In short, customized vacuum furnaces are exceptionally versatile. They are engineered to handle a vast range of materials, from common steels to highly reactive alloys and advanced ceramics. This adaptability extends to a wide spectrum of thermal processes, including fundamental heat treatments like annealing, complex surface modifications like carburizing, and specialized joining techniques like vacuum brazing.

The core value of a customized vacuum furnace lies not in a generic list of capabilities, but in its ability to be precisely designed for a specific material and process. It offers unparalleled control over the processing environment, preventing contamination and ensuring the desired material properties are achieved.

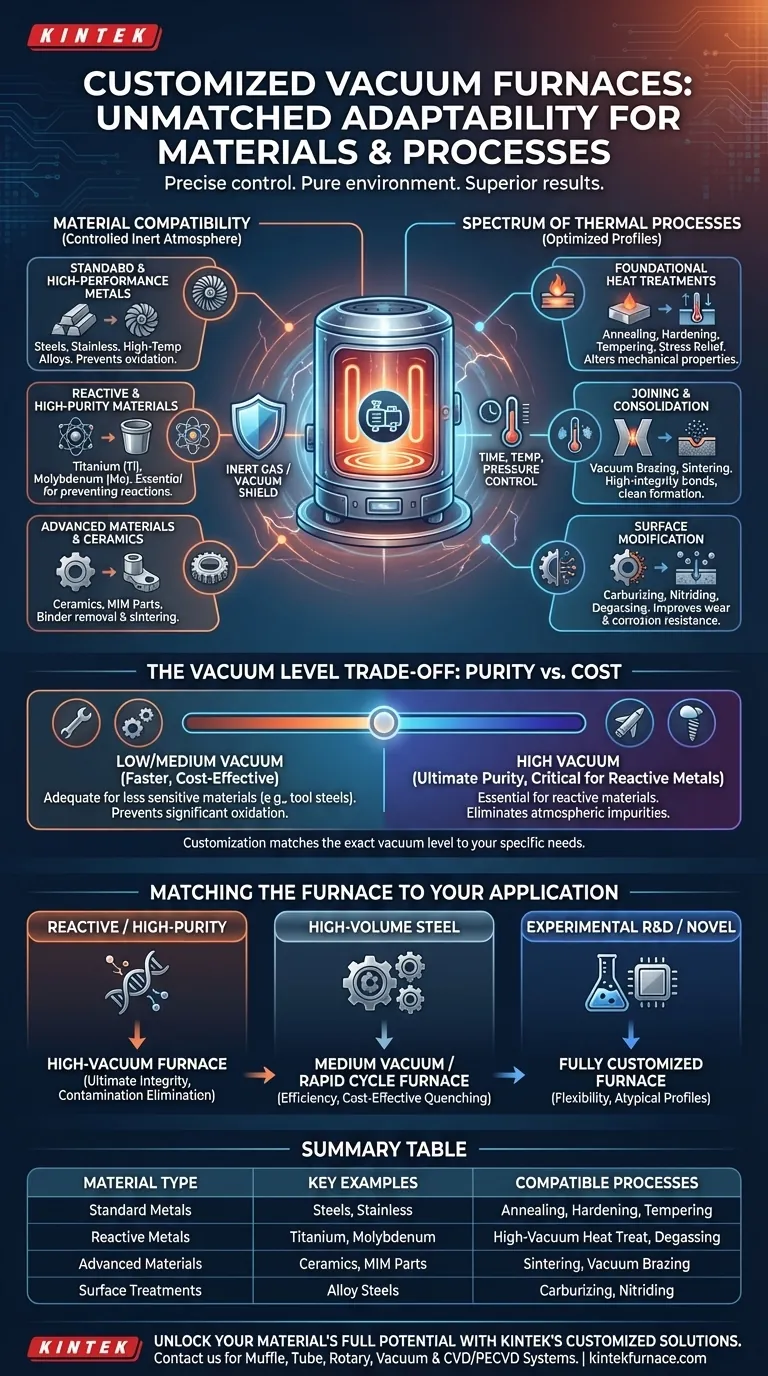

The Scope of Material Compatibility

A vacuum furnace's primary advantage is its ability to create a controlled, inert atmosphere. This makes it suitable for materials that would otherwise react negatively with gases present in the air, such as oxygen.

Standard and High-Performance Metals

Most common industrial metals can be processed in a vacuum furnace. This includes standard steels, stainless steels, and high-temperature alloys used in demanding aerospace and energy applications.

Reactive and High-Purity Materials

This is where vacuum furnaces are indispensable. Materials that are highly reactive with oxygen, nitrogen, or other atmospheric elements at high temperatures must be processed in a vacuum. Key examples include titanium (Ti) and its alloys, as well as refractory metals like molybdenum (Mo).

Advanced Materials and Ceramics

The application of vacuum furnaces extends beyond metals. They are also used for processing certain types of ceramics and for processes like Metal Injection Molding (MIM), where binder is removed and metal powder is sintered into a solid part in a controlled atmosphere.

A Spectrum of Thermal Processes

Customization allows a furnace to be optimized for the specific time, temperature, and pressure profile required by a given process. This enables a broad range of thermal treatments.

Foundational Heat Treatments

These processes aim to alter a material's bulk mechanical properties, such as hardness, ductility, and strength. Common treatments include:

- Annealing: Softening a material to improve machinability or relieve internal stress.

- Hardening (Quenching) & Tempering: Increasing hardness and then reducing brittleness.

- Solutionizing & Aging: A two-step process to strengthen precipitation-hardenable alloys.

- Normalizing & Stress Relief: Refining grain structure and reducing internal stresses.

Joining and Consolidation Processes

Vacuum furnaces are ideal for creating high-integrity bonds and forming solid parts from powders without contamination.

- Vacuum Brazing: Joining components using a filler metal in a clean, flux-free environment, creating strong and clean joints.

- Sintering: Fusing metallic or ceramic powders together below their melting point to form a solid, dense part.

Surface Modification and Chemical Treatments

These processes alter the chemistry of a part's surface to improve wear resistance, hardness, or corrosion resistance.

- Vacuum Carburizing: Introducing carbon into the surface of steel to create a hard outer case.

- Nitriding & Carbonitriding: Diffusing nitrogen (or nitrogen and carbon) into the surface for similar hardening effects.

- Degassing: Removing trapped gases (like hydrogen) from a material to prevent embrittlement.

Understanding the Trade-offs: Process Purity and Cost

The term "vacuum" is not one-size-fits-all. The level of vacuum required is a critical design parameter that directly impacts the furnace's complexity, cost, and suitability for a given application.

The Role of High Vacuum

A high-vacuum environment is essential for processing highly reactive materials like titanium. By removing nearly all atmospheric molecules, it prevents the formation of oxides and other impurities that would compromise the material's structural integrity, purity, and performance.

When Lower Vacuum is Sufficient

For less sensitive materials like common tool steels, a low or medium vacuum is often perfectly adequate. It effectively prevents significant surface oxidation and decarburization during processes like annealing or tempering. Opting for a lower vacuum level can result in a more cost-effective and faster process cycle.

The Customization Advantage

The ability to specify the exact vacuum level, temperature uniformity, chamber size, and quenching system is the primary benefit of a custom furnace. It allows you to build a tool that is perfectly matched to your material's needs and your operational budget, rather than compromising with a standard model.

Matching the Furnace to Your Application

Choosing the right furnace configuration depends entirely on your primary objective.

- If your primary focus is processing reactive or high-purity materials: You need a high-vacuum furnace designed to eliminate atmospheric contamination and ensure ultimate material integrity.

- If your primary focus is high-volume steel treatment: A furnace optimized for medium vacuum, rapid cycle times, and specific quenching requirements will be the most efficient and cost-effective solution.

- If your primary focus is experimental R&D or a novel process: A fully customized furnace is essential to provide the flexibility to control atypical temperature profiles, pressures, and atmospheric compositions.

Ultimately, a customized vacuum furnace empowers you to achieve superior material outcomes by providing precise control over the processing environment.

Summary Table:

| Material Type | Key Examples | Compatible Processes |

|---|---|---|

| Standard Metals | Steels, Stainless Steels | Annealing, Hardening, Tempering |

| Reactive Metals | Titanium, Molybdenum | High-Vacuum Heat Treatment, Degassing |

| Advanced Materials | Ceramics, MIM Parts | Sintering, Vacuum Brazing |

| Surface Treatments | Alloy Steels | Carburizing, Nitriding, Carbonitriding |

Unlock the full potential of your materials with KINTEK's customized vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental requirements are met precisely, enhancing purity, efficiency, and performance. Contact us today to discuss how we can tailor a furnace for your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability