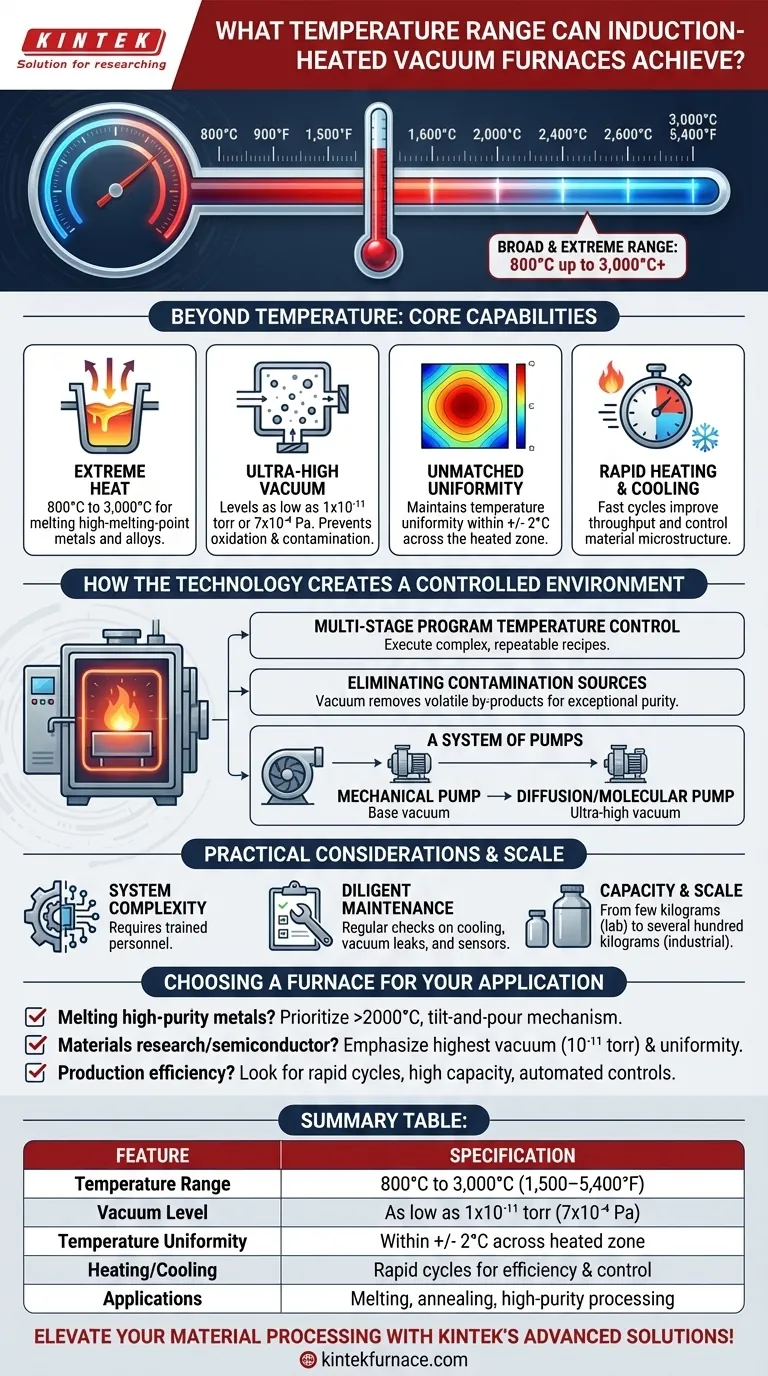

In short, induction-heated vacuum furnaces can operate across a broad and extreme temperature range, typically from 800°C up to 3,000°C (1,500–5,400°F). The specific maximum temperature depends on the furnace's design and intended application, with some models engineered to exceed 2,000°C for melting high-melting-point metals and alloys.

The true value of an induction vacuum furnace isn't just its high-temperature capability, but its ability to combine that heat with an ultra-pure, precisely controlled vacuum environment. This synthesis is what prevents oxidation and contamination, making it essential for processing sensitive, high-performance materials.

Beyond Temperature: The Core Capabilities

Understanding an induction vacuum furnace requires looking past the maximum temperature. The real advantage lies in how it manages the entire thermal process within a pristine environment.

Achieving Extreme Heat

The operational range of these furnaces is vast, starting around 800°C and reaching as high as 3,000°C. This capability makes them suitable for everything from standard heat treatment to the melting and casting of refractory metals and advanced alloys.

The Role of High Vacuum

Heat is only half the equation. These furnaces create an ultra-high vacuum, with levels as low as 1x10⁻¹¹ torr or 7x10⁻⁴ Pa. This near-perfect vacuum is critical for eliminating oxidation and other atmospheric contamination that would otherwise ruin materials at high temperatures.

Unmatched Temperature Uniformity

Reaching a high temperature is one thing; maintaining it evenly is another. Advanced induction furnaces can maintain temperature uniformity within +/- 2°C across the heated zone. This precision is vital for processes like semiconductor annealing, where even slight variations can lead to defects.

Rapid Heating and Cooling

The induction method heats the material or crucible directly, allowing for very fast heating and cooling cycles. This rapid response improves throughput, increases energy efficiency, and provides greater control over the material's final microstructure.

How the Technology Creates a Controlled Environment

The combination of induction heating and vacuum systems delivers a level of process control that is difficult to achieve with other methods.

Advanced Process Control

Modern furnaces are equipped with multi-stage program temperature control systems. Paired with precise vacuum and gas control systems, operators can execute complex, repeatable recipes with high fidelity, ensuring consistent results from batch to batch.

Eliminating Contamination Sources

The vacuum environment actively removes volatile by-products released from the material during heating. This purification process, combined with the lack of atmospheric gases, results in a final product of exceptionally high purity.

A System of Pumps

Achieving an ultra-high vacuum is a two-stage process. A mechanical pump first creates a base vacuum. Then, a diffusion or molecular pump takes over to remove the remaining molecules, reaching the final low-pressure environment required for sensitive work.

Understanding the Practical Considerations

While powerful, these systems have specific operational requirements that are critical for performance and longevity.

System Complexity

An induction vacuum furnace is not a simple oven. It is a complex system involving high-power electronics, water cooling circuits, multiple vacuum pumps, and sophisticated sensors. Proper operation requires trained personnel.

The Need for Diligent Maintenance

Consistent performance depends on regular maintenance. This includes routinely checking water cooling systems, inspecting the chamber for vacuum leaks, keeping the interior clean, and verifying that thermocouples and power supplies are functioning correctly.

Capacity and Scale

These furnaces are not one-size-fits-all. They are available in a wide range of capacities, from small laboratory units handling a few kilograms to large industrial systems capable of processing several hundred kilograms per batch.

Choosing a Furnace for Your Application

The right furnace depends entirely on your end goal. The key is to match the system's specifications to your process-critical requirements.

- If your primary focus is melting high-purity, high-melting-point metals: Prioritize a furnace with a maximum temperature over 2000°C, a robust tilt-and-pour mechanism, and crucibles designed for your specific alloy.

- If your primary focus is materials research or semiconductor processing: Emphasize furnaces with the highest vacuum levels (e.g., 10⁻¹¹ torr) and the tightest temperature uniformity controls to ensure experimental purity and repeatability.

- If your primary focus is production efficiency: Look for models with rapid heating/cooling cycles, high capacity, and automated computer controls to maximize throughput and ensure product consistency.

By understanding these capabilities, you can select a system that provides not just heat, but the precise and pure environment your process demands.

Summary Table:

| Feature | Specification |

|---|---|

| Temperature Range | 800°C to 3,000°C (1,500–5,400°F) |

| Vacuum Level | As low as 1x10⁻¹¹ torr (7x10⁻⁴ Pa) |

| Temperature Uniformity | Within +/- 2°C across heated zone |

| Heating/Cooling | Rapid cycles for efficiency and control |

| Applications | Melting refractory metals, semiconductor annealing, high-purity processing |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with induction-heated vacuum furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for melting high-purity metals, semiconductor processing, and other unique experimental needs—delivering superior purity, temperature control, and efficiency. Contact us today to discuss how we can tailor a furnace to your specific requirements!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency