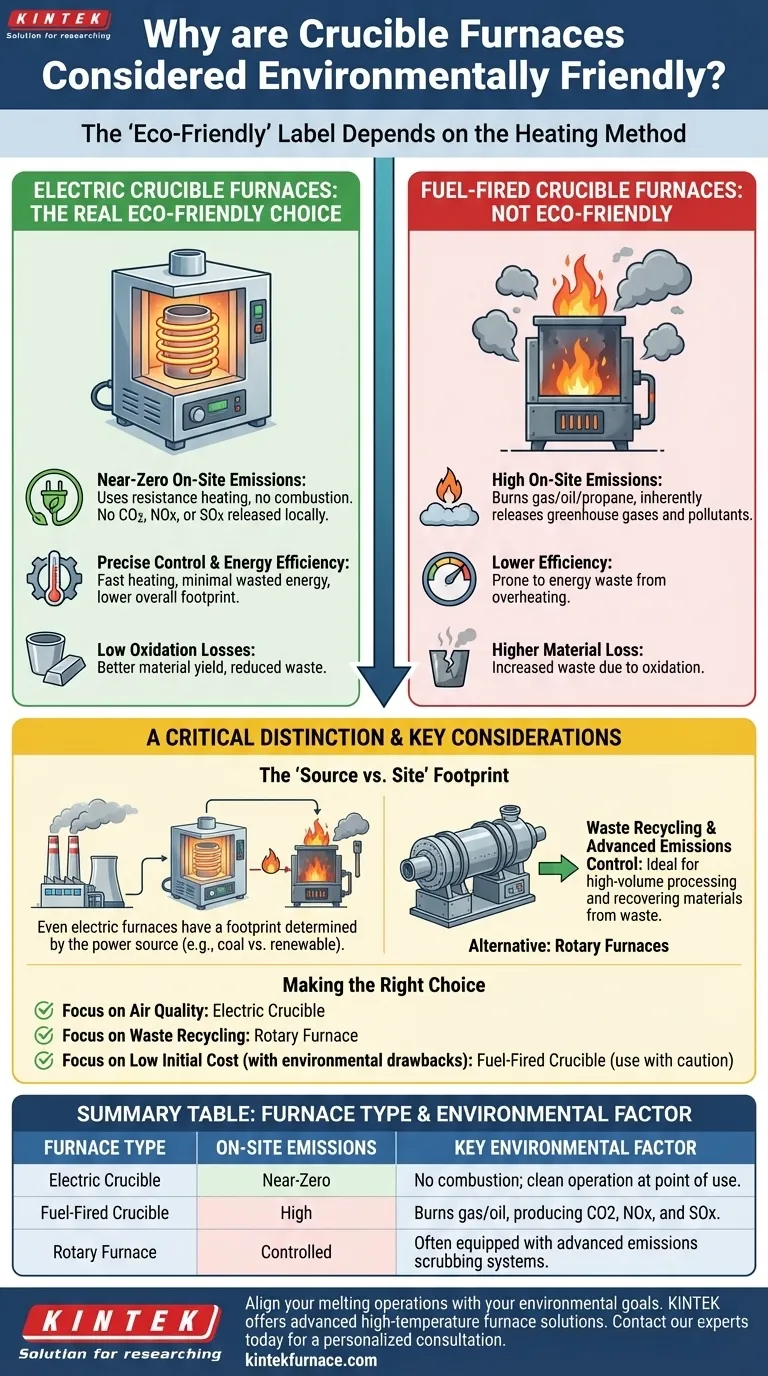

At its core, the environmental reputation of a crucible furnace is almost entirely dependent on its heating method. While they can be exceptionally clean, this advantage is specific to electric models, which produce virtually no emissions at the point of use. Traditional fuel-fired crucible furnaces, by contrast, can produce significant emissions.

The "eco-friendly" label for crucible furnaces is a crucial oversimplification. The reality is that only electric crucible furnaces minimize on-site environmental impact, while their fuel-fired counterparts do not.

The Source of the "Eco-Friendly" Claim: Electric Heating

The argument for crucible furnaces being environmentally friendly is centered on modern electric designs. These models offer distinct advantages over furnaces that rely on the combustion of fossil fuels.

Electric Furnaces: Near-Zero Local Emissions

An electric crucible furnace operates much like an electric stove, using resistance heating elements to generate thermal energy.

Because this process involves no combustion, it produces none of the typical harmful byproducts like carbon dioxide (CO2), nitrogen oxides (NOx), or sulfur oxides (SOx) on-site. This makes them ideal for operations in areas with stringent air quality regulations.

Precise Control and Energy Efficiency

Modern graphite crucibles, often used in electric furnaces, allow for very fast heating and precise temperature control.

This precision minimizes the energy wasted by overshooting or maintaining unnecessarily high temperatures. Better energy efficiency translates directly to a smaller overall environmental footprint, as less power is consumed for the same amount of work.

A Critical Distinction: Fuel-Fired vs. Electric

It is a mistake to assume all crucible furnaces are environmentally friendly. The heating source is the single most important factor, and traditional models present a completely different environmental profile.

The Reality of Traditional Furnaces

Fuel-fired crucible furnaces, which burn natural gas, oil, or propane, can produce high levels of emissions. The combustion process inherently releases greenhouse gases and other pollutants into the atmosphere.

While they may be cheaper to operate in some regions, they are not a suitable choice for any application where minimizing environmental impact is a priority.

The "Source vs. Site" Footprint

It is important to recognize that even an electric furnace has an environmental footprint determined by its power source.

If the electricity is generated by a coal-fired power plant, the emissions are simply moved from the furnace site to the power plant. A truly "green" operation pairs an electric furnace with electricity from renewable sources like solar, wind, or hydropower.

Understanding the Trade-offs and Alternatives

Choosing a furnace requires balancing environmental goals with operational and financial realities. Crucible furnaces are not the only option, and it's wise to understand their position relative to other technologies.

Key Trade-off: Cost and Material Purity

Electric furnaces often have a higher initial cost and can be more expensive to operate depending on local electricity prices.

However, they also tend to produce low oxidation losses. This means less of the metal is lost to slag during melting, which improves material yield and reduces waste—an indirect but significant environmental and financial benefit.

Comparing to Other Technologies: Rotary Furnaces

For certain applications, especially those involving waste recycling, a rotary furnace can be a more environmentally sound choice.

These furnaces are often equipped with advanced emissions control systems and are highly efficient at recovering valuable materials from industrial waste. They are designed for high-volume processing and can even handle hazardous materials safely.

Making the Right Choice for Your Operation

Your decision should be guided by your primary operational goal. There is no single "best" furnace, only the right tool for a specific job.

- If your primary focus is minimizing on-site emissions for air quality: An electric crucible furnace is the clear choice due to its near-zero local emissions profile.

- If your primary focus is processing industrial waste or requiring advanced emission controls: A rotary furnace is likely a better-suited and more environmentally robust alternative.

- If your primary focus is the lowest initial investment for a small-scale foundry: A fuel-fired crucible furnace might be considered, but only with a full understanding of its significant environmental drawbacks.

Ultimately, understanding the distinction between heating sources empowers you to see past marketing claims and select a technology that truly aligns with your environmental and operational goals.

Summary Table:

| Furnace Type | On-Site Emissions | Key Environmental Factor |

|---|---|---|

| Electric Crucible | Near-Zero | No combustion; clean operation at point of use. |

| Fuel-Fired Crucible | High | Burns gas/oil, producing CO2, NOx, and SOx. |

| Rotary Furnace | Controlled | Often equipped with advanced emissions scrubbing systems. |

Align your melting operations with your environmental goals. At KINTEK, we understand that the right furnace technology is critical for both performance and sustainability. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Whether you need the clean operation of an electric crucible furnace or the robust processing capabilities of a rotary furnace for waste recycling, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capability to precisely meet your unique requirements.

Let's find the most efficient and eco-conscious solution for your lab. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide