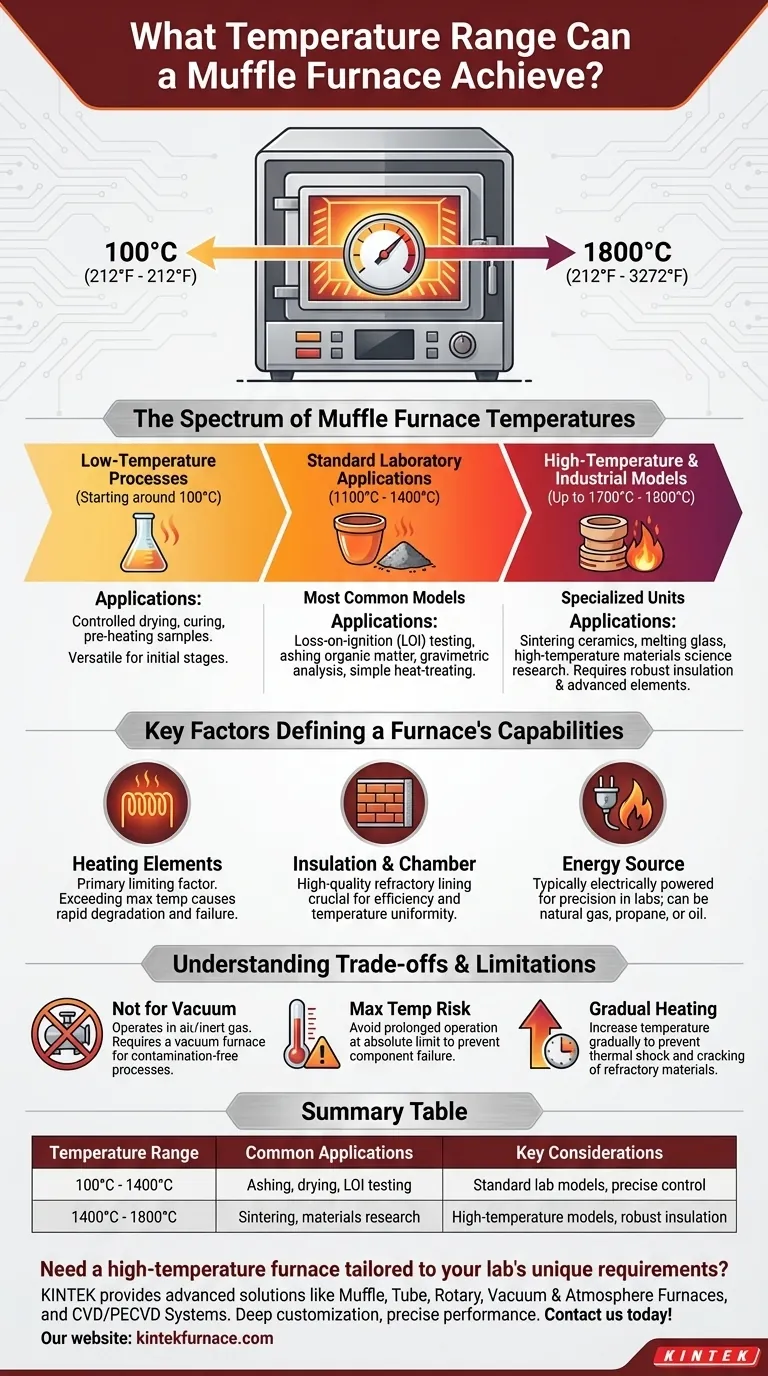

In short, a muffle furnace can typically operate within a wide temperature range, starting from around 100°C (212°F) and reaching up to 1800°C (3272°F). The specific maximum temperature is highly dependent on the furnace's model, construction, and the materials used for its heating elements.

While muffle furnaces are known for achieving high temperatures, the key is understanding that not all models are the same. The maximum temperature rating is the single most important specification, dictating the furnace's suitability for specific thermal processes like ashing, sintering, or heat-treating.

The Spectrum of Muffle Furnace Temperatures

A muffle furnace's primary function is to heat materials in an insulated chamber, separated from the fuel and combustion gases. This capability is applied across a wide temperature spectrum.

Standard Laboratory Applications

Most general-purpose laboratory muffle furnaces are designed to reach maximum temperatures between 1100°C and 1400°C.

This range is more than sufficient for common applications like loss-on-ignition (LOI) testing, ashing organic matter, gravimetric analysis, and simple heat-treating of metals.

High-Temperature and Industrial Models

Specialized and industrial-grade muffle furnaces can achieve much higher temperatures, often reaching 1700°C to 1800°C (3272°F).

These units are built with more robust insulation (like refractory brick) and advanced heating elements. They are required for demanding processes such as sintering ceramics, melting glass, or high-temperature materials science research.

Low-Temperature Processes

The operational range also extends to lower temperatures, starting around 100°C. This makes them versatile enough for controlled drying, curing, or pre-heating samples before a higher-temperature process.

Key Factors Defining a Furnace's Capabilities

The maximum temperature is not an arbitrary number; it is a result of the furnace's specific engineering and materials.

The Critical Role of Heating Elements

The material of the heating elements is the primary limiting factor for a furnace's maximum temperature. Operating the furnace beyond this limit will cause rapid degradation and failure of these components.

Insulation and Chamber Construction

The furnace chamber is lined with high-quality refractory materials. This insulation is crucial for reaching and maintaining high temperatures efficiently and ensuring temperature uniformity within the chamber.

Fuel or Energy Source

Muffle furnaces can be heated by various means, including natural gas, propane, or oil. However, in modern laboratory settings, most are electrically powered for cleaner operation and more precise temperature control.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not the universal solution for all high-temperature work. Understanding its limitations is crucial for safety and success.

Not Suitable for Vacuum Applications

A muffle furnace operates in an air or inert gas atmosphere. It is not designed to hold a vacuum.

For processes requiring a contamination-free environment, such as sintering sensitive materials or certain metallurgical treatments, a vacuum furnace is the correct choice.

The Risk of Operating at Maximum Temperature

You must not exceed the furnace's maximum rated temperature. Furthermore, running the furnace at its absolute limit for prolonged periods should be avoided.

This practice significantly shortens the life of the heating elements and increases the risk of component failure.

The Importance of Gradual Heating

To prevent thermal shock and damage to the furnace chamber or the sample, the temperature should always be increased gradually. Abrupt temperature changes can cause cracking in the refractory materials.

Making the Right Choice for Your Application

Selecting the correct thermal processing equipment requires matching its capabilities to your specific goal.

- If your primary focus is standard lab work like ashing or drying: A model with a maximum temperature of 1200°C to 1400°C offers the best balance of capability and cost.

- If your primary focus is advanced materials or high-temperature sintering: You must invest in a specialized furnace rated for 1700°C, 1800°C, or higher.

- If your primary focus is processing air-sensitive materials: A muffle furnace is inappropriate; your work requires a dedicated vacuum furnace.

Ultimately, choosing the right furnace begins with a clear understanding of the temperature requirements of your specific process.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| 100°C - 1400°C | Ashing, drying, LOI testing | Standard lab models, precise control |

| 1400°C - 1800°C | Sintering, materials research | High-temperature models, robust insulation |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise performance for your thermal processes. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization