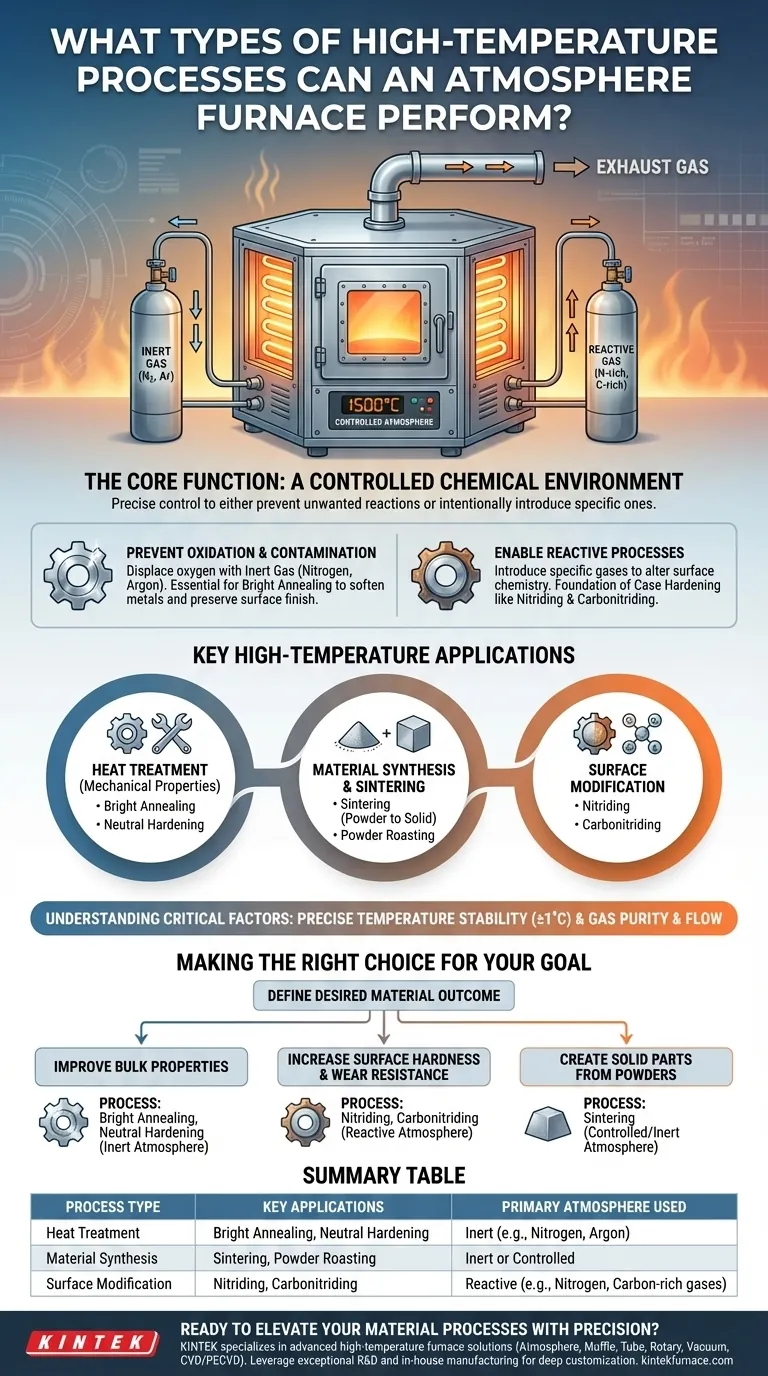

At its core, an atmosphere furnace is a highly versatile tool for material modification, capable of performing a range of high-temperature processes. These include various forms of heat treatment like bright annealing and neutral hardening, material synthesis such as high-temperature sintering, and surface chemistry modification like nitriding and carbonitriding.

The fundamental purpose of an atmosphere furnace is not just to generate heat, but to precisely control the chemical environment around a material. This control allows you to either prevent unwanted reactions like oxidation or intentionally introduce specific reactions to alter a material's properties.

The Core Function: A Controlled Chemical Environment

The "atmosphere" in the furnace's name is the key to its function. By replacing ambient air with a specific gas or mixture of gases, you gain control over the chemical reactions that occur at high temperatures.

Preventing Oxidation and Contamination

Many high-temperature processes fail in the presence of oxygen. The primary role of an inert atmosphere (using gases like nitrogen or argon) is to displace oxygen and prevent oxidation, scaling, and discoloration.

This is essential for bright annealing, where the goal is to soften a metal and relieve internal stresses without creating an oxide layer, thus preserving a clean, bright surface finish.

Enabling Reactive Processes

Beyond prevention, these furnaces can introduce specific reactive gases to intentionally alter the surface chemistry of a material. This is the foundation of case hardening techniques.

For example, nitriding and carbonitriding involve introducing nitrogen-rich (and sometimes carbon-rich) gases. At high temperatures, nitrogen atoms diffuse into the surface of steel, forming extremely hard nitride compounds and creating a wear-resistant "case."

Key High-Temperature Applications

The ability to control both temperature and chemistry unlocks several critical industrial and research processes.

Heat Treatment for Mechanical Properties

Heat treatment modifies a material's microstructure to achieve desired mechanical properties like hardness or ductility.

Neutral hardening is a process used to increase the hardness and strength of steel. It requires a carefully balanced atmosphere to heat the component without adding or removing carbon from its surface, ensuring uniform properties throughout.

Material Synthesis and Sintering

These furnaces are crucial for creating new materials or consolidating them from powder form.

Sintering is the process of taking compacted powder (metal or ceramic) and heating it to just below its melting point. The controlled atmosphere prevents the fine powders from oxidizing and allows the particles to bond together, forming a dense, solid part.

Powder roasting is another common application, used as a preparatory step to induce chemical changes or purify raw material powders before further processing.

Understanding the Critical Factors

Achieving successful and repeatable results depends on more than just choosing the right gas.

The Need for Precise Temperature Control

High-end atmosphere furnaces offer exceptional temperature stability, with variations as low as ±1°C. This uniformity is not a luxury; it is critical for ensuring that the entire part or batch receives the same thermal treatment, leading to consistent and predictable material properties.

Gas Purity and Flow

The effectiveness of the controlled atmosphere relies on the purity of the source gas and the furnace's ability to maintain a slight positive pressure. This prevents any ambient air from leaking in and contaminating the process, which could ruin the desired outcome.

Making the Right Choice for Your Goal

To select the correct process, you must first define your desired material outcome.

- If your primary focus is improving bulk properties without surface changes: Processes like bright annealing or neutral hardening in an inert or balanced atmosphere are the correct approach.

- If your primary focus is increasing surface hardness and wear resistance: Reactive processes like nitriding or carbonitriding, which use a specifically chosen gas mixture, are necessary.

- If your primary focus is creating solid parts from powders: Sintering in a controlled, often inert, atmosphere is the required method to prevent oxidation and ensure proper particle bonding.

Mastering material science begins with understanding the powerful interplay between temperature and chemical atmosphere.

Summary Table:

| Process Type | Key Applications | Primary Atmosphere Used |

|---|---|---|

| Heat Treatment | Bright Annealing, Neutral Hardening | Inert (e.g., Nitrogen, Argon) |

| Material Synthesis | Sintering, Powder Roasting | Inert or Controlled |

| Surface Modification | Nitriding, Carbonitriding | Reactive (e.g., Nitrogen, Carbon-rich gases) |

Ready to elevate your material processes with precision? KINTEK specializes in advanced high-temperature furnace solutions, including Atmosphere Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum Furnaces, and CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring optimal performance for diverse laboratories. Contact us today to discuss how our expertise can transform your high-temperature applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance