To safely operate a muffle furnace, you must combine correct environmental setup, mandatory personal protective equipment (PPE), and strict adherence to operational protocols. Key precautions include ensuring proper electrical grounding, wearing heat-resistant gloves and goggles, never exceeding the furnace's maximum temperature, and avoiding the introduction of liquids or explosive materials. Safe operation is a systematic process, covering every stage from initial setup to final shutdown.

A muffle furnace is not inherently dangerous, but it demands respect. True safety is achieved not by following a single rule, but by adopting a comprehensive mindset that prioritizes environmental stability, operator protection, and equipment integrity at all times.

Foundational Safety: The Environment and Setup

Before you ever turn the furnace on, you must ensure its operating environment is secure. This foundational step prevents the most common electrical and fire-related accidents.

Proper Electrical Installation

The furnace must be placed on a stable, non-combustible surface, such as a cement platform. Ensure it is connected to a dedicated circuit with the correct plugs, sockets, and fuses to avoid overloading.

Crucially, proper grounding is non-negotiable. This is your primary defense against electric shock in the event of an electrical fault.

Stable and Clear Workspace

The area surrounding the furnace must be completely free of flammable, explosive, or corrosive substances. High temperatures can easily ignite nearby materials or cause volatile chemicals to react.

Adequate laboratory ventilation is also essential to safely dissipate any fumes or gases that may be released from your samples during the heating process.

Operator Safety: Personal Protection and Handling

With the environment secured, the focus shifts to protecting the operator. Your actions and attire are critical to preventing burns and other injuries.

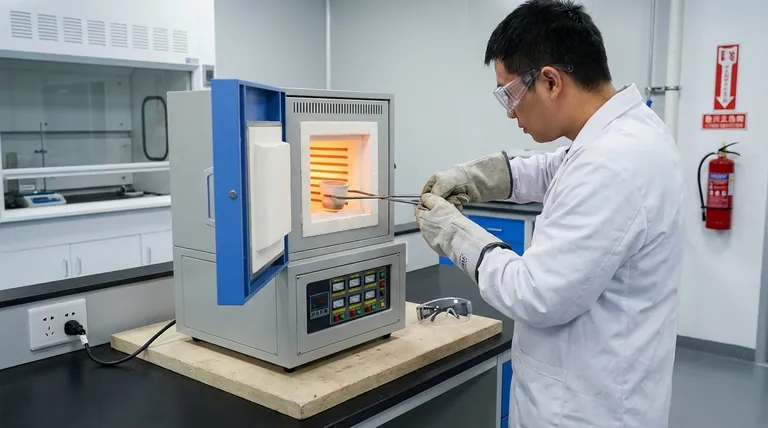

Use Appropriate Personal Protective Equipment (PPE)

Always wear heat-resistant gloves when handling crucibles or items that have been in the furnace. Safety goggles are mandatory to protect your eyes from heat shimmer and potential debris.

Handle Materials and Doors with Care

When placing or removing samples, do so carefully to avoid damaging the furnace's delicate refractory material. Always close the furnace door gently, never slamming it.

Avoid Thermal Shock and High-Temperature Exposure

Never open the furnace door when the internal temperature is above 600°C. The sudden rush of intense heat can cause severe burns and create thermal shock, which can crack the furnace chamber or the sample itself.

Operational Integrity: Protecting the Furnace and Sample

During operation, your goal is to maintain stable conditions. This protects the equipment from damage and ensures your experimental results are reliable.

Respect Temperature and Time Limits

Do not exceed the maximum rated temperature of the furnace. Furthermore, avoid operating the furnace at its highest rated temperature for extended periods, as this shortens the life of the heating elements.

Prohibit Unsuitable Materials

Never attempt to bake liquids or pour molten metal directly into the furnace chamber. The rapid vaporization of liquids can create a dangerous pressure buildup, and spills can cause catastrophic damage.

Similarly, never place explosive or unrated dangerous materials inside the furnace.

Monitor for Abnormalities

Pay close attention to the temperature controller throughout the heating process. If you notice any abnormalities or unexpected temperature fluctuations, cut power immediately and investigate the cause.

Understanding the Risks and Key Safeguards

Recognizing the specific hazards allows you to appreciate the importance of each safety protocol. The primary risks are severe burns, fire, electrical shock, and pressure events.

The Risk of Severe Burns and Thermal Shock

The extreme temperatures are an obvious hazard. Direct contact causes severe burns, while opening the door at high temperatures can cause thermal shock to both you and the equipment. This is why PPE and temperature discipline are essential.

The Danger of Fire and Explosions

Placing flammable materials near the furnace or heating volatile substances inside it creates a significant risk of fire or explosion. A clear workspace and careful screening of samples mitigate this hazard.

The Hazard of Electrical Shock

Improper grounding or a faulty electrical setup can be lethal. Using a dedicated, properly grounded circuit is the most critical step in preventing electrical accidents.

The Importance of Maintenance and Calibration

Regularly inspect heating elements and the chamber for signs of wear. Ensure the temperature controller is accurately calibrated to prevent overheating and to guarantee the integrity of your work. Built-in features like over-temperature protection and alarms are crucial safety nets.

The Shutdown and Cooling Protocol

A safe procedure does not end when the heating cycle is complete. Proper shutdown is critical for operator safety and furnace longevity.

Safe Sample Removal

Once the cycle is finished, turn off the main power. Only remove samples after the furnace has cooled to a safe handling temperature, using the proper PPE.

Controlled Cooling

After turning off the power, slightly open the furnace door. This allows heat to dissipate in a controlled manner, preventing thermal shock to the refractory materials and allowing the furnace to cool down faster.

Proper Shutdown When Not in Use

When the furnace is not in use for an extended period, ensure the main power is cut and the door is closed. This protects the sensitive internal refractory materials from atmospheric moisture.

Applying These Principles to Your Work

Your specific focus will determine which precautions are most critical in your day-to-day operations.

- If your primary focus is personal safety: Prioritize wearing PPE at all times, never opening the door above 600°C, and ensuring the furnace is properly grounded.

- If your primary focus is equipment longevity: Adhere strictly to temperature limits, ensure controlled cooling by cracking the door, and perform regular maintenance checks.

- If your primary focus is experimental accuracy: Ensure the workspace is clean, the temperature controller is calibrated, and you monitor the operation closely for any abnormalities.

Ultimately, consistent and disciplined adherence to these safety protocols is the mark of a true professional.

Summary Table:

| Safety Aspect | Key Precautions |

|---|---|

| Environment Setup | Ensure proper electrical grounding, stable non-combustible surface, clear workspace free of flammables, adequate ventilation |

| Operator Protection | Wear heat-resistant gloves and safety goggles, avoid opening door above 600°C, handle materials carefully |

| Operational Integrity | Do not exceed maximum temperature, avoid liquids and explosives, monitor for abnormalities, perform regular maintenance and calibration |

| Shutdown and Cooling | Turn off power, allow controlled cooling by slightly opening door, remove samples only when safe |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability tailors equipment to your unique experimental needs, enhancing precision and durability. Contact us today to discuss how we can support your safety protocols and operational goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals