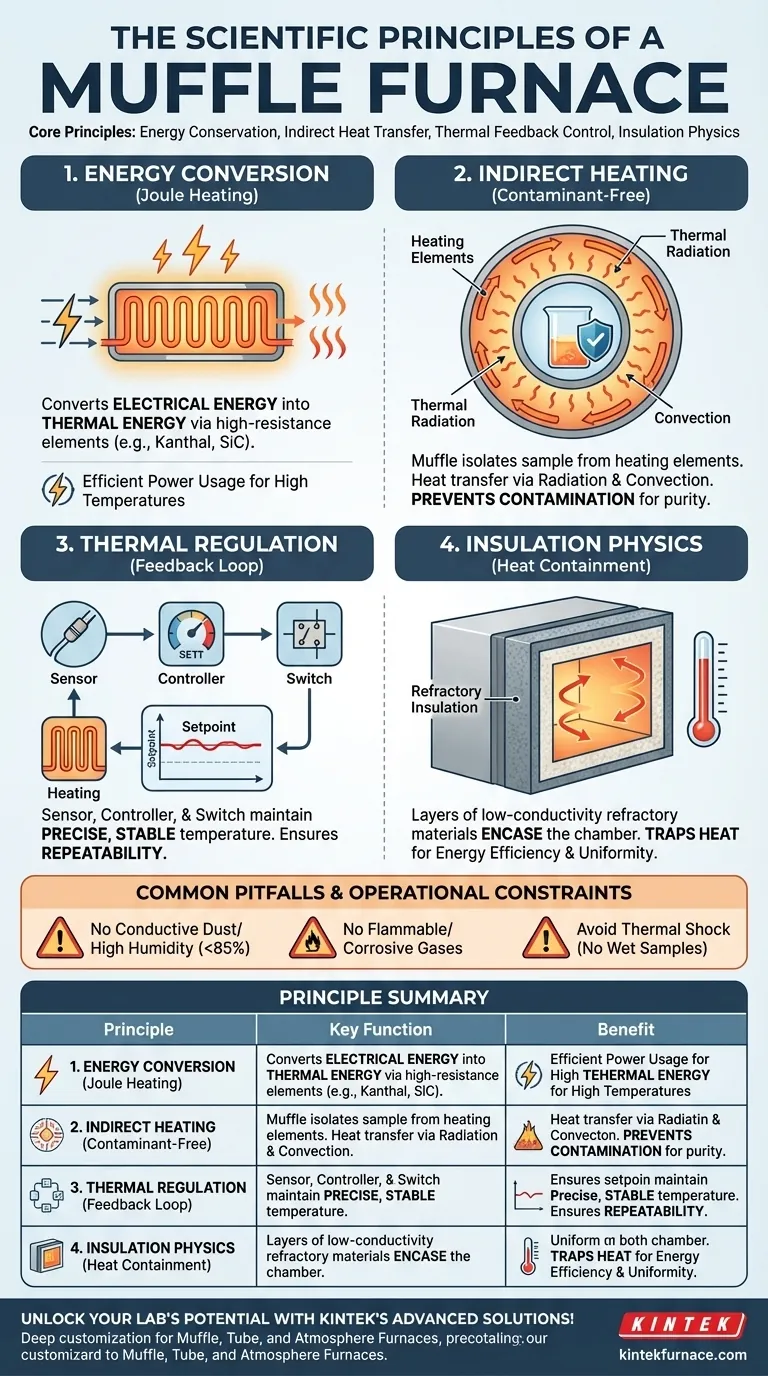

At its core, a muffle furnace operates on four key scientific principles: the conservation of energy, indirect heat transfer, thermal feedback control, and the physics of insulation. These principles work in concert to convert electrical energy into precisely controlled heat within a clean, isolated chamber, enabling a wide range of high-temperature material processing applications.

A muffle furnace is not just a simple oven; it is a system designed to solve a specific problem. It leverages fundamental physics to create a highly uniform, stable, and contaminant-free thermal environment by physically separating the material being heated from the raw heat source itself.

The Foundation: Energy Conversion

The operation of any furnace begins with the First Law of Thermodynamics, which states that energy cannot be created or destroyed, only converted from one form to another.

The Principle of Joule Heating

A muffle furnace converts electrical energy into thermal energy. This is achieved through a principle known as Joule heating.

When an electric current passes through the furnace's heating elements, which are made of a high-resistance material, the resistance causes the electrical energy to dissipate as heat.

The Role of Heating Elements

These elements are typically made from alloys like Kanthal or ceramics like silicon carbide, chosen for their ability to withstand extremely high temperatures while maintaining high electrical resistance.

The Defining Principle: Indirect Heating

The name "muffle" furnace comes from its defining feature: the muffle, an inner chamber that separates the sample from the heating elements. This design is central to its function.

How Heat is Transferred

The heating elements heat the space outside the muffle. This heat is then transferred to the sample inside the chamber primarily through two mechanisms:

- Thermal Radiation: The hot interior walls of the muffle radiate heat evenly onto the sample.

- Convection: The air or inert atmosphere inside the chamber circulates, transferring heat throughout the space.

The Benefit: A Contaminant-Free Environment

This indirect heating method is critical. It prevents any byproducts from the heating elements (such as element degradation or atmospheric reactions at high temperatures) from contaminating the sample being processed. This ensures the chemical purity of the final product.

Achieving Precision: Thermal Regulation

A muffle furnace's value lies in its ability to maintain a precise, stable temperature. This is accomplished through a classic feedback control system.

The Feedback Loop Explained

The system has three main parts: a sensor, a controller, and a switch.

- Sensor (Thermocouple): A thermocouple inside the chamber measures the actual temperature.

- Controller: You set a desired temperature (the setpoint). The controller constantly compares the thermocouple's reading to this setpoint.

- Switch (Relay): If the temperature is too low, the controller signals the relay to send power to the heating elements. If the temperature reaches the setpoint, it cuts the power.

Maintaining Stability

This continuous cycle of measuring and adjusting (often indicated by green and red lights on the control panel) allows the furnace to hold a specific temperature with remarkable stability, which is essential for repeatable scientific experiments and industrial processes.

Maximizing Efficiency: The Physics of Insulation

Generating high temperatures is energy-intensive. To be effective, a muffle furnace must contain that heat.

Containing the Heat

The furnace chamber is encased in layers of high-performance insulation, typically made from refractory ceramic fibers or bricks. These materials have very low thermal conductivity, meaning they are extremely poor at transferring heat.

Ensuring Uniformity

Excellent insulation does more than just save energy. By preventing heat from escaping, it helps create a uniform thermal environment inside the chamber, ensuring the entire sample experiences the same temperature.

Common Pitfalls and Operational Constraints

The scientific principles that make a muffle furnace effective also dictate strict operational limits. Ignoring these can lead to equipment damage, failed processes, and serious safety hazards.

Environmental Requirements

The furnace must operate in an environment with low relative humidity (under 85%) and free of conductive dust. Moisture and conductive particles can create short circuits in the high-power electrical system.

Chemical Safety Hazards

The operating environment must be completely free of flammable, explosive, or corrosive gases. High temperatures can ignite flammable materials, while corrosive gases will rapidly attack and destroy the heating elements and the thermocouple.

Thermal Shock and Material Limits

Never exceed the furnace's maximum rated temperature, as this will permanently damage the heating elements. Likewise, never pour liquids or place wet samples into a hot furnace. The rapid temperature change can cause thermal shock, cracking the ceramic muffle.

Making the Right Choice for Your Goal

Understanding these principles helps you use a muffle furnace effectively and safely.

- If your primary focus is process repeatability: Your success depends on the precision of the thermal regulation system; a stable feedback loop is your key to consistent outcomes.

- If your primary focus is sample purity: Recognize that the indirect heating "muffle" design is your greatest asset, as it isolates your material from potential contaminants.

- If your primary focus is safety and longevity: Adhere strictly to the operational constraints, as they are direct applications of the physical and chemical limits of the furnace's materials.

By understanding these governing principles, you can better control your process and ensure reliable, safe, and accurate results.

Summary Table:

| Principle | Key Function | Benefit |

|---|---|---|

| Energy Conversion | Converts electrical energy to heat via Joule heating | Efficient power usage for high temperatures |

| Indirect Heating | Uses a muffle to separate sample from heating elements | Prevents contamination, ensures sample purity |

| Thermal Regulation | Employs feedback control with thermocouples | Maintains precise, stable temperatures for repeatability |

| Insulation Physics | Uses refractory materials to contain heat | Enhances energy efficiency and temperature uniformity |

Unlock the full potential of your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior performance and safety. Contact us today to discuss how we can enhance your material processing and achieve contaminant-free, repeatable results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation