In short, a box furnace can handle a wide range of materials, making it a cornerstone tool in many industries. The most common categories include metals, alloys, and ceramics, but their suitability extends to glass, certain plastics, and other advanced materials depending on the furnace's specific configuration.

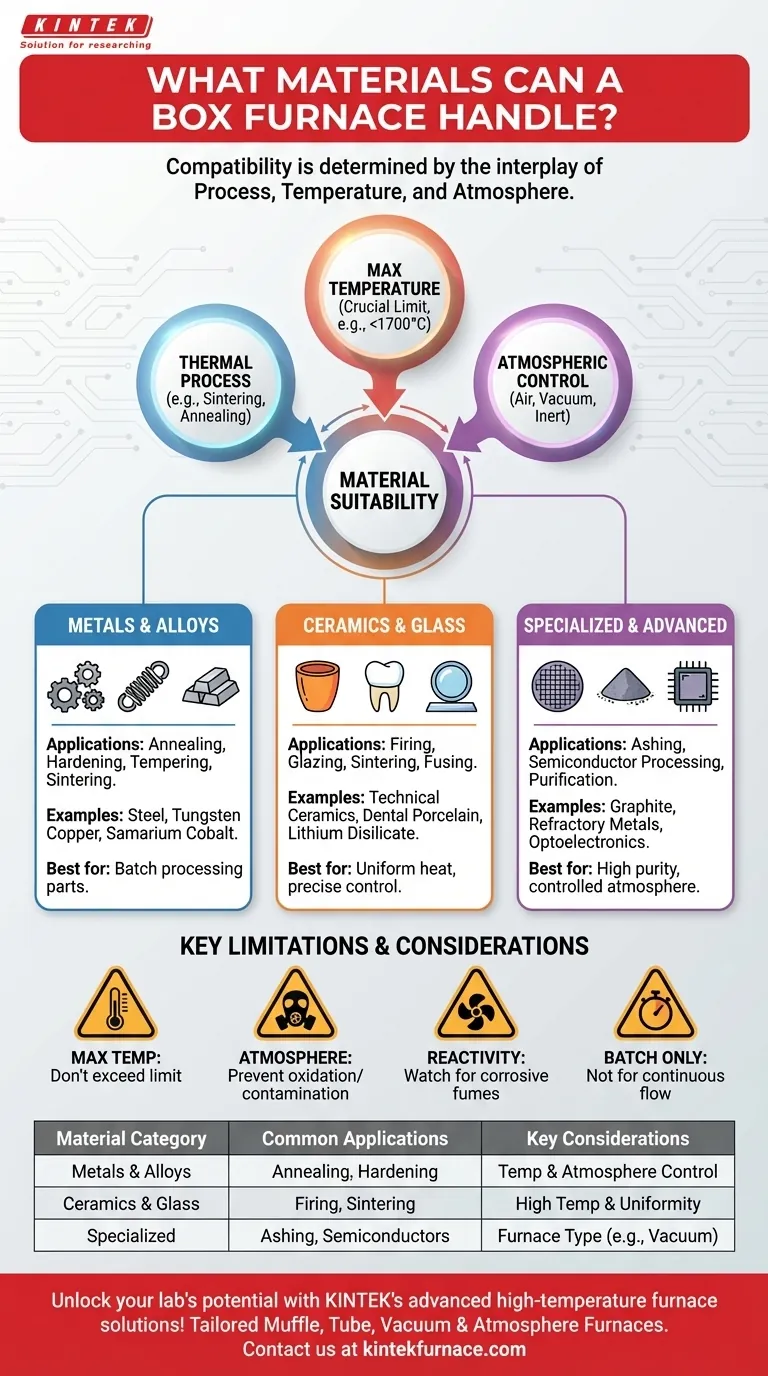

A box furnace's material compatibility is not defined by a simple list. Instead, it is determined by the interplay between the furnace's maximum temperature, its atmospheric control capabilities, and the specific thermal process you need to perform.

The Principle Behind Material Compatibility

To understand what a box furnace can handle, you must first understand the factors that govern its operation. The choice of material is secondary to the requirements of the process.

It's About the Process, Not Just the Material

A box furnace doesn't just "heat things up." It is a precise instrument for executing thermal processes that alter a material's physical or chemical properties.

These processes include heat treatment (like annealing or hardening metals), sintering (fusing ceramic or metal powders together), alloying (melting and mixing metals), and burn-off or ashing (for environmental analysis). The material you choose must be compatible with one of these goals.

Temperature as the Primary Limiting Factor

The single most important constraint of a box furnace is its maximum operating temperature. This is dictated by the furnace's own construction materials, particularly its heating elements and internal insulation.

For example, many high-temperature box furnaces use alumina as an insulating material because of its stability and chemical inertness at temperatures up to 1700°C. Any material you process must have a target temperature below this ceiling.

The Role of Atmosphere

A standard box furnace, often called a muffle furnace, operates with a normal air atmosphere. This is perfectly suitable for many applications, like firing basic ceramics or heat treating non-reactive steels.

However, many advanced materials require a specific atmosphere to prevent oxidation or contamination. This is where specialized box furnaces, such as vacuum furnaces or controlled-atmosphere furnaces, become necessary for processing reactive metals, semiconductors, or high-purity compounds.

Common Material Categories and Applications

With the core principles established, we can explore the specific materials commonly processed in various types of box furnaces.

Metals and Alloys

Metals are one of the most common materials used in box furnaces. These furnaces are ideal for the batch processing of steel parts or other metallic components.

Applications include annealing, hardening, tempering, and stress relief. They are also used for sintering powdered metals and creating alloys like tungsten copper or samarium cobalt.

Ceramics and Glass

Ceramics require high temperatures for processes like firing, glazing, and sintering. Box furnaces provide the stable, uniform heat needed to process everything from dental ceramics (lithium disilicate, feldspathic porcelain) to technical ceramics.

Glass can also be processed for annealing, fusing, or slumping, provided the furnace allows for precise temperature control.

Specialized and Organic Materials

More advanced furnace configurations can handle a broader array of materials.

- Muffle furnaces can be used for ashing certain plastics and organic materials for analytical testing.

- Vacuum tube furnaces are critical for processing high-purity materials like semiconductors and optoelectronic coating materials.

- Sintering furnaces can be used for purifying graphite or processing rare refractory metals like tungsten and molybdenum.

Understanding the Trade-offs and Limitations

While versatile, a box furnace is not a universal solution. Understanding its inherent limitations is key to using it effectively and safely.

Maximum Temperature Constraints

Always verify that your material's required processing temperature is well within the furnace's specified maximum. Pushing a furnace beyond its limit can damage the heating elements and insulation, leading to costly repairs and inaccurate results.

Atmospheric Purity

Using a standard air-atmosphere furnace for a material that requires an inert or vacuum environment will likely result in failure. The material will oxidize, become contaminated, or its properties will not develop as intended.

Batch Processing vs. Continuous Flow

Box furnaces are, by definition, batch furnaces. You load a part or a group of parts, run the thermal cycle, and then unload them. This makes them ideal for low-volume production, R&D, or parts requiring long, deep-case heat treatments, but unsuitable for high-volume, continuous manufacturing lines.

Chemical Reactivity

Be cautious of processing materials that could release corrosive fumes or react chemically with the furnace chamber's insulation. Volatile compounds can damage the furnace and pose a safety hazard if not properly ventilated.

Making the Right Choice for Your Material

Your material choice and furnace selection must be guided by your end goal.

- If your primary focus is general-purpose lab work or metal heat treating: A standard muffle-style box furnace is likely sufficient for handling common metals and some ceramics in an air atmosphere.

- If your primary focus is processing reactive metals or high-purity materials: You must use a specialized vacuum furnace or a furnace with inert gas capabilities to prevent oxidation and contamination.

- If your primary focus is advanced ceramics or refractory metals: Select a high-temperature furnace and verify its chamber materials (e.g., alumina) and maximum temperature (e.g., 1700°C) meet the demands of your sintering profile.

Understanding these core principles allows you to select not just a furnace, but the correct thermal processing solution for your specific material goal.

Summary Table:

| Material Category | Common Applications | Key Considerations |

|---|---|---|

| Metals and Alloys | Annealing, hardening, sintering | Requires specific temperature and atmosphere control |

| Ceramics and Glass | Firing, glazing, sintering | Needs high temperatures and uniform heating |

| Specialized Materials | Ashing, semiconductor processing | Depends on furnace type (e.g., vacuum for purity) |

Unlock the full potential of your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're working with metals, ceramics, or advanced materials. Contact us today to discuss how our furnaces can enhance your processes and deliver reliable results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO