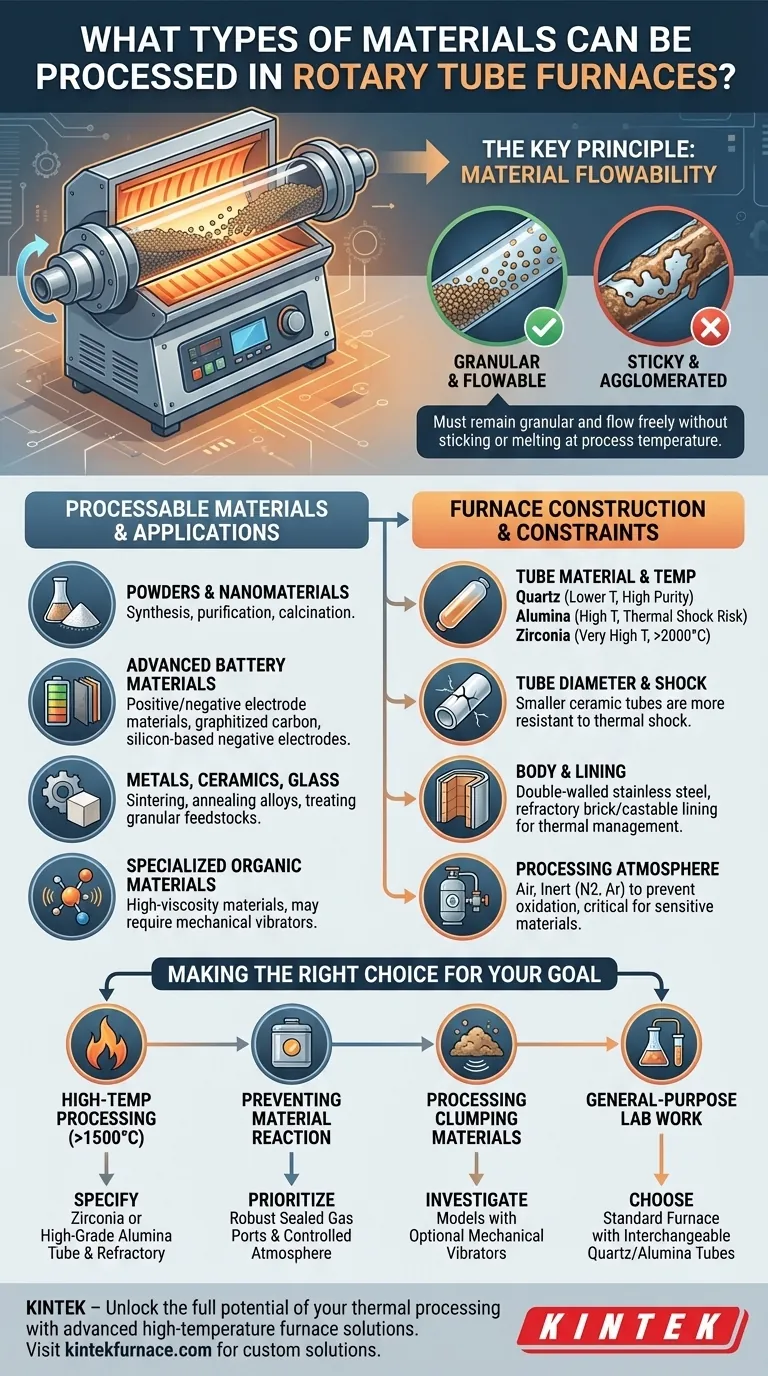

At a fundamental level, rotary tube furnaces can process a wide variety of granular, particulate, and powdered materials. This includes diverse categories such as metal powders, nanomaterials, ceramics, optical materials, and specific chemical compounds like positive and negative battery electrode materials. The key is that the material must be able to tumble and flow freely during the heating process.

The suitability of a material for a rotary tube furnace is defined less by its chemical type and more by its physical behavior. The core requirement is that the material must remain granular and flowable at the target processing temperature without sticking, melting, or agglomerating.

The Defining Principle: Material Flowability

The continuous rotation of the furnace tube is what ensures uniform heating. This mechanism only works if the material inside can move properly.

What Makes a Material Suitable?

A material is ideal for a rotary tube furnace if it is granular or particulate. This physical form allows the particles to tumble and mix as the tube rotates, exposing all surfaces to the heat source and process atmosphere.

This constant motion is crucial for achieving batch homogeneity in processes like calcination, pyrolysis, and chemical vapor deposition (CVD).

The Critical Constraint: Stickiness and Agglomeration

Materials that become sticky, viscous, or begin to melt at elevated temperatures are not suitable for standard rotary tube furnaces.

This stickiness causes the material to coat the inside of the tube wall instead of tumbling. It leads to non-uniform heating, potential damage to the tube, and makes removal of the processed material extremely difficult.

The Role of Processing Atmosphere

Most processes are conducted in either air or an inert atmosphere (like nitrogen or argon) to prevent undesirable oxidation or other chemical reactions.

Modern furnaces often include dedicated gas ports to allow for a controlled environment, which is critical when processing sensitive materials like battery components or specific metal alloys.

Common Material Categories and Applications

While flowability is the guiding rule, these furnaces are used across many industries with specific material types.

Powders and Nanomaterials

This is the broadest category, encompassing everything from bulk chemical powders to advanced nanomaterials. The furnace provides the controlled thermal treatment necessary for synthesis, purification, or modification.

Advanced Battery Materials

The new energy sector relies heavily on these furnaces. They are used to process positive/negative electrode materials, graphitized carbon, and silicon-based negative electrode materials, which require precise thermal treatment in controlled atmospheres.

Metals, Ceramics, and Glass

In metallurgy and materials science, rotary kilns and tube furnaces are used for a range of applications. They can process metal powders for sintering, anneal alloys, and treat granular ceramics or glass feedstocks.

Specialized Organic Materials

While many organics become sticky, some high-viscosity organic materials can be processed. This often requires furnaces with optional modifications like a hammer vibrator to dislodge material from the tube walls or heated jackets to prevent tar condensation.

Understanding the Trade-offs: Furnace Construction vs. Material

The material you need to process directly dictates the required construction of the furnace. Mismatches lead to process failure or equipment damage.

Tube Material and Temperature Limits

The rotating process tube is the most critical component. Its material determines the maximum operating temperature.

- Quartz: Used for lower-temperature applications and when high purity is essential.

- Alumina: A common choice for high-temperature work, but it is susceptible to thermal shock (cracking from rapid temperature changes).

- Zirconia: Required for very high-temperature operations, such as those approaching 3600°F (approx. 2000°C).

- High-Temperature Alloys: Offer better resistance to thermal shock than ceramics but may have lower maximum temperature ceilings.

Tube Diameter and Thermal Shock

For ceramic tubes like alumina, smaller diameters are more resistant to thermal shock. Rapid heating or cooling of a large-diameter ceramic tube creates significant thermal stress, increasing the risk of fracture.

Furnace Body and Refractory Lining

The furnace body is typically made of double-walled stainless steel for durability and insulation. The internal refractory lining is also key for thermal management and can consist of durable bricks, castable cement, or moldable materials for complex shapes.

Making the Right Choice for Your Goal

To select the right configuration, you must match the furnace's capabilities to your material's properties and your process requirements.

- If your primary focus is high-temperature processing (>1500°C): You must specify a furnace with a zirconia or high-grade alumina tube and corresponding refractory linings.

- If your primary focus is preventing material reaction: Prioritize a system with robust, sealed gas ports for creating a controlled inert atmosphere.

- If your primary focus is processing materials prone to clumping: Investigate models that offer optional features like mechanical vibrators to ensure material flow.

- If your primary focus is general-purpose lab work: A standard furnace with interchangeable quartz and alumina tubes provides the most operational flexibility for a range of materials and temperatures.

By aligning the physical properties of your material with the furnace's mechanical and thermal capabilities, you ensure a successful and efficient process.

Summary Table:

| Material Type | Key Characteristics | Common Applications |

|---|---|---|

| Powders & Nanomaterials | Granular, flowable | Synthesis, purification, calcination |

| Battery Materials | Electrode materials, graphitized carbon | Thermal treatment in controlled atmospheres |

| Metals & Ceramics | Sintering, annealing | Metallurgy, materials science |

| Specialized Organics | High-viscosity, may require modifications | Processing with vibrators or heated jackets |

Unlock the full potential of your thermal processing with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with powders, nanomaterials, or battery components, our expertise ensures uniform heating, controlled atmospheres, and enhanced efficiency. Contact us today to discuss how we can tailor a solution for your specific material processing challenges!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules