In short, a rotary tube furnace can operate under several precisely controlled atmospheres. These include ambient air, inert gases like nitrogen (N₂) and argon (Ar), and reactive gases such as hydrogen (H₂) or steam. The selection is a critical process decision, not an afterthought.

The atmosphere inside a rotary tube furnace is not just a background condition—it is an active variable that directly influences the chemical and physical properties of your final material. Selecting the right atmosphere is as critical as setting the correct temperature and rotation speed.

The Role of Atmosphere in Material Processing

The choice of atmosphere fundamentally depends on your goal: to protect your material from change, or to intentionally cause a chemical change.

The Baseline: Processing in Air

Processing in ambient air is the simplest and most cost-effective option. Air consists primarily of nitrogen and about 21% oxygen.

This is suitable only for materials that are not sensitive to oxidation at high temperatures, such as in the calcination of certain ceramics or minerals where reacting with oxygen is either desired or inconsequential.

Preventing Unwanted Reactions: Inert Atmospheres

The most common reason to control the atmosphere is to prevent oxidation. Inert gases displace oxygen, creating a neutral environment.

Nitrogen (N₂) and Argon (Ar) are the primary choices. They are used for processes like annealing, sintering, or pyrolysis where you need to heat a material without it reacting with its surroundings. This protects the material's purity and surface integrity.

Driving Chemical Change: Reactive Atmospheres

In other cases, the goal is to force a specific chemical reaction. A reactive gas is introduced to act as a chemical agent.

Hydrogen (H₂) is a powerful reducing agent. It is used to strip oxygen atoms from materials, such as when converting metal oxides back into their base metals.

Steam (H₂O) is another common reactive gas. It is often used in processes like biomass gasification or reforming, where it reacts with carbon-based materials to produce synthesis gas (syngas).

How Furnace Design Enables Atmosphere Control

The ability to maintain these specific atmospheres is a core design feature of a rotary tube furnace, not an improvisation.

The Sealed Rotating Tube

The furnace is built around a process tube that can be sealed at both ends. This containment is what allows a specific gas to be introduced, purged of air, and maintained at a positive pressure to prevent leaks.

Uniform Exposure Through Rotation

The continuous rotation of the tube ensures that the entire batch of material is constantly tumbling and mixing. This guarantees every particle is uniformly exposed to the controlled atmosphere and the heat, preventing inconsistencies in the final product.

Integrated Gas Handling Systems

Modern systems include dedicated inert gas packages or gas handling manifolds. These features allow for precise control over the flow rate, pressure, and composition of the gas being fed into the furnace, turning it into a highly controlled chemical reactor.

Understanding the Trade-offs

Choosing an atmosphere involves balancing process requirements with practical limitations like cost and safety.

Cost vs. Purity

Processing in air is free. Using nitrogen is a relatively low-cost option for an inert atmosphere. High-purity argon is significantly more expensive and is typically reserved for highly sensitive materials that might react even with nitrogen at high temperatures.

Safety with Reactive Gases

Using reactive gases like hydrogen introduces significant safety challenges. Hydrogen is highly flammable and requires specialized handling, leak detection systems, and facility ventilation to prevent the risk of explosion.

Material Compatibility

The chosen atmosphere must be compatible not only with the material being processed but also with the furnace components. Certain gases can become corrosive at high temperatures and may degrade the process tube, seals, or other internal parts over time.

Selecting the Right Atmosphere for Your Goal

Your process objective is the single most important factor in determining the correct atmosphere.

- If your primary focus is preventing oxidation (e.g., annealing metals): An inert atmosphere of nitrogen or argon is your standard choice to protect the material's surface integrity.

- If your primary focus is driving a chemical reduction (e.g., converting metal oxides): A reactive atmosphere containing hydrogen (H₂) is necessary to remove oxygen from your material.

- If your primary focus is a specific thermal treatment like gasification (e.g., for carbon materials): A reactive steam (H₂O) atmosphere is often required to achieve the desired chemical conversion.

- If your primary focus is simple calcination without sensitive reactions: Processing in ambient air may be sufficient and is the most cost-effective option.

Ultimately, your choice of atmosphere transforms the furnace from a simple oven into a precise chemical reactor.

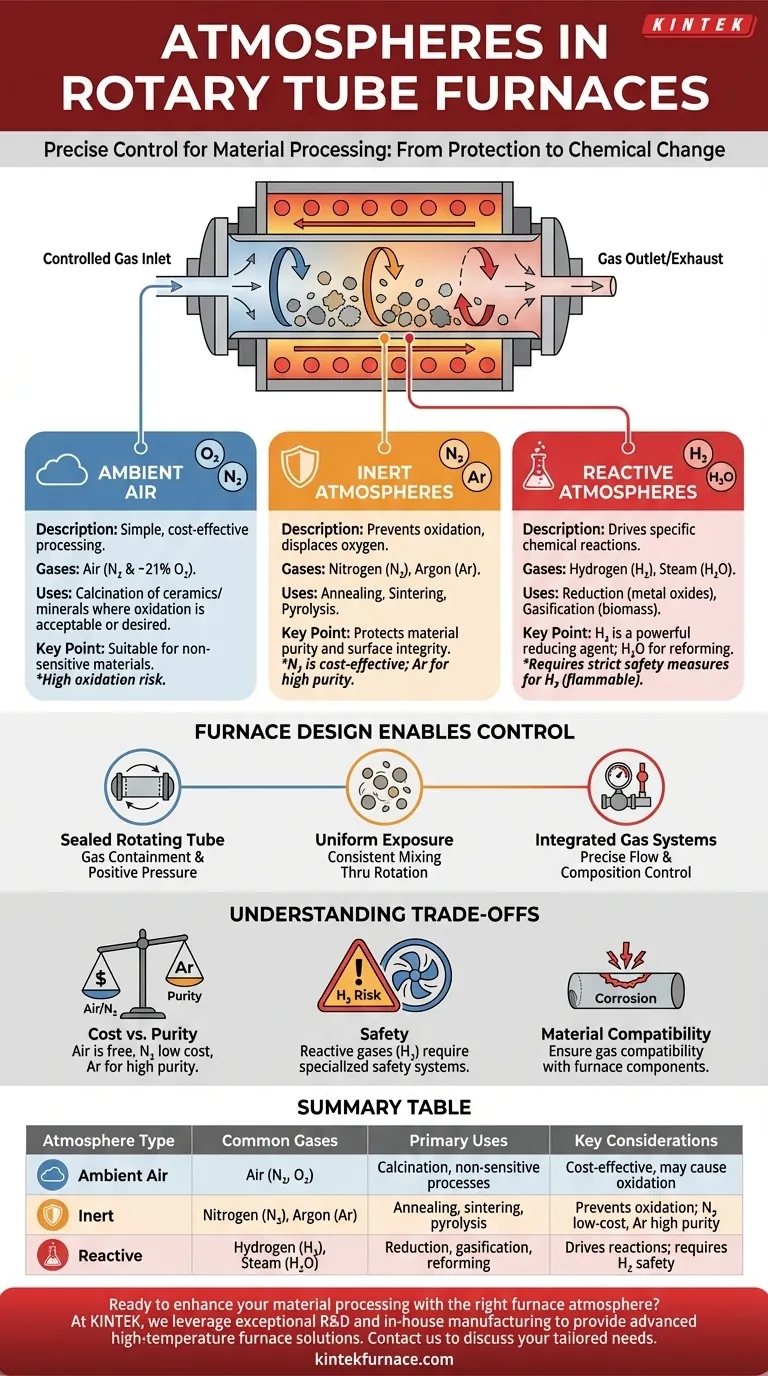

Summary Table:

| Atmosphere Type | Common Gases | Primary Uses | Key Considerations |

|---|---|---|---|

| Ambient Air | Air (N₂, O₂) | Calcination, non-sensitive processes | Cost-effective, but may cause oxidation |

| Inert | Nitrogen (N₂), Argon (Ar) | Annealing, sintering, pyrolysis | Prevents oxidation; nitrogen is low-cost, argon for high purity |

| Reactive | Hydrogen (H₂), Steam (H₂O) | Reduction, gasification, reforming | Drives chemical reactions; requires safety measures for H₂ |

Ready to enhance your material processing with the right furnace atmosphere? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your lab's efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control