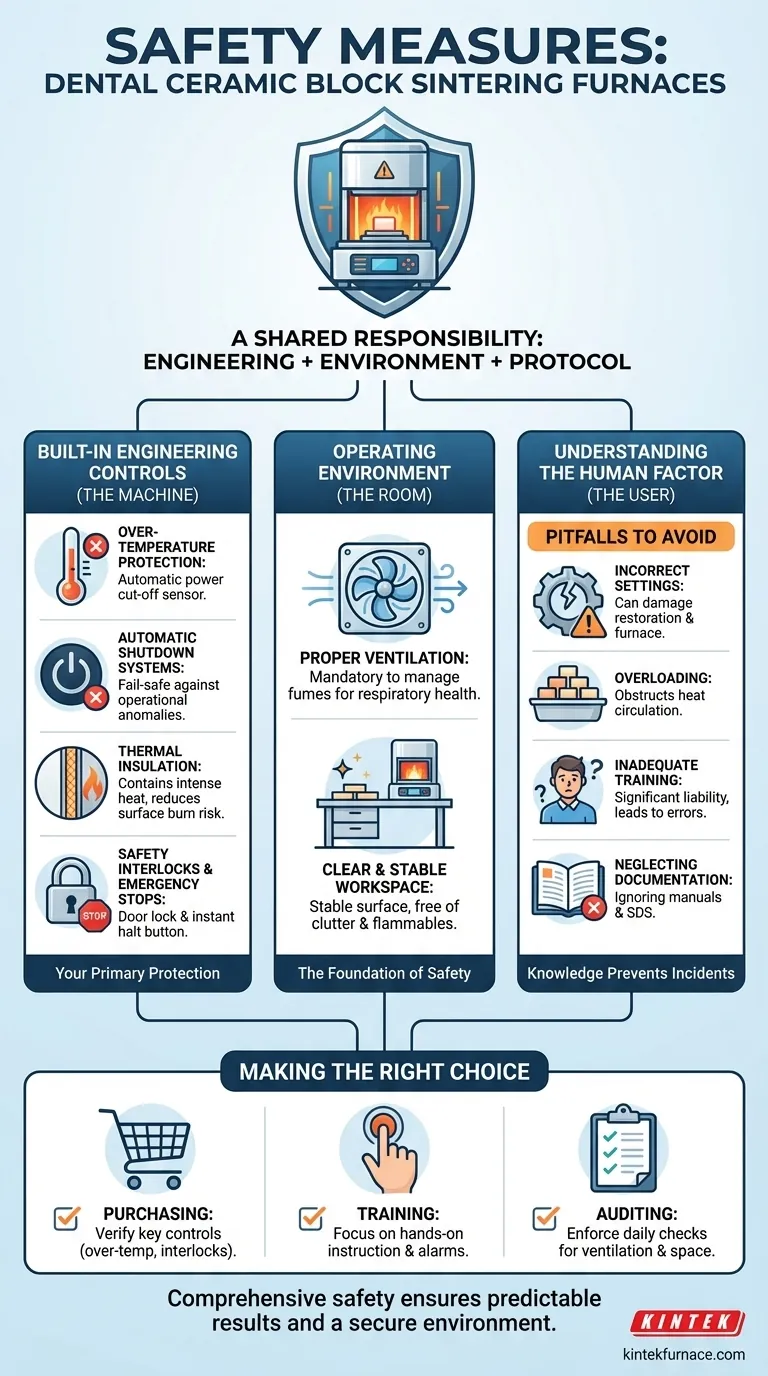

At its core, safety for dental ceramic block sintering furnaces relies on a combination of automated engineering controls, essential environmental setups, and rigorous operator protocols. The most critical measures include automatic over-temperature protection, thermal insulation, safety interlocks on the chamber door, and mandatory use in a well-ventilated area to manage fumes.

A sintering furnace is a powerful and essential piece of laboratory equipment, but its high-temperature operation presents inherent risks. True safety is not found in a single feature, but in a system of shared responsibility between the manufacturer's built-in protections and the user's disciplined operating procedures.

Built-in Engineering Controls: The Furnace's First Line of Defense

Manufacturers integrate several non-negotiable safety systems directly into the furnace design. These features are your primary protection against equipment failure and accidents.

Over-Temperature Protection

This is arguably the most critical automated safety feature. A dedicated sensor constantly monitors the internal temperature.

If the furnace exceeds its maximum safe operating temperature, this system automatically cuts power to the heating elements, preventing catastrophic overheating, damage to the furnace, and potential fire hazards.

Automatic Shutdown Systems

Beyond simple temperature monitoring, modern furnaces include logic that can shut the unit down if it detects other operational anomalies. This acts as a comprehensive fail-safe to protect both the restoration and the equipment itself.

Thermal Insulation

Sintering furnaces operate at extremely high temperatures. Thermal insulation is the material within the furnace walls that contains this intense heat.

Effective insulation serves two safety purposes: it ensures process stability and minimizes the external surface temperature of the unit, significantly reducing the risk of accidental contact burns for the operator.

Safety Interlocks and Emergency Stops

A safety interlock is a mechanism that prevents the furnace door from being opened while a heating cycle is active. This is a crucial feature that protects the user from exposure to extreme temperatures and potential thermal shock.

Additionally, many units are equipped with a physical emergency stop button that allows the operator to immediately halt all furnace operations in case of an unforeseen problem.

The Critical Role of the Operating Environment

A safe furnace is only as safe as the room it's in. The operational environment and placement are just as important as the machine's built-in features.

Proper Ventilation

Sintering certain ceramic materials at high temperatures can release fumes. Operating the furnace in a well-ventilated area is mandatory to prevent the buildup of potentially harmful airborne particulates and ensure operator respiratory health.

Clear and Stable Workspace

The furnace should be placed on a stable, level surface that can support its weight. The area around it must be kept clear of flammable materials and general clutter to prevent fire risk and ensure easy access to controls.

Understanding the Human Factor: Common Pitfalls to Avoid

Many safety incidents are not caused by equipment failure but by user error. Understanding these common mistakes is key to preventing them.

Incorrect Temperature and Cycle Settings

Every ceramic material has a precise sintering protocol provided by the manufacturer. Using incorrect temperature settings or cycle times can ruin the dental restoration and, in extreme cases, place undue stress on the furnace's heating elements.

Overloading the Furnace

Placing too many restorations in the sintering tray can obstruct proper heat circulation. This leads to inconsistent results and can cause the furnace to work harder than designed, potentially triggering overheating alarms or shortening the lifespan of components.

Inadequate Operator Training

A sintering furnace is not an intuitive "plug-and-play" device. Untrained personnel are a significant liability, as they are more likely to make errors in programming, loading, and responding to alarms. Formal training is an essential safety investment.

Neglecting Manufacturer Documentation

The user manual and Safety Data Sheets (SDS) provided with the furnace and ceramic materials are critical documents. They contain specific instructions for operation, maintenance schedules, and vital safety warnings that must be understood and followed.

Making the Right Choice for Your Goal

Your approach to furnace safety should be proactive and tailored to your specific responsibilities within the lab.

- If you are purchasing a new furnace: Verify that it includes key engineered controls like over-temperature protection, a door interlock system, and robust thermal insulation.

- If you are training new staff: Focus on hands-on instruction covering proper loading, programming according to material specifications, and the explicit "what to do" for any error message or alarm.

- If you are auditing your lab's safety: Create and enforce a Standard Operating Procedure (SOP) that includes daily checks for ventilation and workspace clearance before any cycle is started.

Prioritizing this comprehensive system of safety ensures predictable, high-quality results and a secure environment for your entire team.

Summary Table:

| Safety Measure | Key Features | Purpose |

|---|---|---|

| Over-Temperature Protection | Automatic power cut-off | Prevents overheating and fire hazards |

| Thermal Insulation | Heat containment in walls | Reduces external surface temperature and burn risks |

| Safety Interlocks | Door lock during cycles | Prevents exposure to high temperatures |

| Ventilation Requirements | Well-ventilated area setup | Manages fumes for respiratory safety |

| Operator Training | Hands-on instruction | Reduces user error and ensures protocol adherence |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, enhancing productivity and minimizing risks. Contact us today to discuss how we can support your safety goals!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations