In short, vacuum furnaces are essential for modern manufacturing because they create an ultra-clean, controlled environment for heating materials. By removing air and other gases, these furnaces prevent unwanted chemical reactions like oxidation, allowing for the creation of higher-purity, higher-performance components that would be impossible to produce in a standard atmospheric furnace.

The core value of a vacuum furnace is not just heating; it is achieving absolute control. By eliminating the reactive elements in the atmosphere, you unlock the ability to manufacture materials and components with superior purity, strength, and specific properties required by high-tech industries.

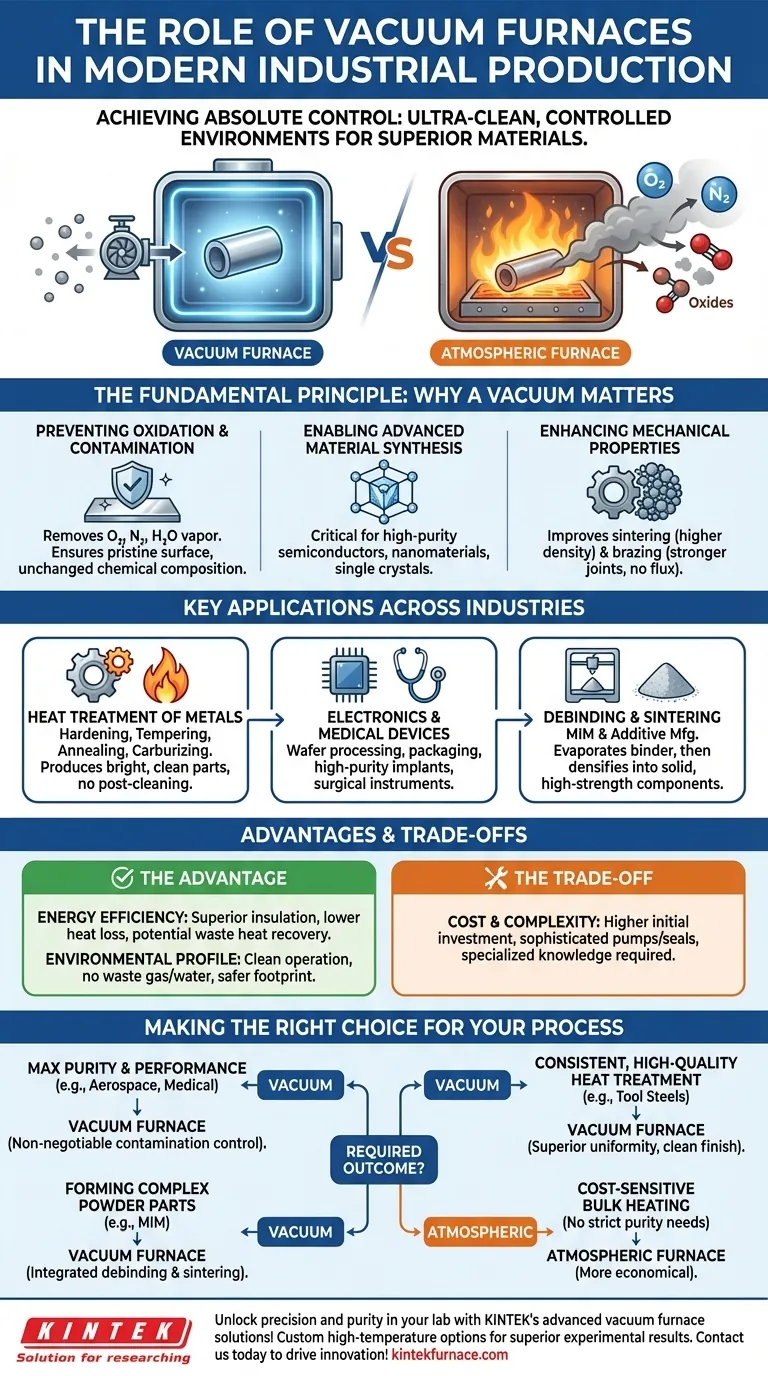

The Fundamental Principle: Why a Vacuum Matters

At its core, a vacuum furnace is a chamber where the atmospheric pressure has been significantly reduced. This seemingly simple act of removing air fundamentally changes the outcome of high-temperature processes.

Preventing Oxidation and Contamination

When materials, especially metals, are heated in the presence of oxygen, they oxidize. This creates a scale or oxide layer on the surface, which can compromise the material's integrity, dimensions, and performance.

A vacuum environment removes the oxygen, nitrogen, and water vapor that cause these unwanted reactions. This ensures the material's surface remains pristine and its chemical composition unchanged.

Enabling Advanced Material Synthesis

The creation of next-generation materials, such as single-crystal structures for semiconductors or highly pure superconducting materials, demands an environment free from impurities.

Vacuum furnaces provide this ideal, high-purity environment. They are critical for processes like crystal growth and the manufacturing of nanomaterials, where even trace amounts of contaminants can ruin the final product.

Enhancing Mechanical Properties

Processes like sintering (fusing powdered materials together with heat) and brazing (joining materials with a filler metal) are significantly improved in a vacuum.

Vacuum sintering results in components with higher density, fewer internal voids, and superior mechanical strength. Similarly, vacuum brazing creates stronger, cleaner joints without the need for corrosive fluxes.

Key Applications Across Industries

The ability to precisely control the heating environment makes vacuum furnaces indispensable in a wide range of critical manufacturing sectors.

Heat Treatment of Metals

Vacuum furnaces are widely used for the heat treatment of steel alloys and other metals to achieve specific hardness, strength, and durability.

Processes like hardening, tempering, and annealing performed in a vacuum produce bright, clean parts that require no subsequent cleaning. Vacuum carburizing (case hardening) creates an exceptionally uniform and controllable hardened surface layer.

Electronics and Medical Devices

The manufacturing of high-performance electronics relies heavily on vacuum technology. Furnaces are essential for semiconductor wafer processing, including diffusion and oxidation, as well as for packaging and testing integrated circuits.

Likewise, producing medical implants and high-precision surgical instruments requires materials that meet stringent purity and performance standards, a task perfectly suited for vacuum processing.

Debinding and Sintering

In metal injection molding (MIM) and additive manufacturing, a "green" part is often formed with a polymer binder. A vacuum furnace is used for debinding, a process that carefully evaporates this binder without disturbing the part's delicate structure.

This is immediately followed by sintering in the same furnace, which densifies the part into a solid, high-strength final component.

Understanding the Advantages and Trade-offs

While powerful, vacuum furnaces represent a specific choice with clear benefits and considerations compared to atmospheric furnaces.

The Advantage: Energy Efficiency

Modern vacuum furnaces are designed with superior thermal insulation, which drastically reduces heat loss to the surrounding environment. This results in a much higher energy utilization rate.

Some advanced systems even incorporate waste heat recovery technology, further improving their efficiency and lowering operational costs over time.

The Advantage: Environmental Profile

Because the process is contained within a sealed chamber, vacuum furnaces do not produce waste gas, wastewater, or other pollutants common to traditional heat treatment methods.

This clean operation simplifies environmental compliance and contributes to a safer, more sustainable manufacturing footprint.

The Trade-off: Cost and Complexity

The primary trade-off is the higher initial investment and operational complexity. Creating and maintaining a high-quality vacuum requires sophisticated pumps, seals, and control systems.

This means vacuum furnaces are typically more expensive to purchase and require more specialized knowledge to operate and maintain than their atmospheric counterparts. However, the superior quality of the final product often justifies the cost.

Making the Right Choice for Your Process

Deciding whether to use a vacuum furnace depends entirely on the required outcome for your material or component.

- If your primary focus is maximum purity and performance: For aerospace, medical, or semiconductor applications, the contamination control of a vacuum furnace is non-negotiable.

- If your primary focus is consistent, high-quality heat treatment: For tool steels or high-stress mechanical parts, vacuum processing provides superior uniformity and a clean finish that reduces post-processing steps.

- If your primary focus is forming complex parts from powders: For processes like MIM or binder jetting, the integrated debinding and sintering capabilities of a vacuum furnace are essential.

- If your primary focus is cost-sensitive bulk heating with no strict purity needs: A traditional atmospheric furnace may be a more economical choice.

Ultimately, investing in vacuum furnace technology is a strategic decision to prioritize quality, consistency, and the creation of advanced materials.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Principle | Removes air and gases to prevent oxidation and contamination, enabling precise control in high-temperature processes. |

| Key Applications | Heat treatment (e.g., hardening, annealing), electronics manufacturing, medical devices, debinding and sintering. |

| Advantages | High energy efficiency, clean environmental profile, superior purity, and enhanced mechanical properties. |

| Trade-offs | Higher initial cost and operational complexity compared to atmospheric furnaces. |

Unlock precision and purity in your lab with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for superior results. Contact us today to discuss how our solutions can enhance your industrial processes and drive innovation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety