At its core, a rotary kiln is a highly versatile thermal reactor capable of facilitating a wide range of chemical and physical transformations. The primary reaction types include calcination, sintering, thermal desorption, reduction roasting, and incineration. These processes are not mutually exclusive and often occur in sequence within the kiln to convert raw feed materials into a desired final product.

A rotary kiln is best understood not by a single reaction, but by its ability to execute a sequence of thermal transformations with exceptional uniformity. Its defining feature—the continuous tumbling of material—ensures every particle receives consistent heat treatment, which is the key to producing a homogenous, high-quality output at an industrial scale.

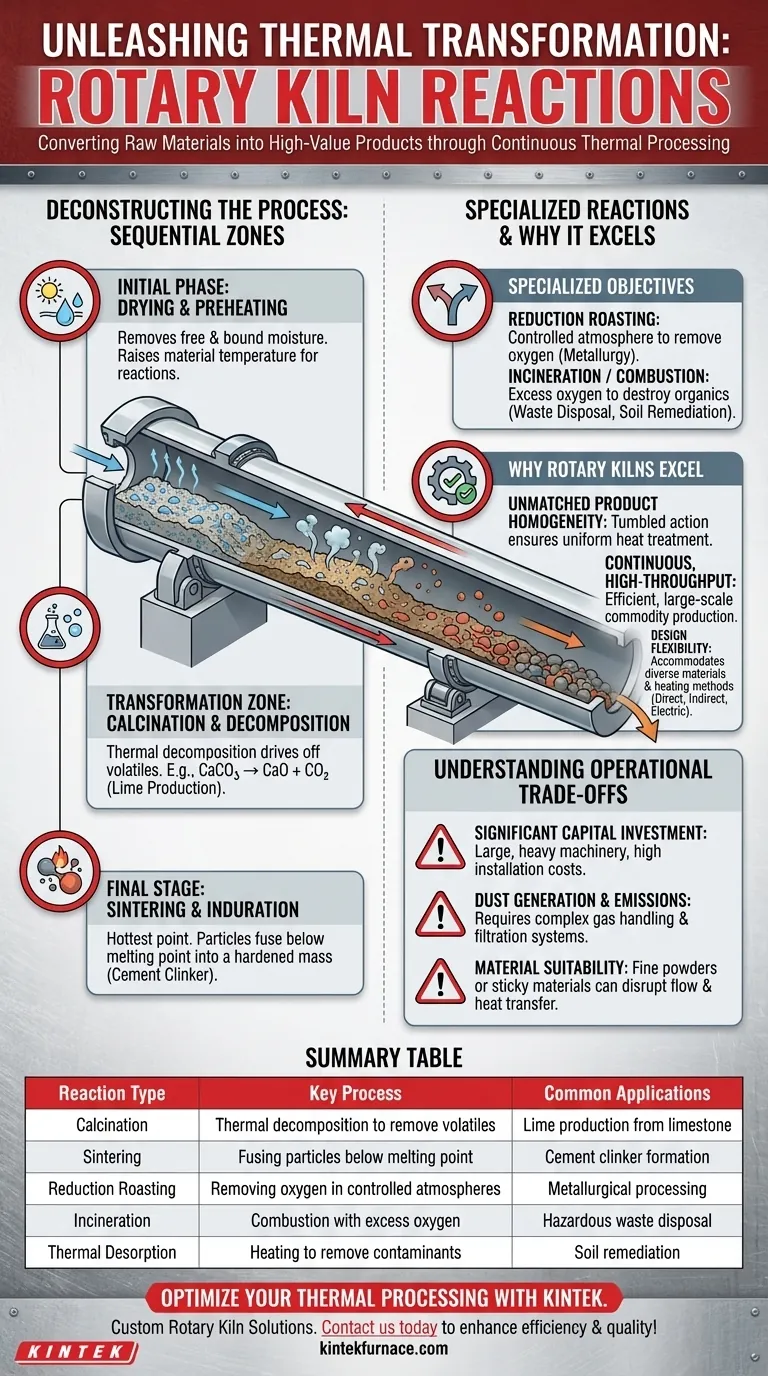

Deconstructing the Thermal Process

The power of a rotary kiln lies in its ability to create different temperature zones along its length, allowing materials to undergo a series of changes in a single, continuous pass.

The Initial Phase: Drying and Preheating

Before any chemical reaction can occur, free and bound moisture must be removed. As material enters the kiln, the initial zone is dedicated to drying and raising the material's temperature to the point where the primary reactions can begin.

The Transformation Zone: Calcination and Decomposition

Calcination is one of the most common reactions in a rotary kiln. It is a thermal decomposition process that drives off a volatile component from a solid.

A classic example is the production of lime from limestone, where high heat drives off carbon dioxide (CO2) from calcium carbonate (CaCO3) to produce calcium oxide (CaO).

The Final Stage: Sintering and Induration

Sintering, or induration, occurs at the hottest point in the kiln. This process heats materials to just below their melting point, causing individual particles to fuse together into a single, hardened mass.

This is the critical reaction in cement production, where a precise mix of raw materials is sintered to form "clinker," the foundational component of cement.

Specialized Reactions: Roasting and Combustion

Rotary kilns are also used for more specific chemical objectives. Reduction roasting uses a controlled atmosphere to remove oxygen from metal oxides, a key step in many metallurgical circuits.

Conversely, incineration and organic combustion use excess oxygen to completely destroy organic compounds, making kilns essential for hazardous waste disposal and soil remediation.

Why a Rotary Kiln Excels at These Reactions

The design of a rotary kiln is uniquely suited to performing these thermal tasks efficiently and consistently at a large scale.

Unmatched Product Homogeneity

The slow, constant rotation of the kiln shell continuously tumbles the material bed. This mixing action eliminates hot spots and ensures that every particle is exposed to the same temperature profile, resulting in a highly uniform and consistent final product.

Continuous, High-Throughput Processing

Unlike batch furnaces, rotary kilns operate continuously. Raw material is constantly fed into one end while the finished product is discharged from the other, enabling enormous throughput rates essential for commodity production.

Design and Process Flexibility

Kilns can be engineered to accommodate a vast range of materials and process requirements. They can be heated directly with a flame or indirectly, and even utilize electric heating for specialized applications in the chemical and non-ferrous metals industries.

Understanding the Operational Trade-offs

While powerful, a rotary kiln is not the universal solution for all thermal processing. Understanding its limitations is critical for proper application.

Significant Capital Investment

Rotary kilns are large, heavy-duty pieces of industrial machinery. The initial capital cost, along with the expense of foundation work and installation, is substantial and must be justified by high-volume production.

Dust Generation and Emissions Control

The tumbling action that ensures homogeneity also inherently creates dust. Consequently, all rotary kiln systems require sophisticated gas handling and filtration systems to capture particulate matter and control emissions, adding to their complexity and cost.

Material Suitability

The process relies on material flowing and tumbling correctly. Extremely fine, light powders may become entrained in the process gas, while sticky or viscous materials can form clumps and coatings on the kiln wall, disrupting flow and heat transfer.

Making the Right Choice for Your Goal

Selecting the correct process configuration depends entirely on your desired outcome.

- If your primary focus is producing a mineral commodity like lime or cement: You will rely on calcination and sintering to chemically and physically transform raw feed into a new, hardened product.

- If your primary focus is environmental remediation: Your process will center on thermal desorption or incineration to reliably destroy organic contaminants in soil or waste.

- If your primary focus is metallurgical processing: You will likely use reduction roasting in a controlled atmosphere to chemically prepare metal oxides for subsequent steps.

- If your primary focus is creating lightweight construction aggregates: You will use rapid heat setting and induration to expand and harden materials like clay or shale.

Understanding these core reaction types allows you to leverage the rotary kiln not just as a piece of equipment, but as a precise tool for material transformation.

Summary Table:

| Reaction Type | Key Process | Common Applications |

|---|---|---|

| Calcination | Thermal decomposition to remove volatiles | Lime production from limestone |

| Sintering | Fusing particles below melting point | Cement clinker formation |

| Reduction Roasting | Removing oxygen in controlled atmospheres | Metallurgical processing |

| Incineration | Combustion with excess oxygen | Hazardous waste disposal |

| Thermal Desorption | Heating to remove contaminants | Soil remediation |

Ready to optimize your thermal processing with a custom rotary kiln solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental and industrial requirements. Contact us today to discuss how we can enhance your efficiency and product quality!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries