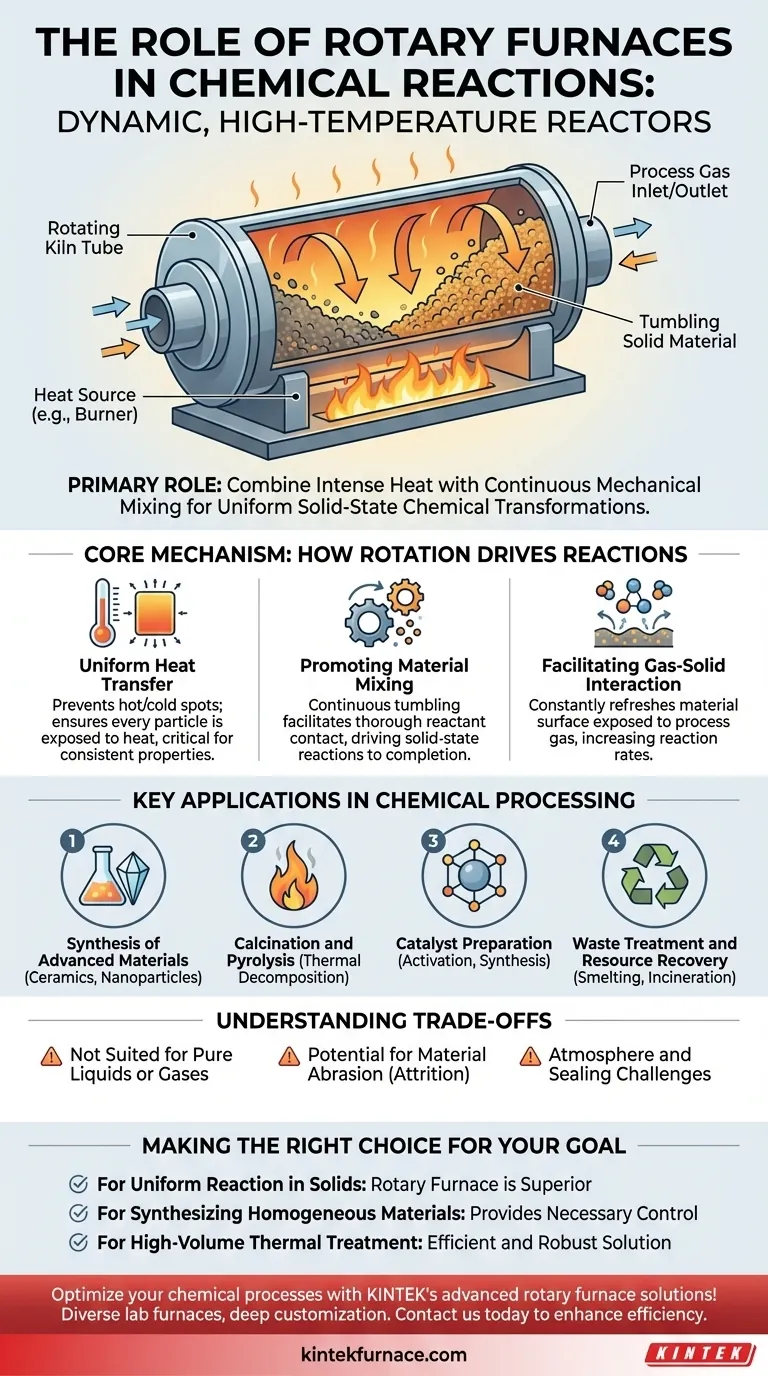

In chemical reactions, a rotary furnace acts as a dynamic, high-temperature reactor for processing solid materials. Its primary role is to combine intense heat with continuous mechanical mixing, ensuring that chemical transformations like synthesis, calcination, or pyrolysis occur uniformly and completely throughout the bulk material.

The crucial insight is that a rotary furnace's value isn't just in the heat it provides, but in its constant rotation. This tumbling motion guarantees uniform heat exposure and reactant mixing, which is the key to achieving consistent results in solid-state chemical reactions.

The Core Mechanism: How Rotation Drives Reactions

A rotary furnace is fundamentally different from a static furnace. Its rotating tube, or kiln, is the engine that facilitates specific chemical outcomes by physically manipulating the material being processed.

Ensuring Uniform Heat Transfer

The constant tumbling exposes every particle of the material to the heat source and the hot furnace walls. This prevents the formation of hot spots on the exterior and cold, unreacted cores within the material bed.

This uniformity is critical for reactions where temperature control directly dictates the final product's properties, phase, and purity.

Promoting Material Mixing

For solid-state reactions to occur, reactants must be in close physical contact. The cascading and rolling motion inside the furnace continuously mixes the powders or granules.

This ensures that different components react with each other thoroughly, driving the reaction to completion far more efficiently than a static process would allow.

Facilitating Gas-Solid Interaction

Many chemical processes, like roasting or calcination, require interaction between the solid material and a specific gas atmosphere.

Rotation constantly refreshes the surface of the material exposed to the process gas. This dramatically increases the rate of reactions such as oxidation, reduction, or the removal of volatile compounds like water and carbon dioxide.

Key Applications in Chemical Processing

The unique combination of heat and motion makes rotary furnaces exceptionally versatile. They are a cornerstone technology in materials science, metallurgy, and environmental industries.

Synthesis of Advanced Materials

Rotary furnaces are used to create new materials with precise chemical and structural properties. This includes the synthesis of high-performance ceramics, metal powders for sintering, and advanced materials like nanoparticles.

The controlled environment ensures the final product is homogenous and meets strict specifications.

Calcination and Pyrolysis

Calcination is a process of heating a solid to a high temperature to cause a chemical change or drive off volatile substances. Pyrolysis is thermal decomposition in the absence of oxygen.

Rotary furnaces excel at these tasks, especially for granular or powdered materials. They are widely used in chemical processing and for recovering valuable substances from industrial byproducts.

Catalyst Preparation

The performance of a chemical catalyst often depends on its structure and surface area.

Using a rotary furnace allows for the precise thermal treatment needed to activate catalysts or synthesize them, ensuring uniform properties that are essential for their catalytic activity.

Waste Treatment and Resource Recovery

In metallurgy and environmental management, rotary furnaces are workhorses. They are used for smelting metals from ores, recovering lead from battery scrap, and safely incinerating hazardous waste.

The robust nature and efficient mixing of these furnaces make them ideal for handling heterogeneous materials like industrial scrap and byproducts.

Understanding the Trade-offs

While powerful, rotary furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Not Suited for Liquids or Gases

The design is optimized for processing solids, powders, and slurries. They are not the appropriate tool for purely liquid-phase or gas-phase reactions, where other reactor types like CSTRs or packed beds are superior.

Potential for Material Abrasion

The continuous tumbling action can be a disadvantage for very delicate or friable materials. This mechanical stress can cause particle breakdown (attrition), which may be undesirable for certain applications.

Atmosphere and Sealing Challenges

While a controlled atmosphere is achievable, maintaining a perfect, hermetic seal on a large, rotating piece of equipment can be more complex and costly than with a static batch furnace. This is a consideration for reactions requiring extremely high-purity inert atmospheres.

Making the Right Choice for Your Goal

Selecting a thermal processing method depends entirely on your material's form and the desired chemical outcome.

- If your primary focus is achieving a uniform reaction in a solid powder or granule: A rotary furnace is the superior choice for ensuring complete mixing and consistent heat distribution.

- If your primary focus is synthesizing homogeneous materials like ceramics or catalysts: The dynamic environment of a rotary furnace provides the control needed to produce materials with consistent properties.

- If your primary focus is high-volume thermal treatment of bulk solids or waste: The continuous processing capability and robust design of an industrial rotary furnace make it the most effective solution.

Ultimately, the rotary furnace's unique ability to combine heat with constant motion makes it an indispensable tool for manipulating the chemistry of solid materials.

Summary Table:

| Aspect | Role in Chemical Reactions |

|---|---|

| Uniform Heat Transfer | Prevents hot spots and cold cores for consistent temperature control. |

| Material Mixing | Ensures thorough reactant contact for complete solid-state reactions. |

| Gas-Solid Interaction | Enhances reaction rates by refreshing material surfaces with process gases. |

| Key Applications | Synthesis, calcination, pyrolysis, catalyst preparation, and waste treatment. |

Optimize your chemical processes with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for solid-state reactions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to enhance efficiency and achieve consistent results in your applications!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput