At a glance, muffle furnaces operate within a vast temperature spectrum, typically ranging from ambient temperatures up to 1800°C (3272°F). Standard laboratory models often operate below 1200°C, while industrial and specialized research furnaces, equipped with advanced heating elements, can reach 1800°C or, in rare cases, even as high as 3000°C.

The specific temperature range of a muffle furnace is not an arbitrary feature. It is a direct consequence of the material used for its internal heating elements, which dictates the furnace's maximum safe operating temperature and, consequently, its cost and application.

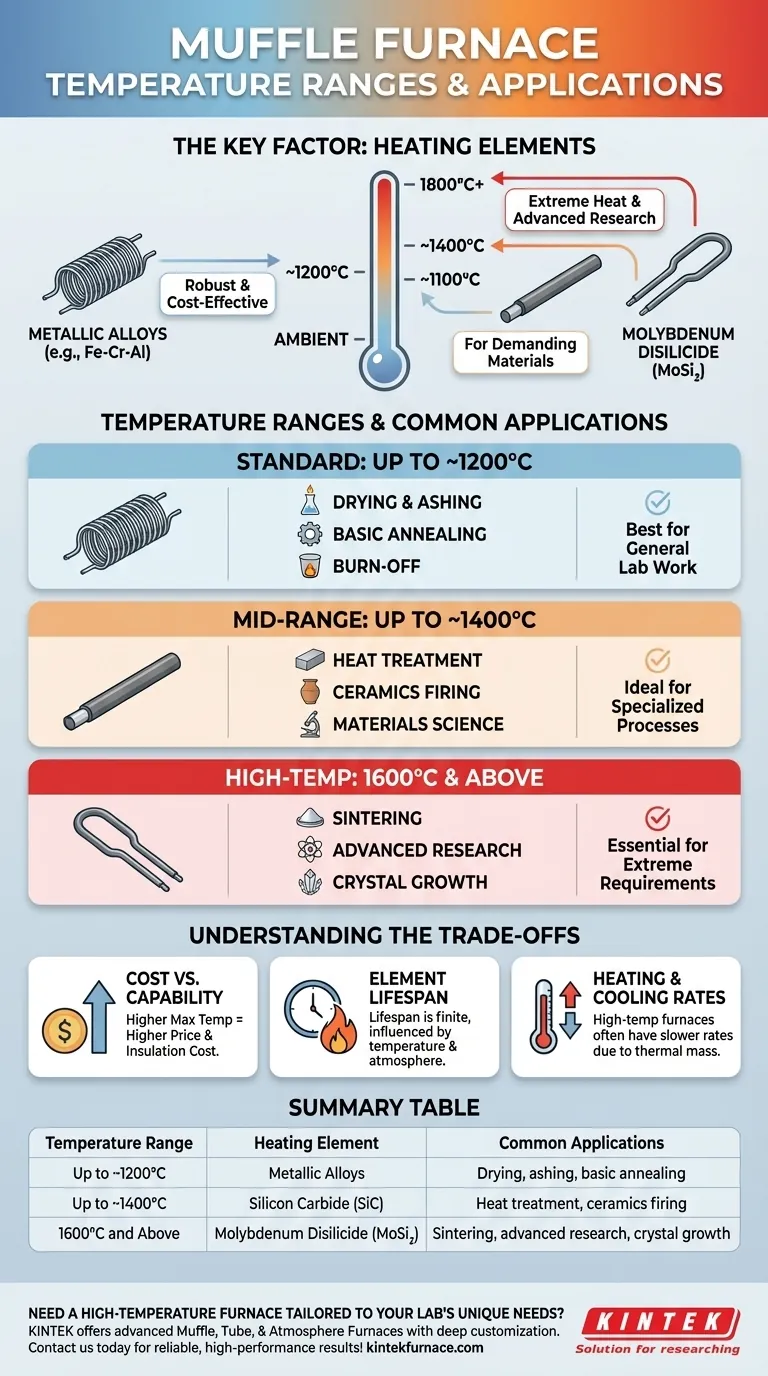

Why Temperature Ranges Vary: The Role of the Heating Element

The single most important factor determining a muffle furnace's temperature capability is the type of electric heating element it employs. Each material has a distinct physical limit beyond which it will degrade or fail.

Standard Furnaces (Up to ~1200°C)

Most general-purpose and many laboratory muffle furnaces operate in this range. They typically use robust metallic wire heating elements, often made from iron-chromium-aluminum alloys.

These are cost-effective and reliable for a wide array of common thermal processes, making them the workhorses of many labs.

Mid-Range Furnaces (Up to ~1400°C)

To achieve temperatures beyond the limits of metallic wires, furnaces must use more advanced materials. The next tier commonly uses Silicon Carbide (SiC) heating rods.

These furnaces are designed for more demanding materials science applications, such as the heat treatment of certain alloys and the firing of some ceramics, which require temperatures between 1100°C and 1300°C.

High-Temperature Furnaces (1600°C and Above)

For the most extreme temperature requirements, furnaces rely on Molybdenum Disilicide (MoSi₂) heating elements.

These specialized units are essential for advanced research, sintering high-performance technical ceramics, growing crystals, and processing refractory metals. Furnaces capable of reaching 1800°C almost exclusively use this type of element.

Matching the Furnace to the Application

The required temperature for your process is the primary filter for selecting a furnace. The muffle design ensures that the sample is heated uniformly and isolated from any potential contamination from the heating elements.

Low-to-Mid Temperature Processes

Applications like drying, sample ashing, burn-off, and basic annealing of metals are typically performed well below 1100°C. A standard box furnace is perfectly suited and the most economical choice for these tasks.

High-Temperature Processes

Demanding processes like sintering ceramics, brazing metals, or calcination of materials require much higher heat. Sintering technical ceramics or certain metals often requires temperatures well above 1500°C, mandating a furnace with MoSi₂ elements.

Beyond Temperature: Precision and Control

Modern muffle furnaces offer fully programmable control over heating rates, hold times, and cooling rates. This ensures that the thermal process is not only hot enough but also precisely repeatable, which is critical for consistent results in both research and production.

Understanding the Trade-offs

Choosing a furnace involves balancing performance needs with practical constraints. Simply opting for the highest possible temperature is often an inefficient and costly mistake.

Cost vs. Capability

There is a direct and steep correlation between a furnace's maximum temperature and its price. A high-temperature furnace using MoSi₂ elements can be many times more expensive than a standard 1200°C lab furnace due to the cost of the elements and the advanced insulation required.

Element Lifespan and Atmosphere

Heating elements are consumables with a finite lifespan that is heavily influenced by operating temperature and the furnace atmosphere. Running a furnace consistently at its maximum rated temperature will shorten element life. Certain atmospheres can also chemically attack the elements, requiring careful selection.

Heating and Cooling Rates

High-temperature furnaces contain dense, highly efficient insulation to maintain extreme heat. A consequence of this thermal mass is that they often heat up and, more significantly, cool down more slowly than lower-temperature models.

Making the Right Choice for Your Process

To select the correct muffle furnace, start by defining the maximum temperature your process requires and then consider your budget and long-term needs.

- If your primary focus is general lab work like ashing or drying below 1100°C: A standard box furnace with a metallic heating element is the most cost-effective and reliable choice.

- If your primary focus is materials science or ceramics requiring 1100°C to 1400°C: A furnace equipped with Silicon Carbide (SiC) elements provides the necessary capability for these mid-range applications.

- If your primary focus is advanced research, sintering metals, or high-temp ceramics above 1500°C: You must invest in a high-performance furnace with Molybdenum Disilicide (MoSi₂) elements to safely and reliably reach these temperatures.

By understanding the direct link between heating elements and temperature capability, you can confidently select the precise furnace your work demands.

Summary Table:

| Temperature Range | Heating Element | Common Applications |

|---|---|---|

| Up to ~1200°C | Metallic Alloys | Drying, ashing, basic annealing |

| Up to ~1400°C | Silicon Carbide (SiC) | Heat treatment, ceramics firing |

| 1600°C and Above | Molybdenum Disilicide (MoSi₂) | Sintering, advanced research, crystal growth |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise fit for your experimental requirements—whether for sintering, materials science, or industrial processes. Contact us today to enhance your lab's efficiency and achieve reliable, high-performance results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis