because the boat remains stable, it ensures consistent heat transfer to the raw materials.

This stability allows for a controlled evaporation rate, which is necessary for growing uniform nanosheets rather than irregular bulk clusters.

Why Purity Matters: The Topological Insulator Context

Preserving Surface Conduction

Bismuth selenide is prized because it is a topological insulator—a material that conducts electricity on its surface but behaves as an insulator in its interior.

Impurities destroy this property. If the container leaches contaminants into the material, the unique surface conduction characteristics can be lost or heavily degraded.

Ensuring Electronic Performance

For researchers and engineers, the goal is to measure or utilize these exotic electronic states.

High-purity alumina ensures that the measured properties are intrinsic to the Bi2Se3, rather than artifacts caused by container-induced pollution.

The Risks of Material Compromise

The Dangers of Lower-Grade Ceramics

Not all ceramic boats are created equal. Using standard ceramics or lower-purity alumina can be a critical error in this specific application.

At 600°C, trace elements in lower-grade boats can diffuse into the bismuth or selenium melt. This unintentional "doping" creates defects in the nanosheets that render them useless for topological applications.

Making the Right Choice for Your Goal

To ensure the success of your deposition process, align your equipment choices with your experimental objectives.

- If your primary focus is synthesizing topological insulators: Prioritize high-purity alumina to strictly prevent contamination and preserve surface conduction states.

- If your primary focus is basic thermal testing: Ensure your container is rated for at least 600°C, but understand that lower-purity options may alter the chemical composition of the sample.

Ultimately, the chemical inertness of the boat is just as critical as the purity of the source materials themselves.

Summary Table:

| Feature | Advantage for Bi2Se3 Deposition | Impact on Final Product |

|---|---|---|

| Chemical Inertness | Prevents reactions with Bi and Se precursors | Maintains high chemical purity of nanosheets |

| Thermal Stability | Maintains integrity at 600°C without outgassing | Ensures a stable and consistent thermal profile |

| High Purity | Eliminates leaching of external contaminants | Preserves unique surface conduction properties |

| Structural Rigidity | No softening or degradation during cycles | Provides a reliable platform for uniform growth |

Elevate Your Material Synthesis with KINTEK

Precision in Bi2Se3 nanosheet growth requires more than just high-quality precursors—it demands the right environment. Backed by expert R&D and manufacturing, KINTEK offers high-purity alumina components alongside our Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab equipment or a customizable high-temp furnace tailored to your unique research needs, we provide the stability and purity your experiments deserve.

Ready to optimize your deposition process? Contact KINTEK today to discuss your custom furnace and labware requirements.

Visual Guide

References

- Chih-Chiang Wang, He-Ting Tsai. Enhanced electrical properties of amorphous In-Sn-Zn oxides through heterostructuring with Bi2Se3 topological insulators. DOI: 10.1038/s41598-023-50809-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How are constant temperature water baths and drying ovens utilized to verify bonding quality? Master EN 314-1 Testing

- How does a high-precision vacuum pump reduce reaction temperatures in zinc extraction? Optimize Your Energy Efficiency

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- What is the function of a forced air drying oven in zeolite preparation? Protect Pore Integrity and Ensure Uniformity

- What accessories are used with silicon carbide heating elements and their functions? Ensure Reliable Performance and Longevity

- Why use graphite or quartz crucibles for liquid antimony-tellurium? Protect Your High-Temp Melt Integrity