For annealing silicon-based materials, a muffle furnace was selected. This choice was driven by two non-negotiable process requirements: maintaining a precise temperature around 1000°C and creating an environment that actively prevents material oxidation.

The selection of a muffle furnace is fundamentally about achieving atmospheric control. Its design isolates the material, allowing for the creation of an inert environment essential for high-temperature processing of sensitive materials like silicon.

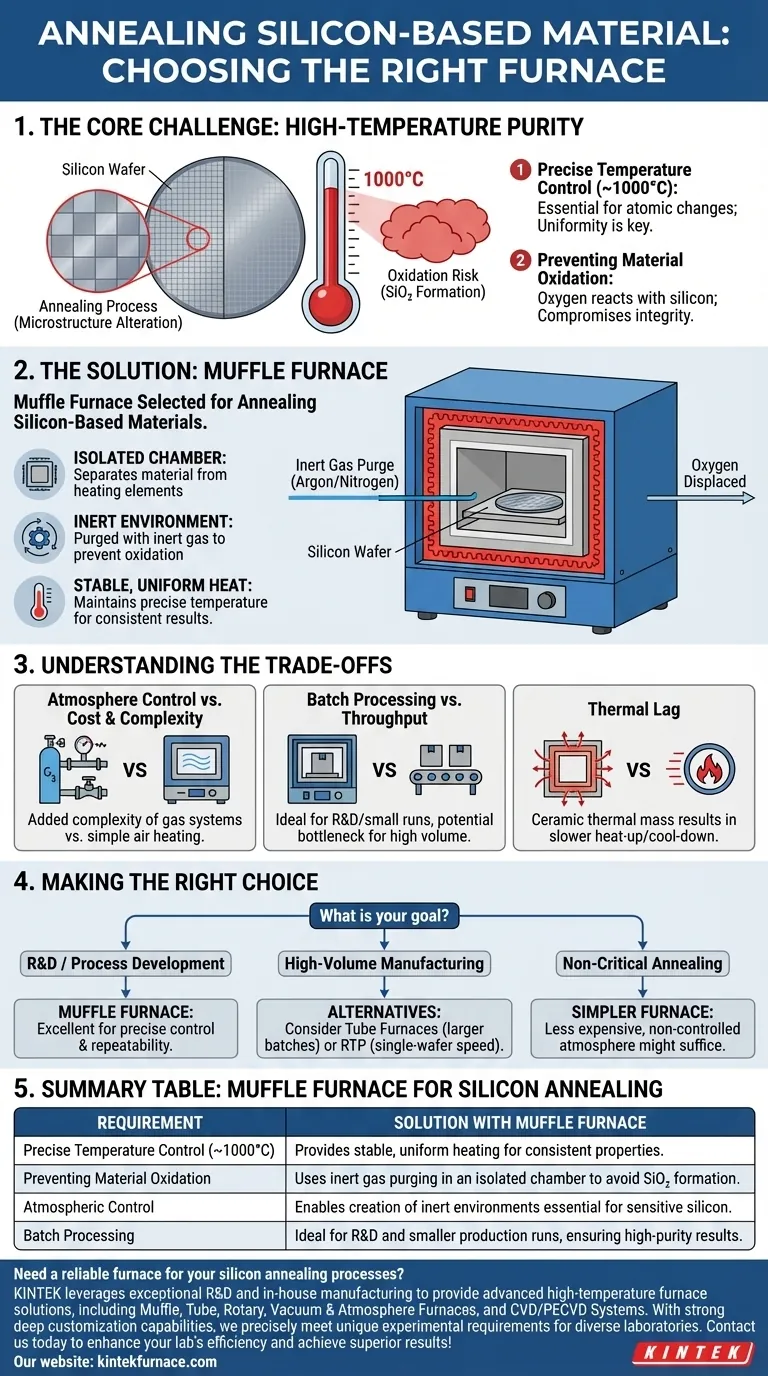

The Core Challenge: High-Temperature Purity

Annealing is a heat treatment process used to alter a material's microstructure to achieve desired properties. For silicon, this often involves repairing crystal lattice damage from ion implantation or activating dopants.

This process requires high heat, but that same heat introduces a significant risk: oxidation.

Requirement 1: Precise Temperature Control (~1000°C)

Annealing is a thermally-activated process, meaning the results are highly dependent on temperature. The 1000°C target is a critical threshold for enabling the necessary atomic-level changes within the silicon crystal.

Inconsistent temperature leads to non-uniform results. A furnace must provide stable, uniform heat across the entire silicon wafer or component to ensure consistent material properties.

Requirement 2: Preventing Material Oxidation

At elevated temperatures, silicon reacts very readily with any available oxygen to form a layer of silicon dioxide (SiO₂). While sometimes intentional (for creating insulating layers), uncontrolled oxidation during annealing is detrimental.

Unwanted oxidation can alter the material's electrical properties, change critical surface dimensions, and interfere with subsequent processing steps. It fundamentally compromises the integrity of the device or material being fabricated.

How a Muffle Furnace Solves the Problem

A muffle furnace is uniquely suited to meet these dual requirements. Its key feature is an inner chamber, or "muffle," typically made of a ceramic material that is separate from the heating elements.

This design creates an isolated volume. The workspace containing the silicon can be sealed and purged with an inert gas, such as argon or nitrogen. This purge displaces all the oxygen, creating the necessary inert atmosphere to prevent oxidation at 1000°C.

Understanding the Trade-offs

While effective, choosing a muffle furnace involves specific considerations. It is not a universal solution for all heat treatment needs.

Atmosphere Control vs. Cost and Complexity

The primary benefit of a muffle furnace is its ability to control the atmosphere. However, this requires gas lines, flow controllers, and proper sealing, adding complexity and cost compared to a simple air furnace.

Batch Processing vs. Throughput

Muffle furnaces are inherently batch-processing tools. You load the material, seal the chamber, run the process, cool down, and unload. This is ideal for research or smaller production runs but can be a bottleneck for high-volume manufacturing.

Thermal Lag

The ceramic muffle that enables atmospheric control also has thermal mass. This means the furnace may have slower heat-up and cool-down rates compared to other systems like Rapid Thermal Processing (RTP) furnaces, which can impact cycle time.

Making the Right Choice for Your Goal

Selecting the correct heating system depends entirely on your end goal and operational constraints.

- If your primary focus is R&D or process development: A muffle furnace is an excellent choice, offering the precise atmospheric and thermal control needed for repeatable, high-purity results.

- If your primary focus is high-volume manufacturing: You must evaluate the throughput limitations and consider alternatives like tube furnaces for larger batches or RTP for single-wafer, high-speed processing.

- If your primary focus is non-critical annealing where a thin oxide layer is tolerable: A simpler, less expensive furnace without full atmospheric control might be a sufficient and more economical solution.

Ultimately, success in annealing silicon hinges on creating a thermally stable and chemically inert environment, a task for which the muffle furnace is exceptionally well-suited.

Summary Table:

| Requirement | Solution with Muffle Furnace |

|---|---|

| Precise Temperature Control (~1000°C) | Provides stable, uniform heating for consistent material properties |

| Preventing Material Oxidation | Uses inert gas purging in an isolated chamber to avoid silicon dioxide formation |

| Atmospheric Control | Enables creation of inert environments essential for sensitive silicon processing |

| Batch Processing | Ideal for R&D and smaller production runs, ensuring high-purity results |

Need a reliable furnace for your silicon annealing processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet unique experimental requirements for diverse laboratories. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing