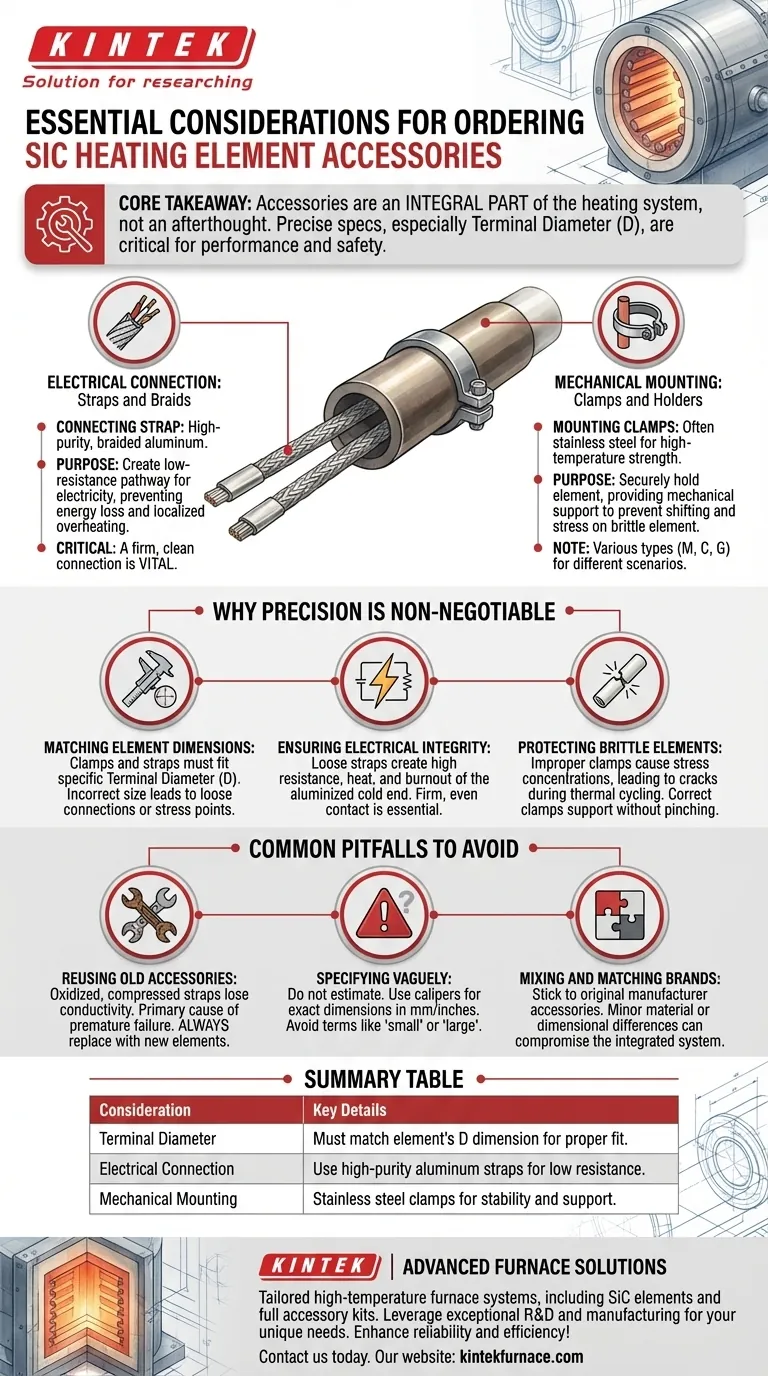

When ordering accessories for silicon carbide (SiC) heating elements, the single most important consideration is providing the precise specifications of the elements they will be paired with. Primarily, this means specifying the element's terminal diameter (D), as accessories like connecting straps and mounting clamps are sized to match this dimension perfectly. These are not generic parts; they are precision components critical for performance and safety.

The core takeaway is that accessories for SiC elements are not an afterthought—they are an integral part of the heating system. Using the correct, manufacturer-recommended straps and clamps is essential for ensuring proper electrical conductivity, providing mechanical stability, and ultimately maximizing the lifespan of the brittle and expensive elements.

The Two Critical Categories of Accessories

To ensure system reliability, it's helpful to think of accessories in two distinct functional groups: those for electrical connection and those for mechanical mounting.

Electrical Connection: Straps and Braids

The primary accessory for electrical connection is the connecting strap or braid. These are typically made of high-purity, braided aluminum for its excellent conductivity.

Their purpose is to create a low-resistance pathway for electricity from the power supply to the element's cold end. A firm, clean connection is vital to prevent energy loss and localized overheating.

Mechanical Mounting: Clamps and Holders

Mounting clamps or fixing fixtures are used to securely hold the SiC element in place as it passes through the furnace wall. These are often made of stainless steel for high-temperature strength and durability.

They provide critical mechanical support, preventing the brittle element from shifting or experiencing stress. Manufacturers often offer specific types (sometimes coded as M, C, or G type) designed for different installation scenarios.

Why Precision is Non-Negotiable

Ordering the wrong accessories can lead to rapid element failure, unplanned downtime, and safety hazards. The need for precision comes down to three key factors.

Matching Element Dimensions

Accessories are not "one size fits all." Clamps and straps are designed to fit the specific terminal diameter (D) of your SiC element. An incorrect size will result in either a loose connection or a stress point on the element.

Ensuring Electrical Integrity

A loose or poorly fitted connecting strap creates high electrical resistance. This generates intense heat at the terminal connection, which can quickly burn out the aluminized cold end of the element and cause it to fail. The clamp and strap must make firm, even contact.

Protecting Brittle Elements

SiC elements are ceramic and are very hard, but also brittle. Improperly sized clamps can create stress concentrations, leading to cracks and fractures, especially during the thermal expansion and contraction of heat cycles. Correctly designed clamps support the element without pinching it.

Common Pitfalls to Avoid

Mistakes in ordering or installation are common but easily preventable. Paying attention to these details is critical for system longevity.

Pitfall: Reusing Old Accessories

Never reuse old connecting straps when replacing elements. Straps oxidize and compress over time, losing their conductivity and springiness. Reusing them is a primary cause of terminal-end burnout and premature element failure.

Pitfall: Specifying Vaguely

Do not order based on estimations. Use calipers to measure your element's terminal diameter if you are unsure. Always provide exact dimensions in millimeters or inches, as specified by the manufacturer, rather than asking for a "small" or "large" clamp.

Pitfall: Mixing and Matching Brands

Heating element manufacturers design their elements, straps, and clamps to function as an integrated system. While components from different suppliers may look similar, minor differences in material or dimensions can compromise the entire setup. Stick with the original manufacturer's accessories whenever possible.

Making the Right Choice for Your System

Use these guidelines to ensure you order the correct components every time, safeguarding the performance and lifespan of your heating system.

- If your primary focus is a new furnace installation: Order the SiC elements and all accessories as a complete, matched kit directly from the element manufacturer.

- If your primary focus is replacing failed elements: Always order a new set of connecting straps and clamps for each new element you install.

- If your primary focus is preventative maintenance: Proactively inspect straps for signs of overheating or oxidation and replace them to prevent unplanned failure.

Treating your heating element accessories as the precision components they are is the key to running a reliable and efficient high-temperature process.

Summary Table:

| Consideration | Key Details |

|---|---|

| Terminal Diameter | Must match element's D dimension for proper fit |

| Electrical Connection | Use high-purity aluminum straps for low resistance |

| Mechanical Mounting | Stainless steel clamps for stability and support |

| Common Pitfalls | Avoid reusing old straps, vague specs, and mixing brands |

Ensure your high-temperature processes run smoothly with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, from SiC heating elements to full accessory kits. Contact us today to enhance reliability and efficiency in your lab!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer