At their core, modern ceramic furnaces are distinguished by special features designed for absolute precision and material control. Key capabilities include vacuum firing technology to create flawless, non-porous surfaces, fully automated and programmable firing cycles for perfect repeatability, and the ability to operate under various controlled atmospheres for advanced material processing.

Modern ceramic furnaces have evolved from simple ovens into sophisticated material processing instruments. The most critical features are those that precisely control the firing environment (vacuum and atmosphere) and the firing process (temperature and time), ensuring the final ceramic product meets exact structural and aesthetic specifications.

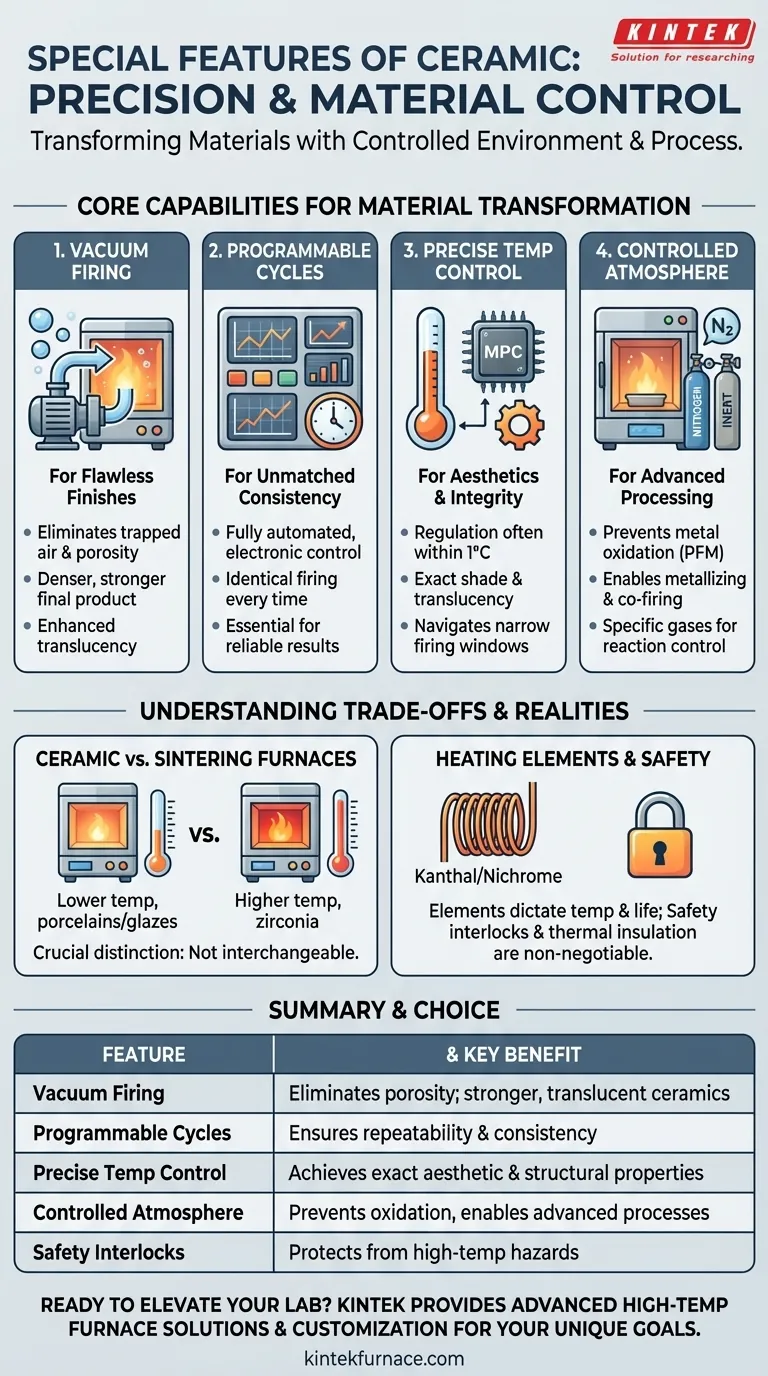

Core Capabilities for Material Transformation

The goal of a ceramic furnace is not just to heat a material, but to transform it. The following features are central to achieving a controlled, predictable transformation.

Vacuum Firing for Flawless Finishes

The most significant feature for high-quality aesthetic work, especially in dentistry, is an integrated vacuum system.

During the firing cycle, the vacuum pump removes air from the firing chamber. This eliminates the risk of trapping air bubbles within the ceramic, which can cause porosity, weakness, and a cloudy appearance. The result is a denser, stronger, and more translucent final product.

Programmable Cycles for Unmatched Consistency

Modern furnaces are electronically controlled and fully programmable. Users can create, store, and run specific firing programs tailored to different types of porcelain or ceramic materials.

This automation ensures that every firing cycle is identical, from the rate of temperature increase to the holding time and cooling phase. This consistency is critical for producing reliable results and is a non-negotiable feature for any professional application.

Precise Temperature Control for Aesthetics and Integrity

Advanced microprocessors and high-quality thermocouples provide exceptionally precise temperature regulation, often within a single degree.

This level of control is essential for developing the exact shade, translucency, and physical properties of the ceramic. Different materials have very narrow firing windows, and any deviation can ruin the final restoration or component.

Controlled Atmosphere for Advanced Processing

Beyond a vacuum, many industrial and advanced dental furnaces can introduce specific gases into the chamber.

Operating in an atmosphere of nitrogen or another inert gas can prevent oxidation of metals in porcelain-fused-to-metal (PFM) restorations. Other processes like metallizing or co-firing ceramics and metals depend entirely on having a controlled, non-reactive atmosphere.

Understanding the Trade-offs and Practical Realities

While features are important, understanding their context is key to making an informed decision.

Ceramic Furnaces vs. Sintering Furnaces

It is crucial to distinguish between these two types of equipment. Ceramic furnaces, using Kanthal or Nichrome elements, typically operate at lower temperatures suitable for firing porcelains and glazes.

Sintering furnaces, in contrast, are designed to reach much higher temperatures required to process high-strength materials like monolithic zirconia. They are used for different stages of the production process and are not interchangeable.

The Importance of Heating Elements

The choice of heating element (like Kanthal or Nichrome) dictates the furnace's maximum temperature and operational lifespan.

While these are standard in conventional ceramic furnaces, their condition and quality directly impact temperature accuracy and uniformity within the chamber.

Safety as a Non-Negotiable Feature

Modern furnaces are built with operator safety as a priority. Key features include high-efficiency thermal insulation, which keeps the external surfaces cool and improves energy efficiency.

Additionally, safety interlocks prevent the door from being opened while the furnace is at a dangerously high temperature, protecting the user from severe burns and the ceramic piece from thermal shock.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the materials you use and the results you need to achieve.

- If your primary focus is aesthetic dental restorations (e.g., PFM, lithium disilicate): Prioritize a furnace with exceptional vacuum technology and precise, easily programmable firing cycles.

- If your primary focus is industrial processing or materials research: You need a versatile furnace with controlled atmosphere capabilities and the ability to handle various processes like annealing or metallizing.

- If your primary focus is a high-volume lab prioritizing efficiency and safety: Full automation, a user-friendly interface, and robust safety interlocks are your most critical features.

Ultimately, understanding these specialized features empowers you to select not just a furnace, but a precise tool engineered for your specific material goals.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Vacuum Firing | Eliminates porosity for stronger, more translucent ceramics |

| Programmable Cycles | Ensures repeatability and consistency in firing processes |

| Precise Temperature Control | Achieves exact aesthetic and structural properties |

| Controlled Atmosphere | Prevents oxidation and enables advanced material processing |

| Safety Interlocks | Protects users and materials from high-temperature hazards |

Ready to elevate your laboratory's capabilities with a ceramic furnace tailored to your needs? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on aesthetic dental restorations, industrial processing, or high-volume efficiency, we can help you achieve superior results. Contact us today to discuss how our furnaces can transform your material processing!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations