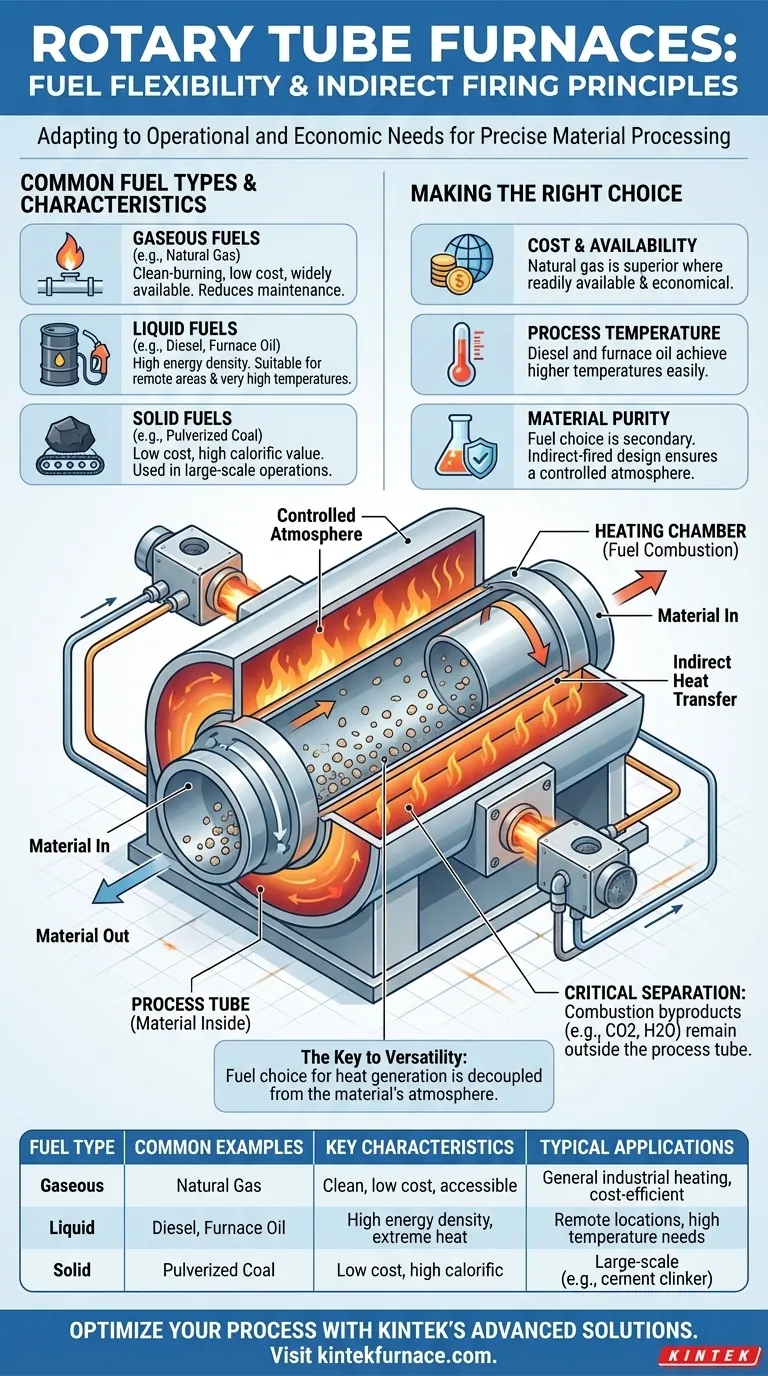

In principle, a rotary tube furnace can burn a wide variety of fuels. This flexibility is one of its core design strengths, allowing it to be adapted to different operational and economic needs. These furnaces are designed to use pulverized solid fuels, various liquid fuels, or gaseous fuels to generate the necessary heat for processing materials.

The critical insight is that rotary tube furnaces are almost always indirectly fired. This means the fuel choice is an operational decision about generating heat, completely separate from the highly controlled atmosphere required for the material inside the tube. This decoupling is the key to their versatility.

The Principle of Indirect Firing

The furnace's design is the reason for its fuel flexibility. The fuel does not interact with the material being processed.

How It Works

A rotary tube furnace consists of a rotating cylindrical tube that passes through a stationary heating chamber. Fuel is burned within this outer chamber, and the resulting heat is transferred through the wall of the tube to the material tumbling inside.

The Critical Separation

This indirect-fired design creates a crucial separation. The byproducts of combustion (like CO2 and water vapor from burning natural gas) remain outside the process tube. This ensures the atmosphere inside the tube, which is in direct contact with the material, can be precisely controlled without contamination.

Common Fuel Types and Their Applications

The selection of a fuel is typically based on a balance of cost, availability, and the required process temperature.

Gaseous Fuels (e.g., Natural Gas)

Natural gas is often the preferred fuel due to its wide availability, relatively low cost, and clean-burning properties. This cleanliness can lead to lower maintenance requirements for the furnace's combustion chamber and burners.

Liquid Fuels (e.g., Diesel, Furnace Oil)

Diesel offers higher energy density than natural gas and is a common choice where gas infrastructure is unavailable. For applications requiring extremely high temperatures, heavier fuels like furnace oil are often used due to their high calorific value.

Solid Fuels (e.g., Pulverized Coal)

While technically possible, using pulverized solid fuels like coal is more common in very large-scale industrial operations, such as cement clinker production. This choice is almost always driven by the low cost of the fuel source.

Understanding the Trade-offs

Choosing the right fuel is not just about what the furnace can burn, but about the practical implications of that choice.

Cost and Availability

This is the most significant factor. The decision often comes down to the regional cost and logistical availability of natural gas versus liquid fuels.

Process Temperature

Higher-energy fuels like diesel and furnace oil can achieve higher temperatures more easily than natural gas. Your target temperature is a primary constraint that may dictate your fuel choice.

Environmental Regulations

Natural gas is a cleaner-burning fuel that produces fewer emissions compared to oil or coal. Increasingly strict environmental regulations can make natural gas the only viable option in certain jurisdictions.

Furnace Design and Maintenance

A furnace must be equipped with the correct type of burner and fuel handling system for a specific fuel. Switching between fuel types, especially from gas to liquid, is not a simple adjustment and requires different hardware and potentially more frequent maintenance.

Making the Right Fuel Choice for Your Process

Your decision should be guided by your primary operational goal.

- If your primary focus is cost-efficiency and clean operation: Natural gas is the superior choice where it is readily and economically available.

- If your primary focus is reaching extreme temperatures or you operate in a location without gas: Diesel and furnace oil are effective, high-energy-density alternatives.

- If your primary focus is material purity (e.g., preventing oxidation): The fuel choice is secondary; focus on ensuring the furnace's indirect-fired design can maintain the required inert or reactive atmosphere inside the tube.

By understanding the indirect-fired principle, you can select the most economical fuel for heating without ever compromising the precise atmospheric conditions your material requires.

Summary Table:

| Fuel Type | Common Examples | Key Characteristics | Typical Applications |

|---|---|---|---|

| Gaseous | Natural Gas | Clean-burning, low cost, widely available | General industrial heating, cost-efficient operations |

| Liquid | Diesel, Furnace Oil | High energy density, suitable for high temperatures | Areas without gas infrastructure, extreme heat needs |

| Solid | Pulverized Coal | Low cost, high calorific value | Large-scale industrial processes like cement production |

Optimize your laboratory's heating processes with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our flexible fuel options and reliable designs can enhance your efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing