At its core, a muffle furnace is a high-temperature oven used to heat materials in a controlled environment without direct contact with flames or heating elements. This isolation is critical for a wide range of material testing and sample preparation procedures, from determining the ash content in food to preparing environmental samples for pollutant analysis.

The primary value of a muffle furnace is its ability to thermally treat a sample in a clean, controlled chamber. This prevents contamination from the heat source, ensuring that any changes in the material—or what remains of it—are a direct result of the high temperature alone.

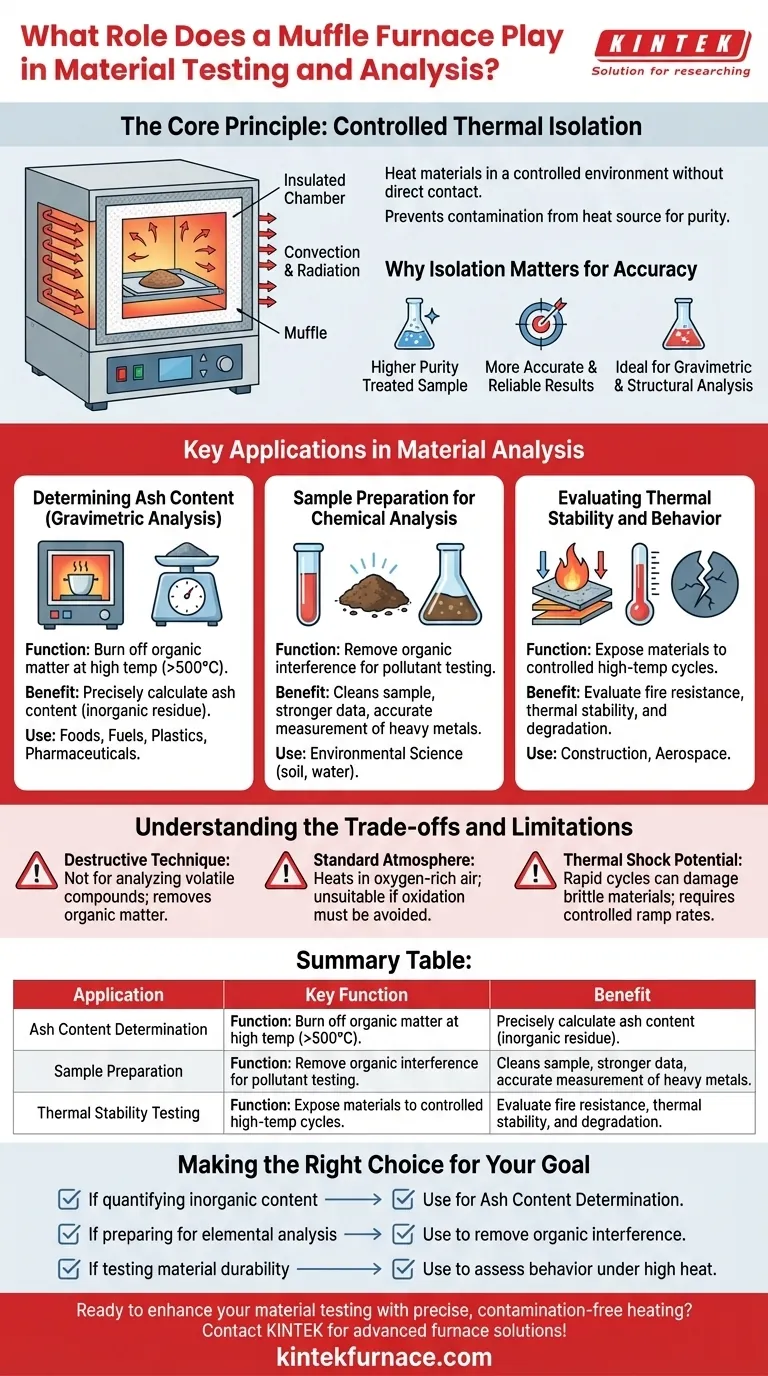

The Core Principle: Controlled Thermal Isolation

The function of a muffle furnace is defined by its unique construction. Understanding this design is key to understanding its role in the laboratory.

What is a "Muffle"?

A muffle furnace contains an insulated chamber, or "muffle," that houses the sample. The heating elements are located outside this chamber.

This design creates a critical separation. The sample is heated by convection and radiation, not by direct contact with the source of combustion or electrical heating elements.

Why Isolation Matters for Accuracy

This separation is the furnace's key advantage. It prevents byproducts from the heating source, such as soot or gases, from contaminating the sample.

As a result, the purity of the treated sample is significantly higher. This leads to more accurate and reliable experimental results, whether you are weighing what's left behind or analyzing the material's structural changes.

Key Applications in Material Analysis

The ability to apply pure, high heat makes the muffle furnace an indispensable tool across many scientific and industrial fields.

Determining Ash Content (Gravimetric Analysis)

One of the most common applications is ashing. The furnace heats a sample to a high temperature (often above 500°C) to completely burn off all organic and volatile substances.

The non-combustible, inorganic residue that remains is known as ash. By weighing the sample before and after this process, analysts can precisely calculate the ash content, a critical quality metric for foods, fuels, plastics, and pharmaceuticals.

Sample Preparation for Chemical Analysis

In environmental science, muffle furnaces are used to prepare samples for pollutant testing. Many pollutants of interest, such as heavy metals, are inorganic.

By ashing a soil or water residue sample, analysts can efficiently remove the complex organic matter that can interfere with sensitive analytical instruments. This "cleans up" the sample, providing stronger data and more accurate measurements of the target pollutants.

Evaluating Thermal Stability and Behavior

Engineers and material scientists use muffle furnaces to understand how materials perform under extreme thermal stress.

By exposing a material to controlled high-temperature cycles, they can evaluate its fire resistance, thermal stability, and points of degradation. This is essential for developing safer and more durable products, from construction materials to aerospace components.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is a specialized tool, and it's important to recognize its limitations.

Not for Analyzing Volatile Compounds

A muffle furnace is a destructive technique designed to remove organic and volatile matter. It is the wrong tool if your goal is to study the substances that are being burned off.

Standard Atmosphere is Air

A standard muffle furnace heats the sample in a normal air atmosphere, which is rich in oxygen. This is ideal for combustion and ashing applications.

However, if you need to heat a material without it oxidizing, you require a more specialized furnace capable of maintaining an inert atmosphere (like nitrogen or argon) or a vacuum.

Thermal Shock Potential

The rapid heating and cooling cycles can induce thermal shock, which may crack or damage certain brittle materials like ceramics. Proper programming of the temperature ramp rate is essential to mitigate this risk.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align the furnace's capabilities with your analytical objective.

- If your primary focus is quantifying inorganic content: A muffle furnace is the industry-standard tool for determining the ash content of a material through complete combustion.

- If your primary focus is preparing samples for elemental analysis: Use a muffle furnace to eliminate organic interference and improve the accuracy of subsequent tests for inorganic compounds like heavy metals.

- If your primary focus is testing a material's durability: A muffle furnace provides a repeatable, controlled environment to assess how a material will behave or degrade when exposed to high heat.

Ultimately, a muffle furnace empowers you to isolate the effects of heat on a material, providing clear and accurate data for critical analysis.

Summary Table:

| Application | Key Function | Benefit |

|---|---|---|

| Ash Content Determination | Burns off organic matter to measure inorganic residue | Accurate gravimetric analysis for quality control |

| Sample Preparation | Removes organic interference for pollutant testing | Enhanced data accuracy in environmental analysis |

| Thermal Stability Testing | Exposes materials to controlled high temperatures | Reliable evaluation of fire resistance and durability |

Ready to enhance your material testing with precise, contamination-free heating? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our muffle furnaces can deliver reliable results for your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?