Handling samples in a muffle furnace demands strict adherence to safety protocols. The most critical things to avoid are introducing any form of moisture or volatile substances, subjecting the furnace to sudden temperature changes, and physically damaging the interior components. Failing to do so can lead to violent explosions, catastrophic equipment failure, and severe personal injury.

The core principle of safe furnace operation is managing thermal energy and material reactions. Most serious accidents and damage are not random; they are the direct result of thermal shock or uncontrolled pressure events caused by introducing volatile materials into an extreme-heat environment.

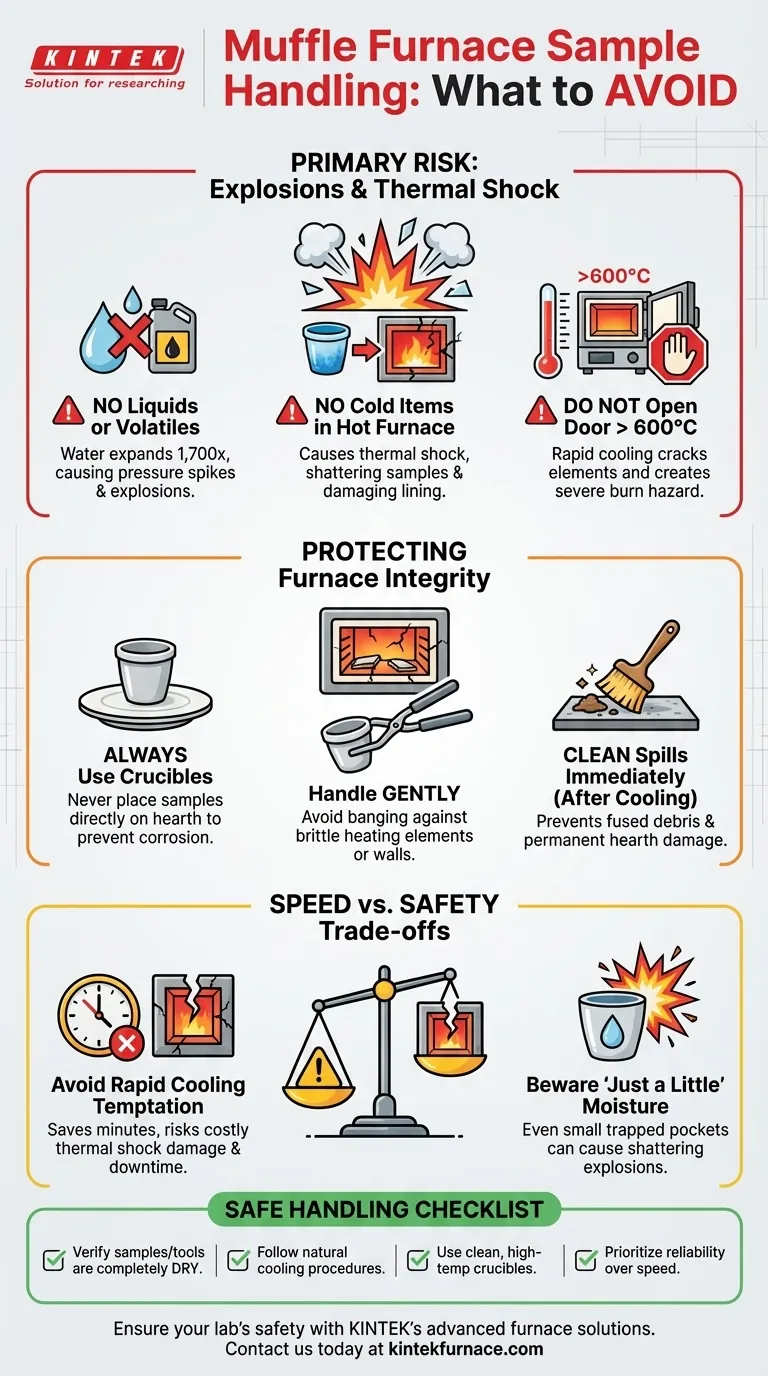

The Primary Risk: Preventing Explosions and Thermal Shock

The most immediate danger when using a muffle furnace comes from rapid, uncontrolled energy release. Understanding the triggers for these events is essential for safe operation.

Avoid All Liquids and Volatiles

Never introduce samples containing water, oils, or other combustible materials into the furnace. This also applies to tools; crucible tongs must be clean and dry.

When heated, a small amount of water instantly flashes into steam, expanding to roughly 1,700 times its original volume. This creates a sudden pressure spike that can shatter a crucible, damage heating elements, or even blow the furnace door open.

Never Introduce Cold Items into a Hot Furnace

Placing a room-temperature sample or crucible into a pre-heated furnace chamber causes thermal shock.

The extreme temperature differential can crack or shatter the sample container and, in severe cases, damage the furnace's refractory lining. Always place samples in a cold furnace and heat them together.

Do Not Open the Door Above 600°C

Opening the furnace door while at high temperatures introduces a rush of cool, dense air. This rapid temperature change can crack the delicate heating elements and the ceramic insulation.

It also creates an immediate and severe burn hazard for the operator. Allow the furnace to cool down naturally below this threshold before retrieving samples.

Protecting the Integrity of the Furnace Chamber

A muffle furnace is a precision instrument whose longevity depends on maintaining the condition of its internal chamber. Physical damage and contamination are the primary threats.

Always Use Appropriate Crucibles

Samples must never be placed directly on the furnace hearth. They should be contained within high-temperature-resistant porcelain or ceramic crucibles.

This prevents the sample from melting, spattering, or reacting with the furnace floor, which can lead to permanent corrosion and damage. An asbestos board or ceramic plate can offer an extra layer of protection.

Handle Crucibles and Samples Gently

The furnace's internal components, including the refractory brick lining and heating elements, are often brittle.

When placing or removing crucibles, use tongs carefully and avoid banging them against the furnace walls or floor. Such impacts can easily chip or crack these critical components, leading to costly repairs and operational downtime.

Clean Spills and Debris Immediately

If a sample spills or a crucible breaks, any resulting slag, metal oxides, or debris must be cleaned out promptly after the furnace has fully cooled.

If left inside, this material can fuse to the furnace hearth during the next heating cycle, causing permanent damage and interfering with uniform heat distribution.

Understanding the Trade-offs: Speed vs. Safety

In any lab or industrial setting, there is pressure to complete processes quickly. However, with a muffle furnace, attempts to save time often introduce unacceptable risks.

The Temptation of Rapid Cooling

The desire to access samples quickly often tempts operators to open the door prematurely to speed up cooling.

This is a false economy. While it may shave minutes off the cooling time, it drastically increases the risk of thermal shock, which can cause damage that results in days or weeks of downtime and expensive repairs.

The Danger of "Just a Little" Moisture

An operator might assume a slightly damp sample is acceptable. This is a dangerous assumption.

Even a small pocket of trapped moisture can generate enough explosive force to shatter the sample container, ruining the experiment and contaminating the entire furnace chamber with debris.

A Checklist for Safe Sample Handling

To ensure safety and reliable results, align your procedure with your primary objective.

- If your primary focus is operator safety and equipment longevity: Never deviate from the manufacturer's cooling procedures and always verify samples and tools are completely dry before use.

- If your primary focus is sample integrity and accurate results: Use clean, high-temperature crucibles and avoid any action that could cause sample spatter or contamination, such as rapid heating or cooling cycles.

- If your primary focus is operational efficiency: Acknowledge that true efficiency comes from process reliability and avoiding downtime, not from cutting corners on safety protocols that risk catastrophic failure.

Proper sample handling is not about blindly following rules; it's about controlling a powerful process with precision and respect.

Summary Table:

| Avoidance Area | Key Risks | Prevention Tips |

|---|---|---|

| Liquids and Volatiles | Explosions from steam expansion | Use dry samples and tools only |

| Sudden Temperature Changes | Thermal shock, element damage | Heat samples from cold; cool naturally |

| Physical Damage | Cracked components, contamination | Handle crucibles gently; clean spills after cooling |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can support your operations!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the difference between electric furnace and muffle furnace? A Guide to Choosing the Right Heating Solution

- What precautions should be taken when using a muffle furnace for the first time or after a long shutdown? Ensure Safe and Long-Lasting Operation

- Why is a programmable temperature ramp rate essential in muffle furnace operations for nanomaterial precursors?

- What role does a muffle furnace play in the preparation of ER-SnmCunOx-t/CC electrocatalysts? Achieve Optimal Purity

- What are the primary uses of muffle furnaces in the pharmaceutical industry? Ensure Drug Purity and Stability

- What critical role does a high-temperature sintering furnace play in the treatment of Zinc Oxide pellets? Expert Insights

- What are the key operational features of modern muffle furnaces? Enhance Precision and Efficiency in Your Lab

- How should materials be selected for use in a Muffle furnace? Optimize Your High-Temperature Processes