In short, a muffle furnace is used for high-temperature analytical tests that require a controlled, contaminant-free environment. Its primary applications are for gravimetric analysis, such as determining the ash or volatile matter content of a sample, preparing samples for subsequent elemental analysis, and testing the thermal properties of materials.

The fundamental value of a muffle furnace is not just its ability to get hot, but its ability to do so within an isolated chamber. This separation from the heating elements prevents sample contamination, ensuring the purity and precision required for accurate scientific analysis.

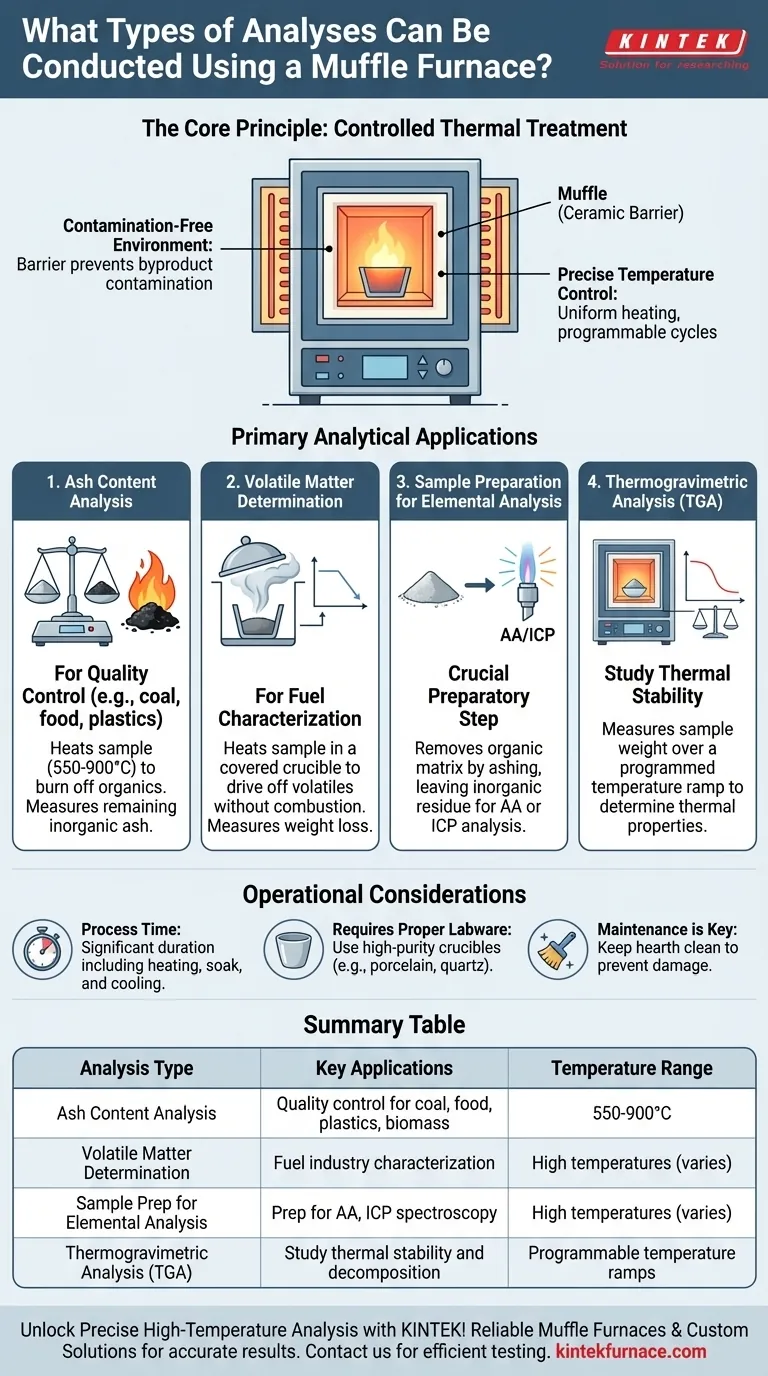

The Core Principle: Controlled Thermal Treatment

A muffle furnace is essentially a high-temperature oven with a critical design feature: the heating elements are external to the main chamber, separated by a "muffle" made of heat-resistant ceramic. This design is the key to its analytical utility.

Contamination-Free Environment

The muffle acts as a barrier, preventing combustion byproducts from the heating elements from contaminating the sample. This is essential for any analysis where the final composition or weight of the sample is the measurement of interest.

Precise Temperature Control

These furnaces are designed for excellent temperature uniformity and precise control, often with programmable cycles. This ensures that the entire sample is heated evenly and that analytical procedures can be repeated with high fidelity, which is critical for quality control and research.

Primary Analytical Applications

The controlled environment of a muffle furnace makes it the ideal instrument for several key types of analysis. These tests generally involve heating a sample to a specific temperature to induce a physical or chemical change, which is then measured.

Ash Content Analysis

This is the most common application. A sample of known weight is placed in a crucible and heated in the furnace at a high temperature (e.g., 550-900°C) until all organic matter has burned away.

The remaining inorganic, non-combustible residue is the ash. By weighing this residue, you can accurately calculate the ash content of the original material. This is a standard quality metric for materials like coal, food products, plastics, and biomass.

Volatile Matter Determination

This analysis measures the amount of volatile compounds that are driven off when a sample is heated under specific conditions. A sample is heated in a covered crucible to a high temperature, which drives off volatiles without allowing combustion.

The weight loss of the sample corresponds to its volatile matter content. This is a critical analysis in the fuel industry, particularly for characterizing coal.

Sample Preparation for Elemental Analysis

A muffle furnace does not perform elemental analysis itself, but it is a crucial preparatory step. By ashing a sample, you remove the complex organic matrix, leaving a concentrated inorganic residue.

This residue can then be dissolved and analyzed using more advanced techniques like Atomic Absorption (AA) spectroscopy or Inductively Coupled Plasma (ICP) to determine its precise elemental composition.

Thermogravimetric Analysis (TGA)

While dedicated TGA instruments exist, a muffle furnace can be used for similar, less automated studies. By subjecting a sample to a programmed temperature ramp and measuring its weight at various intervals, you can study its thermal stability and decomposition profile.

Understanding the Trade-offs and Operational Demands

While powerful, a muffle furnace is not a simple "plug-and-play" device. Achieving accurate results requires understanding its operational characteristics.

Process Time is Significant

While furnaces may heat quickly (e.g., reaching 1000°C in an hour), the entire analytical process includes controlled heating, a long "soak" time at the target temperature, and a slow, controlled cooling period to prevent thermal shock to the chamber and the sample crucibles. A complete cycle can take several hours.

Requires Proper Labware and Handling

Samples must be placed in crucibles made of materials that can withstand the target temperatures without degrading, such as high-purity porcelain or quartz. Care must be taken to avoid splattering, which can damage the furnace's internal chamber.

Maintenance is Key to Longevity

The furnace hearth must be kept clean of any spills, slag, or metal oxides. Prompt cleanup prevents damage to the ceramic muffle and ensures uniform heat distribution for future analyses.

Making the Right Choice for Your Goal

The specific analysis you perform will depend entirely on your objective.

- If your primary focus is quality control for foods, fuels, or polymers: You will primarily use the furnace for determining ash content and volatile matter, as these are standard industry metrics.

- If your primary focus is environmental science or geology: You will use the furnace to prepare soil, water, or rock samples by ashing them before conducting detailed elemental analysis.

- If your primary focus is materials science or R&D: You will use it to test the thermal properties of new materials, perform heat-treatment processes like annealing, or study sintering behavior.

Ultimately, a muffle furnace is an indispensable tool for any analysis that hinges on precise, high-temperature treatment in a clean environment.

Summary Table:

| Analysis Type | Key Applications | Temperature Range |

|---|---|---|

| Ash Content Analysis | Quality control for coal, food, plastics, biomass | 550-900°C |

| Volatile Matter Determination | Fuel industry characterization | High temperatures (varies) |

| Sample Preparation for Elemental Analysis | Prep for AA, ICP spectroscopy | High temperatures (varies) |

| Thermogravimetric Analysis (TGA) | Study thermal stability and decomposition | Programmable temperature ramps |

Unlock precise high-temperature analysis with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for accurate ash content, volatile matter, and thermal testing. Contact us today to enhance your lab's efficiency and achieve contaminant-free results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?