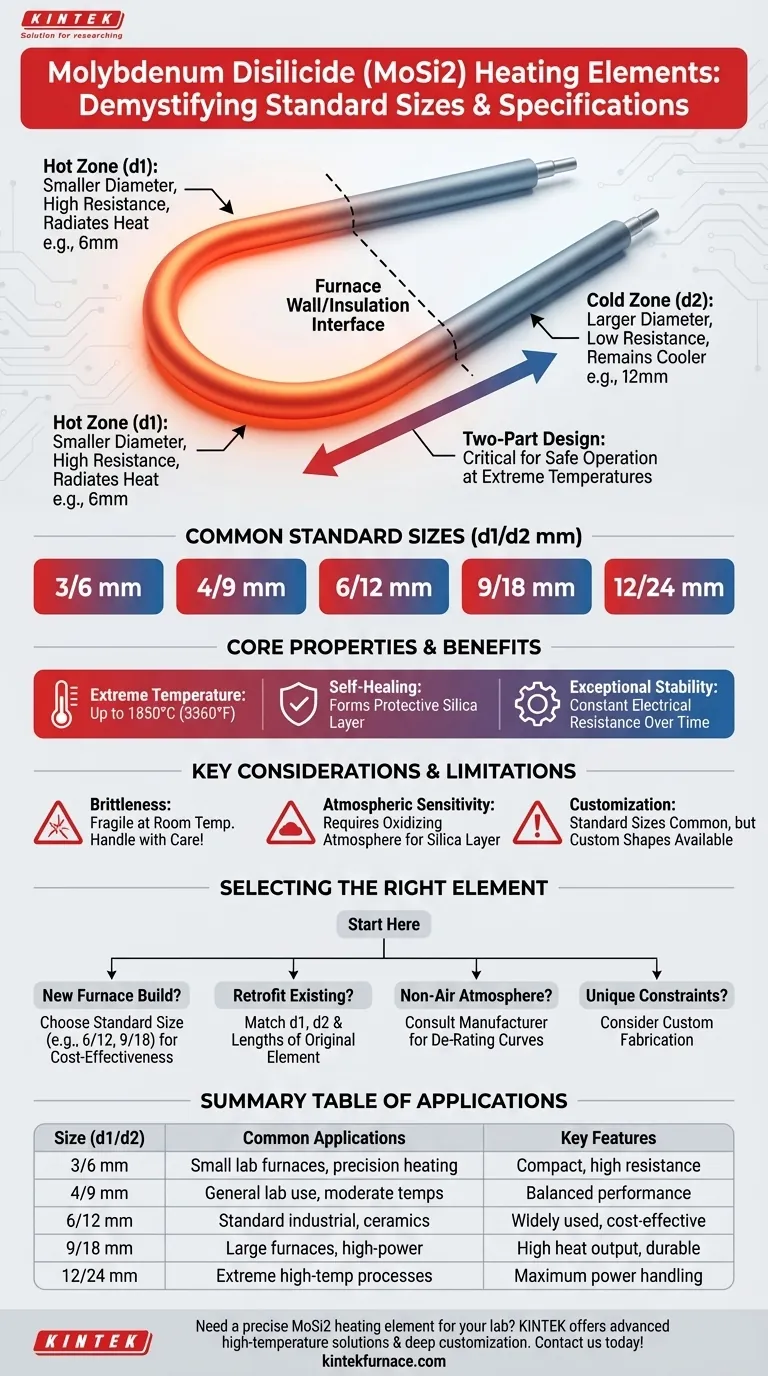

While several standard sizes exist, the most common specifications for Molybdenum Disilicide (MoSi2) heating elements are designated by a two-number system: 3/6, 4/9, 6/12, 9/18, and 12/24 mm. This notation is not arbitrary; it defines the critical diameters of the element's heating and terminal sections, which is essential for proper furnace design and operation.

The key to understanding MoSi2 element sizing is recognizing that the two numbers (e.g., 6/12) represent the diameter of the hot zone and the cold zone, respectively. This two-part design is fundamental to how these elements function safely and efficiently at extreme temperatures.

Demystifying the Size Specification (e.g., 6/12 mm)

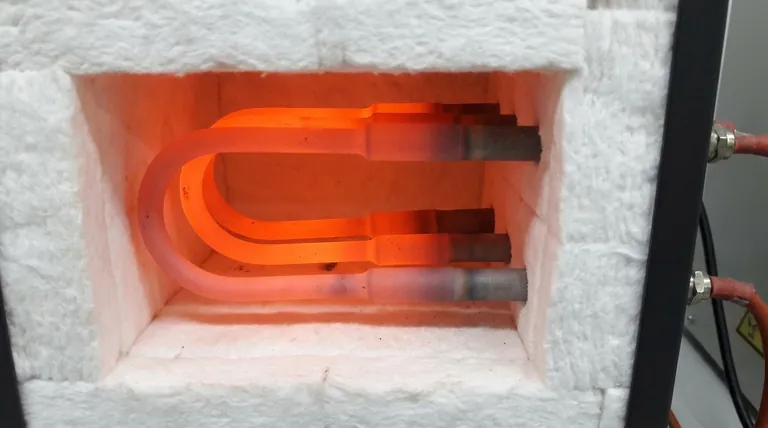

The "U" shape is the most common form for a MoSi2 element. This shape is divided into two distinct sections defined by their diameter.

The Hot Zone (d1)

The first number, such as the 6 in a 6/12 element, refers to the diameter of the heating section, or "hot zone."

This is the smaller-diameter portion of the element that resides inside the furnace chamber. Its smaller cross-section results in higher electrical resistance, causing it to heat up and radiate energy.

The Cold Zone (d2)

The second number, such as the 12 in a 6/12 element, is the diameter of the terminal section, or "cold zone."

This thicker section passes through the furnace wall's insulation. Its larger diameter gives it lower electrical resistance, ensuring it remains significantly cooler than the hot zone. This prevents overheating and damage to the furnace lining and electrical connections.

Why This Two-Part Design is Critical

The design intentionally concentrates heat generation within the furnace chamber while keeping the pass-through terminals cool. This is the core principle that allows MoSi2 elements to operate at extreme temperatures without compromising the structural integrity of the furnace itself.

Core Properties of MoSi2 Elements

Understanding the sizing requires context on why these elements are chosen for demanding applications. Their unique properties dictate their use.

Extreme Temperature Capability

MoSi2 elements are renowned for their ability to operate reliably in air at element temperatures up to 1850°C (3360°F). This makes them ideal for high-temperature processes in ceramics, metallurgy, and glass production.

Self-Healing Oxidation Resistance

When heated in an oxidizing atmosphere (like air), the element forms a thin, protective layer of silica glass (SiO2) on its surface. If this layer is cracked or damaged, it will "heal" itself by re-forming, which prevents the underlying material from degrading.

Exceptional Stability and Longevity

Unlike many other metallic elements, the electrical resistance of MoSi2 does not change with age or use. This stability allows new and old elements to be connected in the same circuit without issue and contributes to a very long operational lifespan.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the trade-offs of MoSi2 is essential for successful implementation and safety.

Brittleness at Room Temperature

Molybdenum disilicide is a cermet (ceramic-metallic composite) and is very brittle and fragile at room temperature. Elements must be handled with extreme care during installation to avoid fracture. They gain ductility as they heat up.

Atmospheric Sensitivity

The protective silica layer can only form in an oxidizing atmosphere. In low-oxygen or reducing atmospheres, the maximum operating temperature must be significantly lowered to prevent accelerated degradation of the element. Always consult manufacturer data for specific de-rating curves.

Customization vs. Standardization

While standard sizes like 6/12 and 9/18 are common and readily available, elements can be custom-fabricated into a wide variety of shapes and sizes. This is often necessary for unique furnace geometries or specialized research applications.

How to Select the Right Element

Your choice depends on your furnace design, operating temperature, and budget.

- If your primary focus is a new, standard furnace build: Begin by designing around common sizes like 6/12 or 9/18 mm, as they are the most cost-effective and widely available.

- If your primary focus is retrofitting an existing furnace: You must match the diameters (d1 and d2) and lengths of the original elements to ensure proper fit and electrical performance.

- If you are operating in a non-air atmosphere: Your first step must be to consult manufacturer specifications to determine the maximum allowable temperature for that specific environment, as this will heavily influence your element choice.

- If you have unique spatial constraints or power requirements: A custom-designed element may be the only viable solution to meet your specific geometric and thermal needs.

Ultimately, selecting the correct MoSi2 element size is a crucial engineering decision that directly impacts furnace performance, efficiency, and safety.

Summary Table:

| Size (Hot Zone/Cold Zone) | Common Applications | Key Features |

|---|---|---|

| 3/6 mm | Small lab furnaces, precision heating | Compact, high resistance in hot zone |

| 4/9 mm | General lab use, moderate temperatures | Balanced performance, good availability |

| 6/12 mm | Standard industrial furnaces, ceramics | Widely used, cost-effective, reliable |

| 9/18 mm | Large furnaces, high-power applications | High heat output, durable for heavy use |

| 12/24 mm | Extreme high-temperature processes | Maximum power handling, for specialized needs |

Need a precise MoSi2 heating element for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to your unique experimental requirements. Contact us today to enhance your furnace performance and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control